Simulated movable comb-shaped branch/leaf skeleton and manufacturing method thereof

A production method and comb-shaped technology, applied in clothing, applications, artificial flowers, etc., can solve problems such as inability to swing with the wind, short service life, poor wind resistance, etc., to enhance load capacity and wind resistance, and eliminate wind Dynamic stress fatigue and strong plastic deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

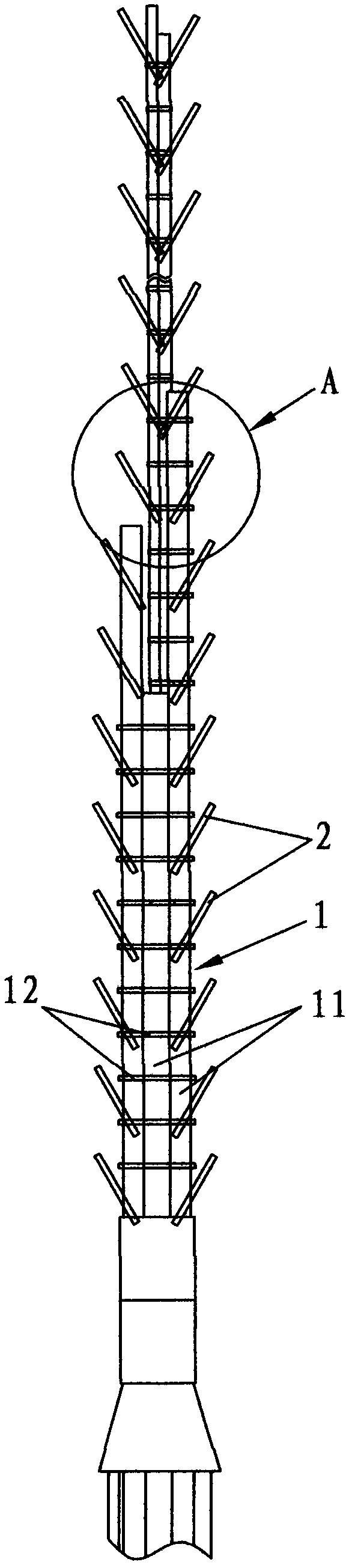

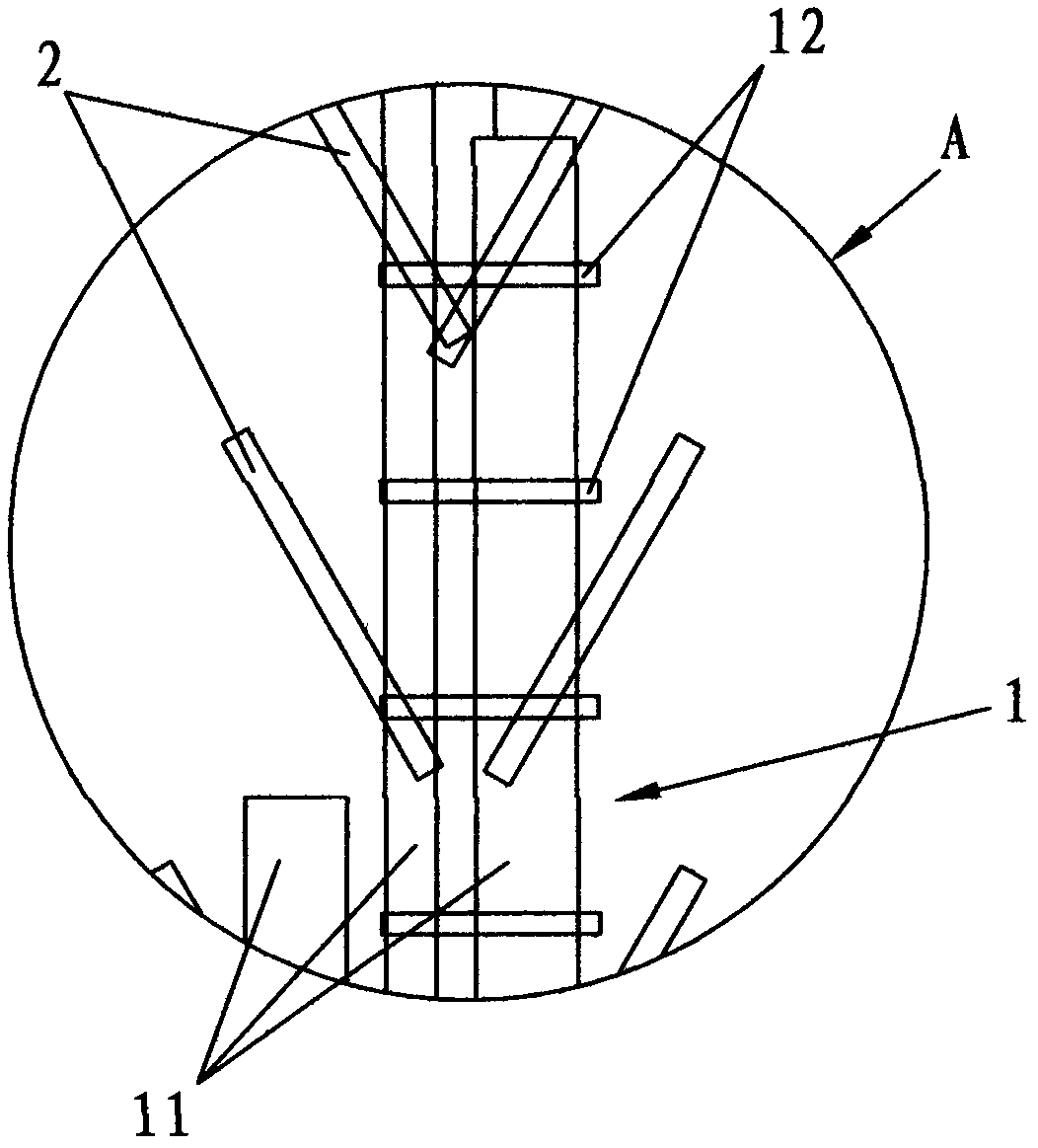

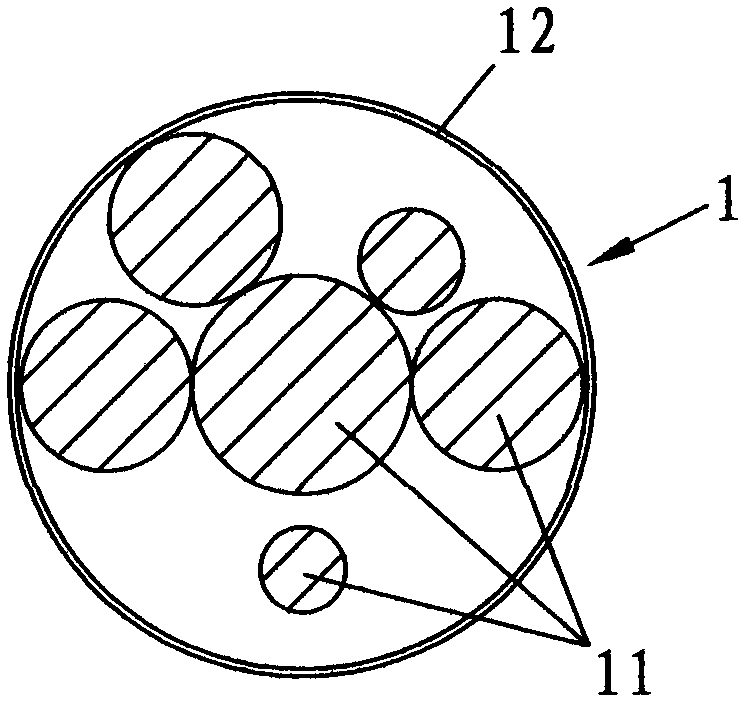

[0022] The present invention will be further described below in conjunction with the accompanying drawings, see Figure 1~3 As shown, the simulation dynamic comb-shaped branch and leaf skeleton includes a branch rod 1 and a plurality of leaf rods 2 connected to the branch rod 1. When in use, the root of the branch rod 1 is inserted on the tree rod, and the blades are inserted on the leaf on rod 2. The branch rod 1 includes a plurality of circular spring steel bars 11, and the spring steel bars 11 have better elastic properties. Of course, the spring steel bars 11 can also be replaced by other elastic metal bars. The number and diameter of the spring steel bars 11 increase synchronously from the tail of the stem 1 to the root, that is, the diameter of the increased spring steel bars 11 also increases accordingly, and the root of each spring steel bar 11 extends to the root of the stem 1 . A plurality of steel wire hoops 12 are bundled outside the plurality of spring steel bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com