High-voltage discharging rod

A high-voltage discharge and discharge rod technology, applied in corona discharge devices, circuits, electrical components, etc., can solve problems such as safety hazards, insufficient voltage resistance of insulating rods, wire wear, etc., to achieve convenient installation and transportation, improve safety and reliability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

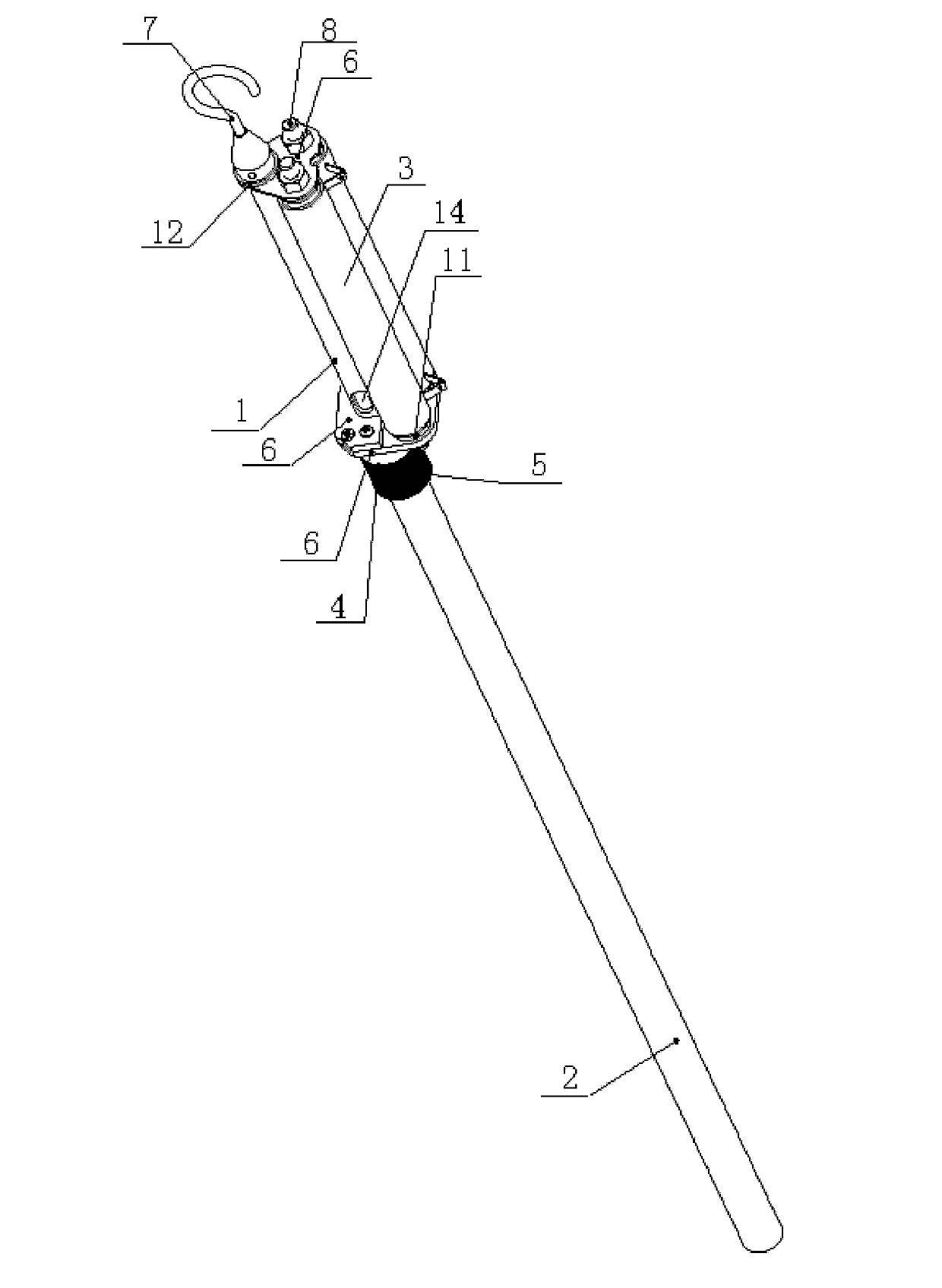

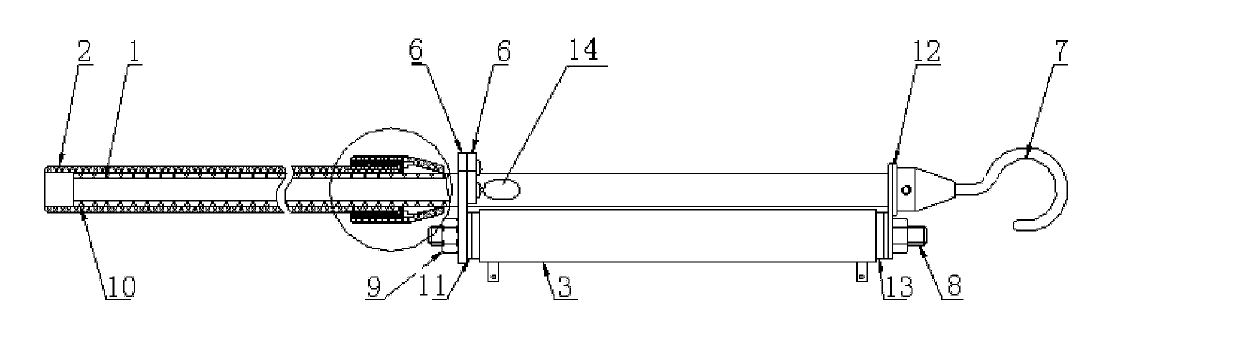

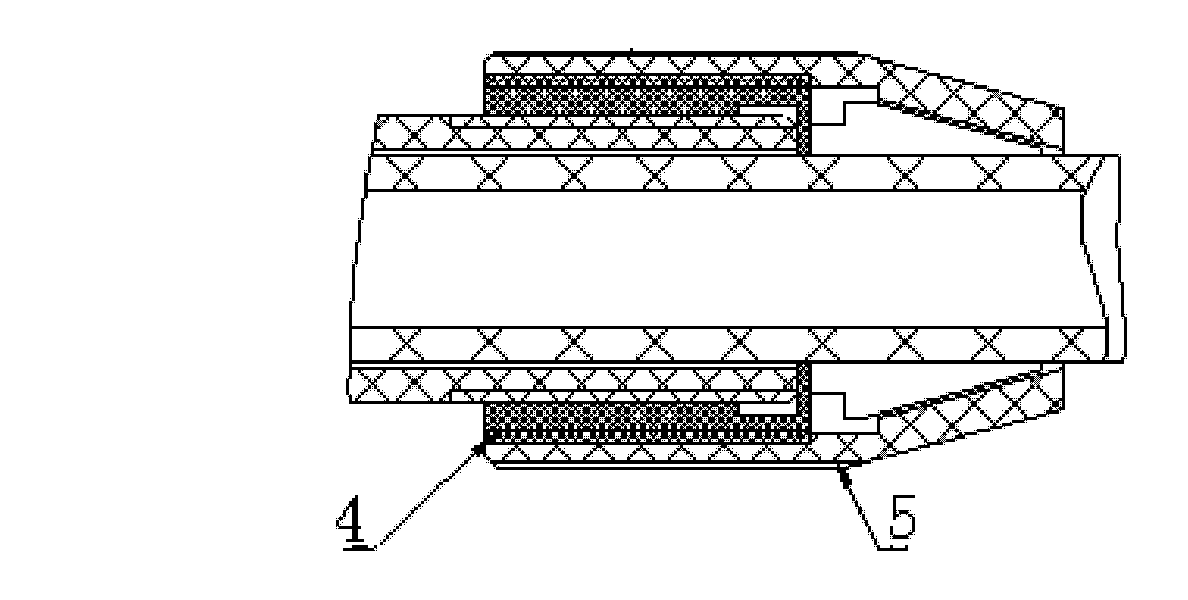

[0022] Such as figure 1 As shown, the present invention is that the inner rod 1 of the discharge rod and the outer rod 2 of the discharge rod are mutually fitted, and the inner rod 1 of the discharge rod and the outer rod 2 of the discharge rod are both hollow structures; the inner rod 1 of the discharge rod is connected to the discharge resistor 3 through a support plate 6 , and its top is connected with a discharge hook 7; one end of the discharge resistor 3 is connected to the discharge hook 7, and the other end is connected to the ground wire and passes through the inner cavity of the inner rod 1 of the discharge rod and the outer rod 2 of the discharge rod, thereby passing through the discharge rod The mutual cooperation between the inner rod 1 and the outer rod 2 of the discharge rod adjusts the length of the entire discharge rod, and leads the ground wire out of its inner cavity to protect the ground wire. The discharge resistor 3 is a power type wirewound resistor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com