Electric connector, manufacturing method thereof and coating manufacturing method

A technology for electrical connectors and manufacturing methods, applied in the direction of connection, fixed connection, and parts of connection devices, can solve problems such as electromagnetic interference, a large number of terminals, and affecting the electrical conduction function of a circuit board, and achieve good electrical performance. Conduction function, the effect of avoiding electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The electrical connector of the present invention, its manufacturing method and coating manufacturing method will be further described below in conjunction with the accompanying drawings and specific embodiments.

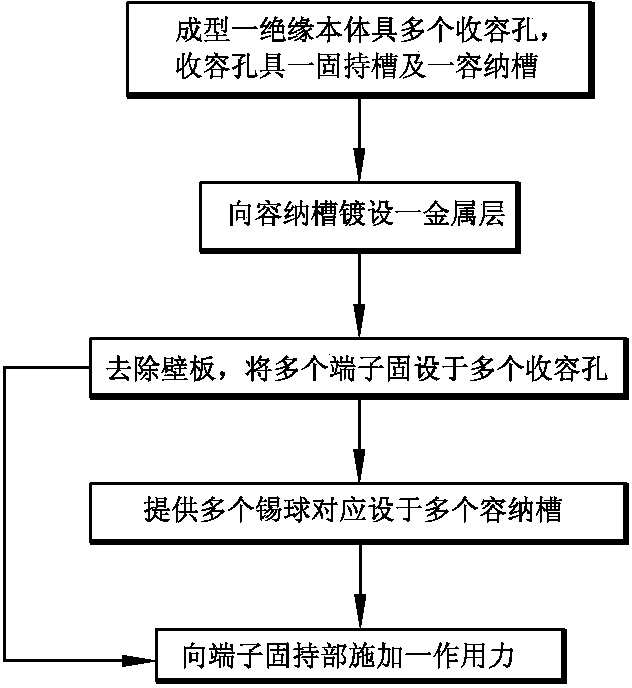

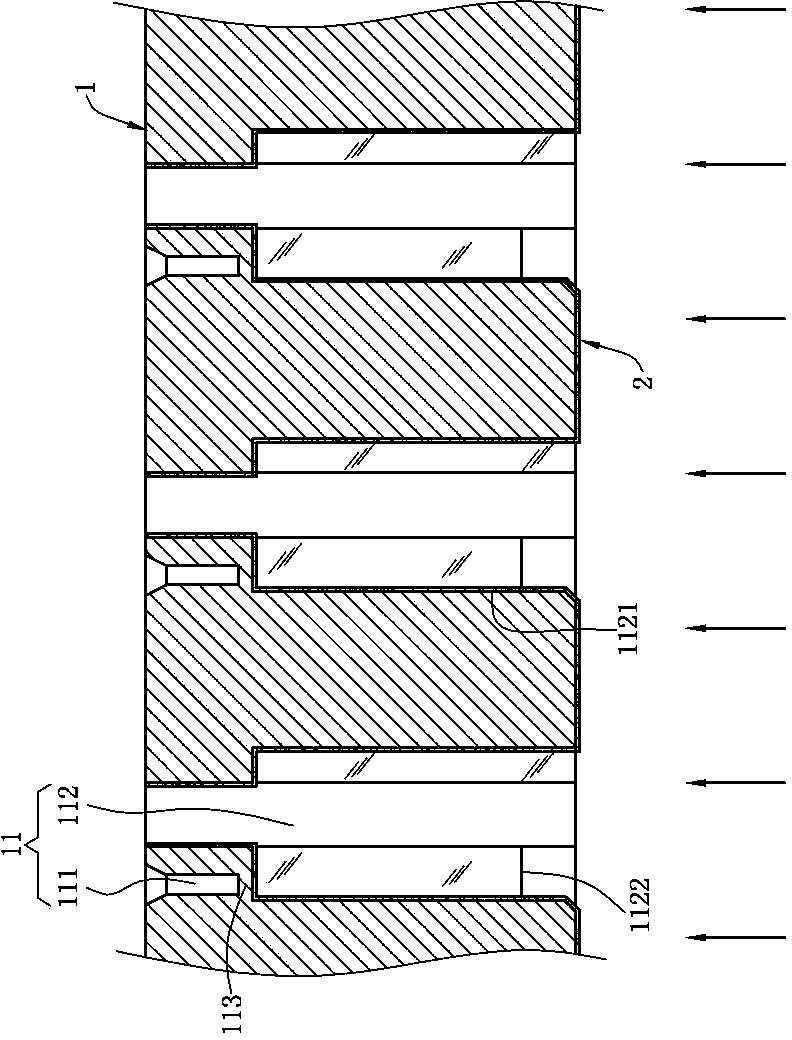

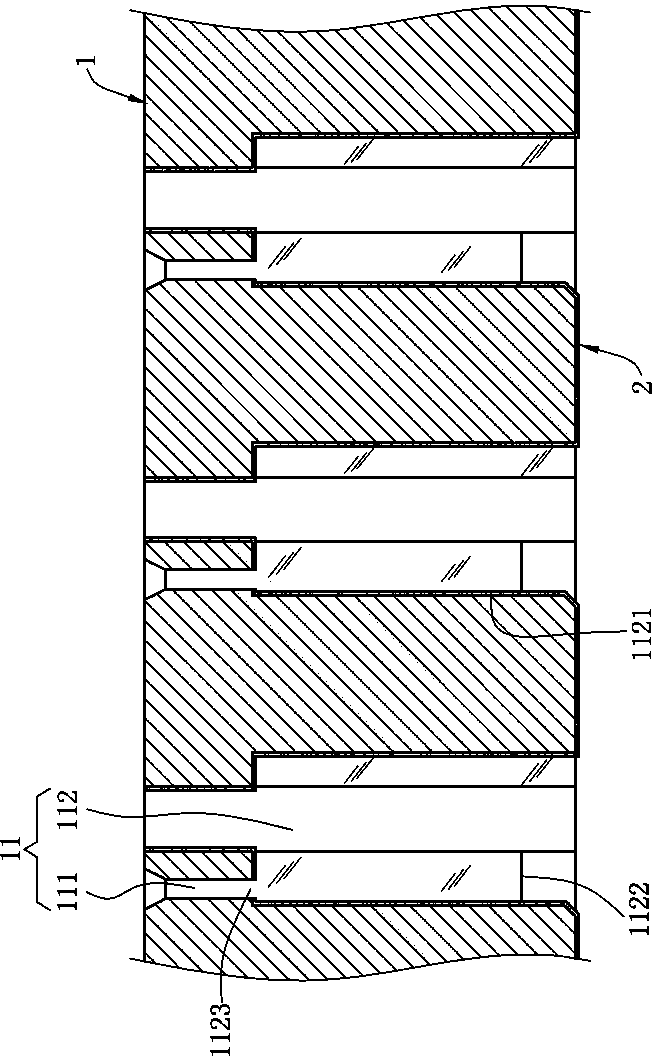

[0039] The invention discloses a manufacturing method of an electrical connector, the manufacturing method of the electrical connector includes the following steps: please refer to figure 1 and figure 2 , forming an insulating body 1 so that it has a plurality of receiving holes 11, each of the receiving holes 11 has a holding groove 111 and a receiving groove 112, and a wall is provided between the holding groove 111 and the receiving groove 112 plate 113.

[0040] see figure 1 and figure 2 , a metal layer 2 is plated, and the metal layer 2 is plated on the accommodating tank 112 so that the metal layer 2 covers the inner wall 1121 of the accommodating tank 112 . The metal layer 2 is formed by sputtering, of course, in other embodiments, the metal laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com