Gas shield welding wire for nuclear power

A technology of gas shielded welding and nuclear power, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of weld metal toughness decline, insufficient strength and toughness, etc., and achieve small welding spatter and stable mechanical properties , good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention is introduced in detail below:

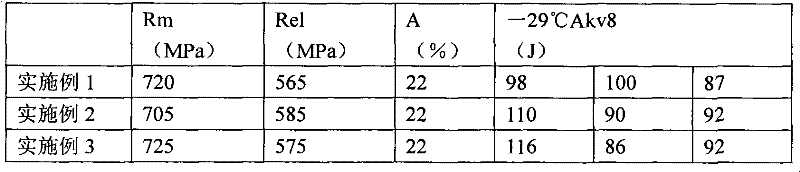

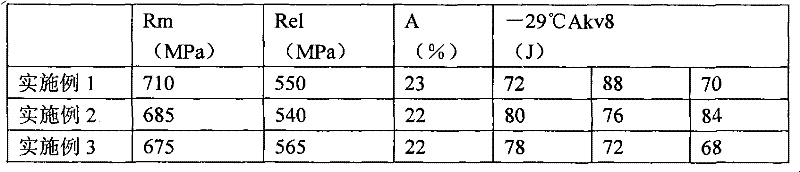

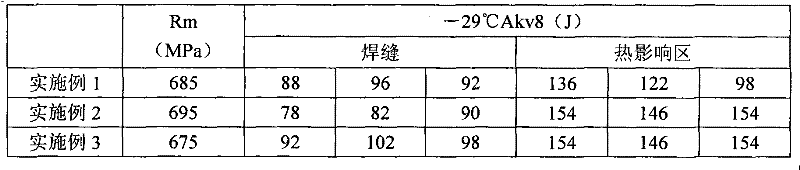

[0018] A 0.5-ton converter is used to smelt welding wire steel with low S and P raw materials. During the smelting process, the content of O, N and other gases in the steel is controlled. There is no special requirement for the smelting process. The specific components are shown in Table 1. After smelting, the welding wire steel is processed into a specification of Φ1.2mm through the processes of disc rolling, wire drawing, and surface copper plating. The welding wire is protected by a mixed gas (80%Ar+20%C02) for welding deposited metal tests. Welding process parameters The welding current is 220-260A, the welding voltage is 26-30V, the gas flow rate is 20L / min, and the welding input energy is 15-20KJ / cm. The mechanical properties are shown in Table 2. Table 3 shows the properties of the deposited metal of the welding wire after the annealing treatment at 593°C-620°C for not less than 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com