Longitudinal adjusting and auxiliary welding line alignment device for welding gun of special circumferential welding machine for automotive transmission shaft

A technology for aligning devices and transmission shafts, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

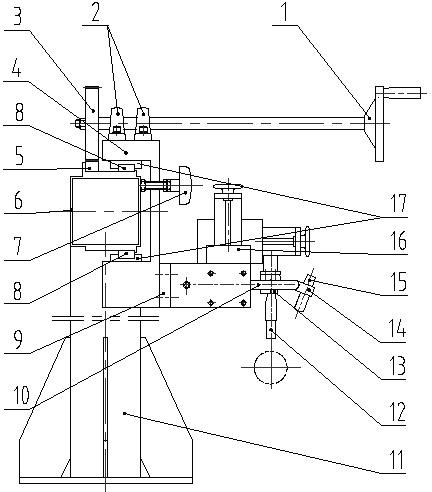

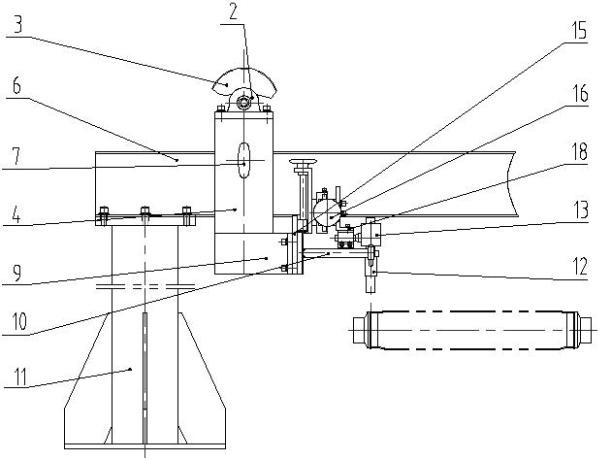

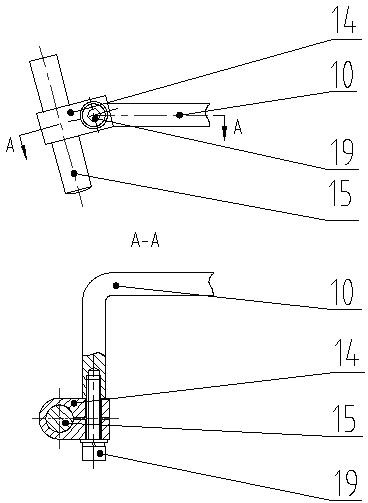

[0012] see figure 1 , figure 2 , image 3 : The longitudinal adjustment of the welding torch and the auxiliary welding seam alignment device of the special machine for girth welding of automobile transmission shafts. On the upper and lower planes of the two slides (17) respectively slide on the two linear guides (8), and the longitudinal slide (4) is fixedly installed on the slides (17); the welding torch adjustment assembly (16) is connected through the adjustment assembly (9) Installed on the front end of the longitudinal slide table (4), the bearing assembly (2) is fixedly installed above the longitudinal slide table (4), the handwheel shaft (1) is installed in the bearing assembly (2), and a gear (3) is installed at its rear end. ); a rack (5) is fixedly installed on the upper plane of the longitudinal beam (6), when the handwheel shaft (1) rotates, the gear (3) meshes with the rack (5), driving the longitudinal slide (4) along the longitudinal direction The beam (5) ...

Embodiment 2

[0014] This embodiment is basically the same as the first embodiment, and the special features are:

[0015] The longitudinal beam (6) is fixedly mounted on the structure of the foot (11); the left end of the longitudinal beam (6) is fixedly connected to the top panel of the foot (11) through bolts and nuts to form a cantilever structure.

[0016] The welding torch adjustment assembly (16) is a vertical position adjustment mechanism composed of a vertical handwheel screw matching nut and a longitudinal position adjustment mechanism composed of a longitudinally moving handwheel screw matching.

[0017] The working principle of this embodiment is as follows:

[0018] When installing and debugging the equipment, keep the longitudinal position of the laser transmitter and the welding torch on the same plane.

[0019] When it is necessary to adjust the longitudinal position of the welding torch, first loosen the locking bolt that locks the longitudinal moving slide, and manually r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com