900MPa high-strength loop chain pulse flash butt welding process

A flash butt welding, 900mpa technology, applied in the direction of welding equipment, manufacturing tools, resistance welding equipment, etc., to achieve the effect of suppressing the tendency of hardening and cold cracking, high performance and good fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The steel for the ring chain is SAE8620H high-strength steel, and the specification is The high-strength ring chain is used for pulse flash butt welding, and the pulse flash butt welding machine is used for welding.

[0051] The specific welding process steps are as follows:

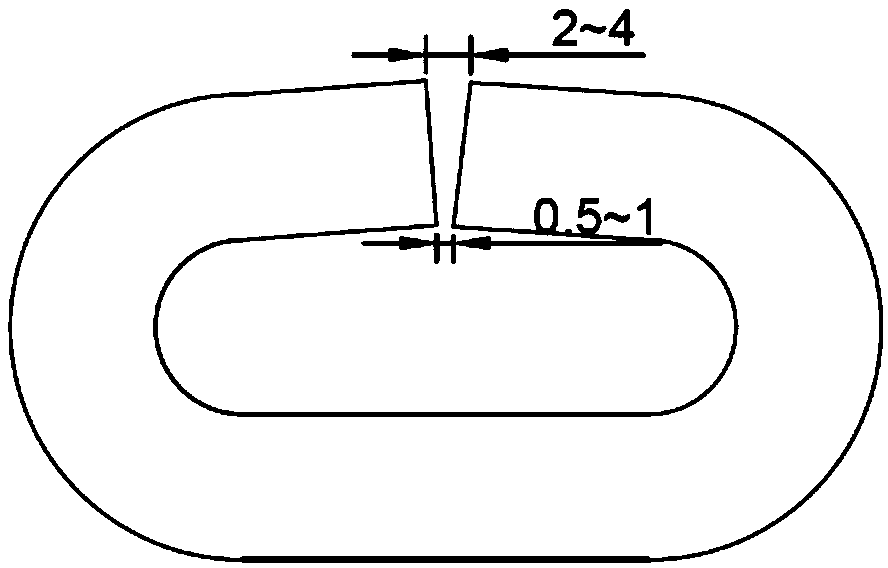

[0052] Process the SAE8620H bar to length on the Jh23-100 model punch After being annealed at 600℃×4h, put it into the BFBL-40-2A ring weaving machine, and then press it into a ring, and control the opening size of the ring interface. The inner ring is 0.5~1mm, and the outer ring is 2~ 4mm, the size structure diagram is as follows figure 1 shown.

[0053] Put the finished ring chain into the medium frequency induction heating furnace and heat it to 180-190°C, and the preheated ring chain is transported to the pulse flash butt welding machine through the auxiliary conveying device. It is sent to the flash butt welding station to be welded by a mechanical device, positioned and clamped to ente...

Embodiment 2

[0057] For specifications Pulse flash butt welding of the 900MPa high-strength link chain. The ring chain steel is 23MnNiMoCr54, which is welded by pulse flash welding machine.

[0058] The specific flash butt welding process steps are as follows:

[0059] The 23MnNiMoCr54 bar is processed into a 490±1.0mm bar on a Jh23-100 type punch, and after annealing at 620°C×4h, it is put into the BFBL-40-2A automatic ring weaving machine, and then the ring is automatically weaved. Control the opening size of the ring after weaving, the inner ring is 0.8~1.2mm, and the outer ring is 2.5~4.5mm.

[0060] Put the shot blasted ring chain into the medium frequency induction heating furnace and heat it to 190-200°C, and the preheated ring chain is transported to the pulse flash welding machine through the auxiliary conveying device. It is sent to the flash butt welding station to be welded by a mechanical device, positioned and clamped to enter the pulse flash butt welding stage. The proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com