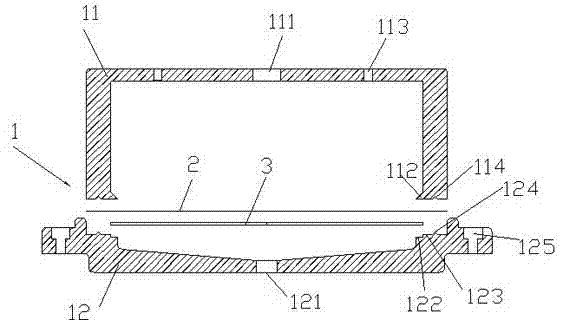

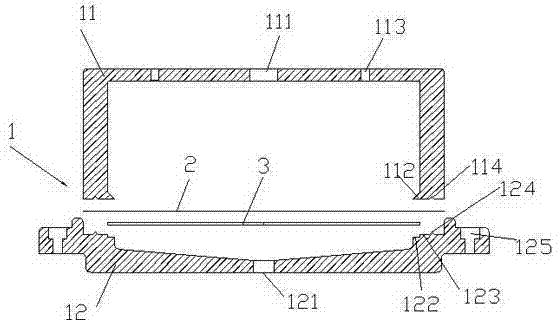

Expanded type liquid filter utensil

An unfolding, liquid technology, applied in the direction of fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of paper-like funnel tip penetration, low filtration efficiency, low utilization rate of filter paper, etc., and achieve high filtration speed Fast, easy to operate, improve the effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] The filter paper of the present invention is placed in an unfolded manner to maximize the filtration area and fundamentally improve the filtration efficiency. The stainless steel support net is used to avoid the penetration of the filter paper. Since the size of the filter dish is not limited by the size of the filter paper, it can be injected all at once. liquid to be filtered. In addition, the present invention is processed by metal materials, and can be easily extended to an automatic control device. The filter sheet in the present invention can also select filter gauze etc. as required, the present invention is not limited to a kind of embodiment, those skilled in the art, according to the technical general knowledge of this field, the equivalent deformation done on the basis of the present invention, all Should fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com