On-site repairing method for SJ type air-intake sintering system

An on-site maintenance and winding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, and inconvenient maintenance methods, and achieve high maintenance efficiency, save maintenance costs, and use less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

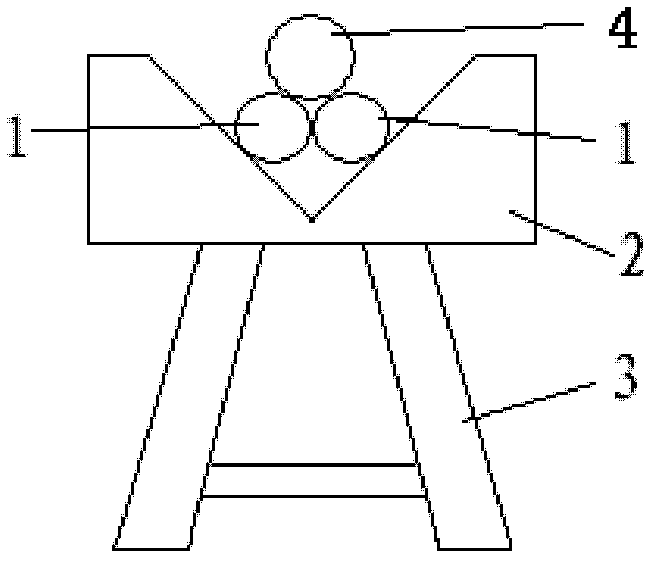

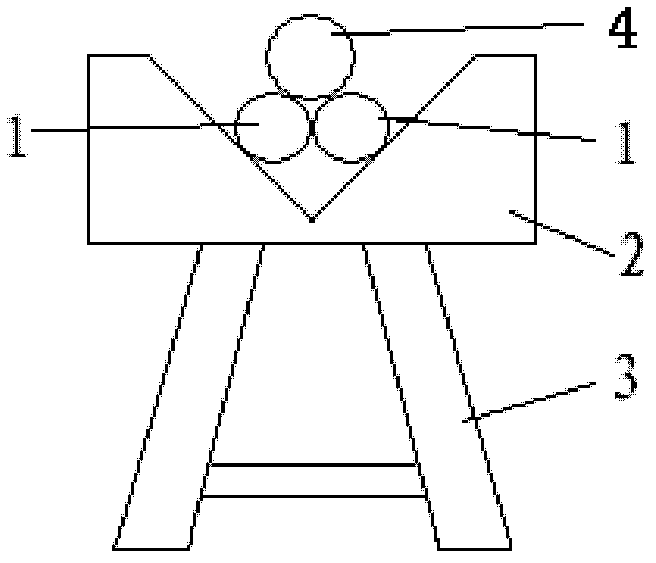

[0011] Such as figure 1 The structure of the simple bracket used in the method of the present invention is to include a mounting platform 2 provided with legs 3, and a V-shaped groove is provided on the upper surface of the mounting platform 2, and the two slopes in the V-shaped groove are respectively along the axis A cylinder 1 is placed in the direction, and the rotor to be repaired is placed on the two cylinders 1.

[0012] The field maintenance method of the present invention is implemented according to the following steps:

[0013] Step 1. After repairing the wear-resistant layer of the rotor to be repaired, place the rotor on two simple axially aligned supports. The rotor shaft 4 and the two cylinders 1 are kept in tangential contact with each other for static Balance test, rotate the rotor that needs to be repaired, repair the counterweight according to the static balance test results, until it reaches the static balance requirement of 10-20 grams;

[0014] Step 2. Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com