Radiator of gravity loop heat pipe, condenser and manufacturing method thereof

A loop heat pipe and condenser technology, used in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of excessive connection solder joints and low working reliability, and achieve high working reliability, The effect of strength guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

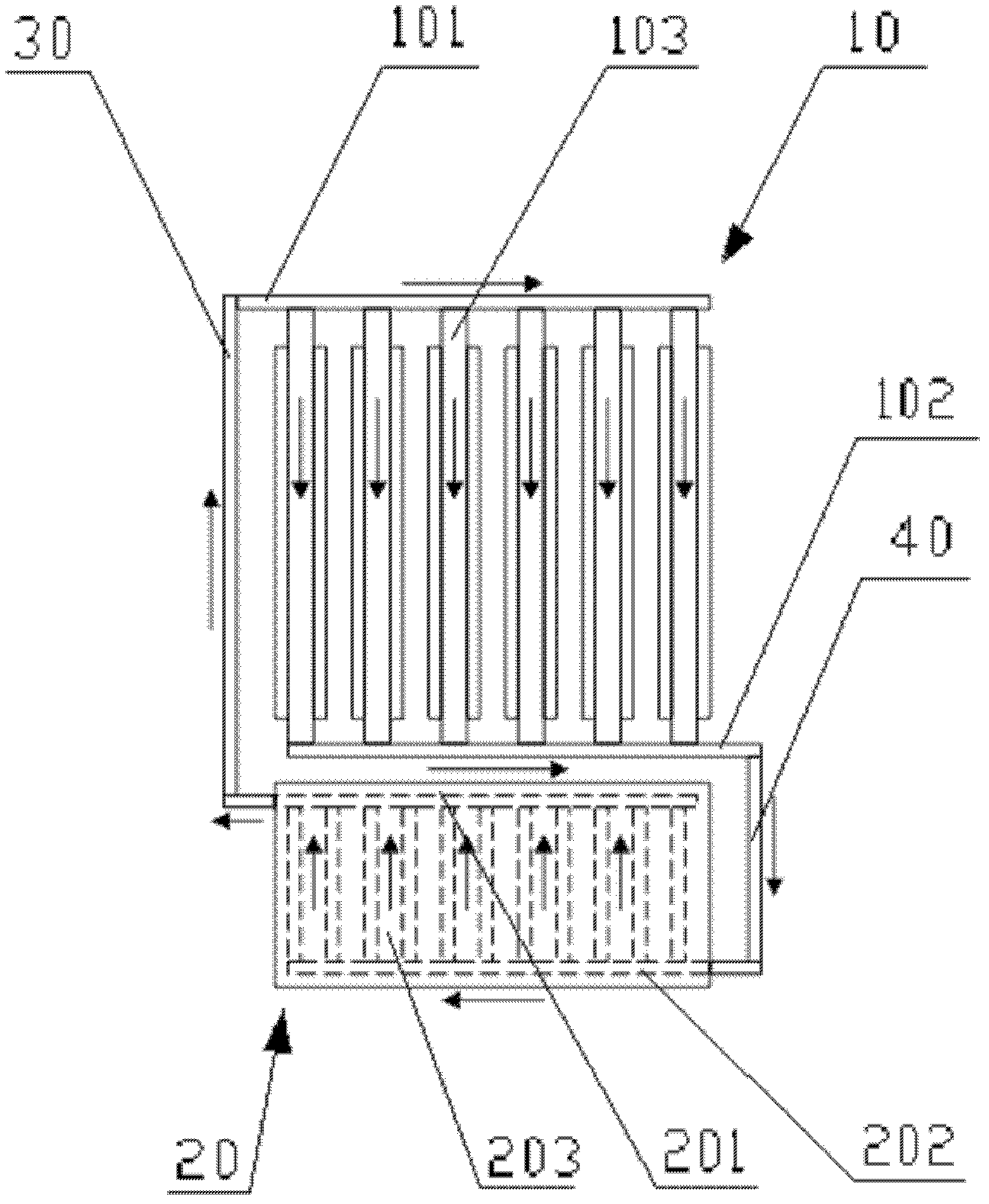

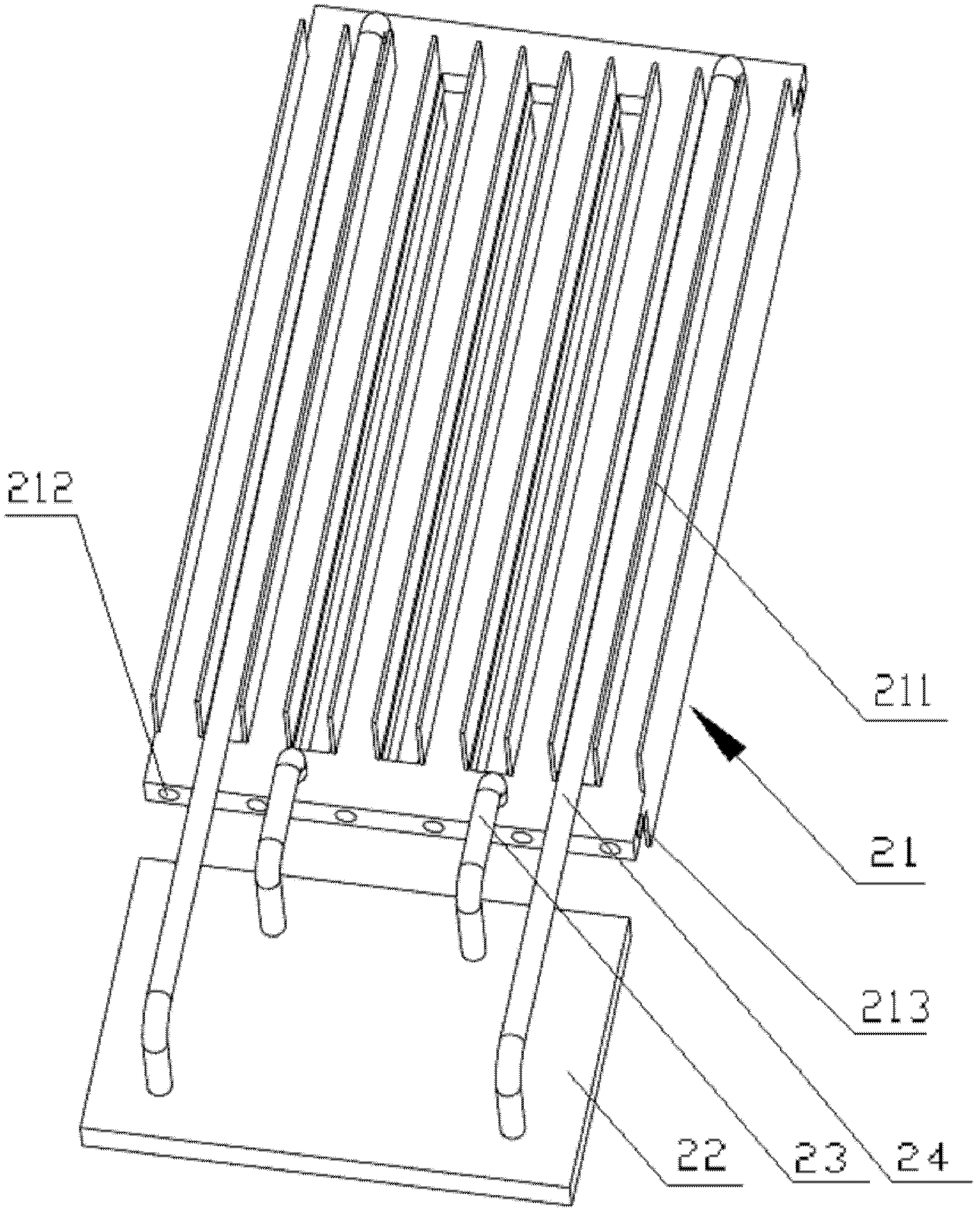

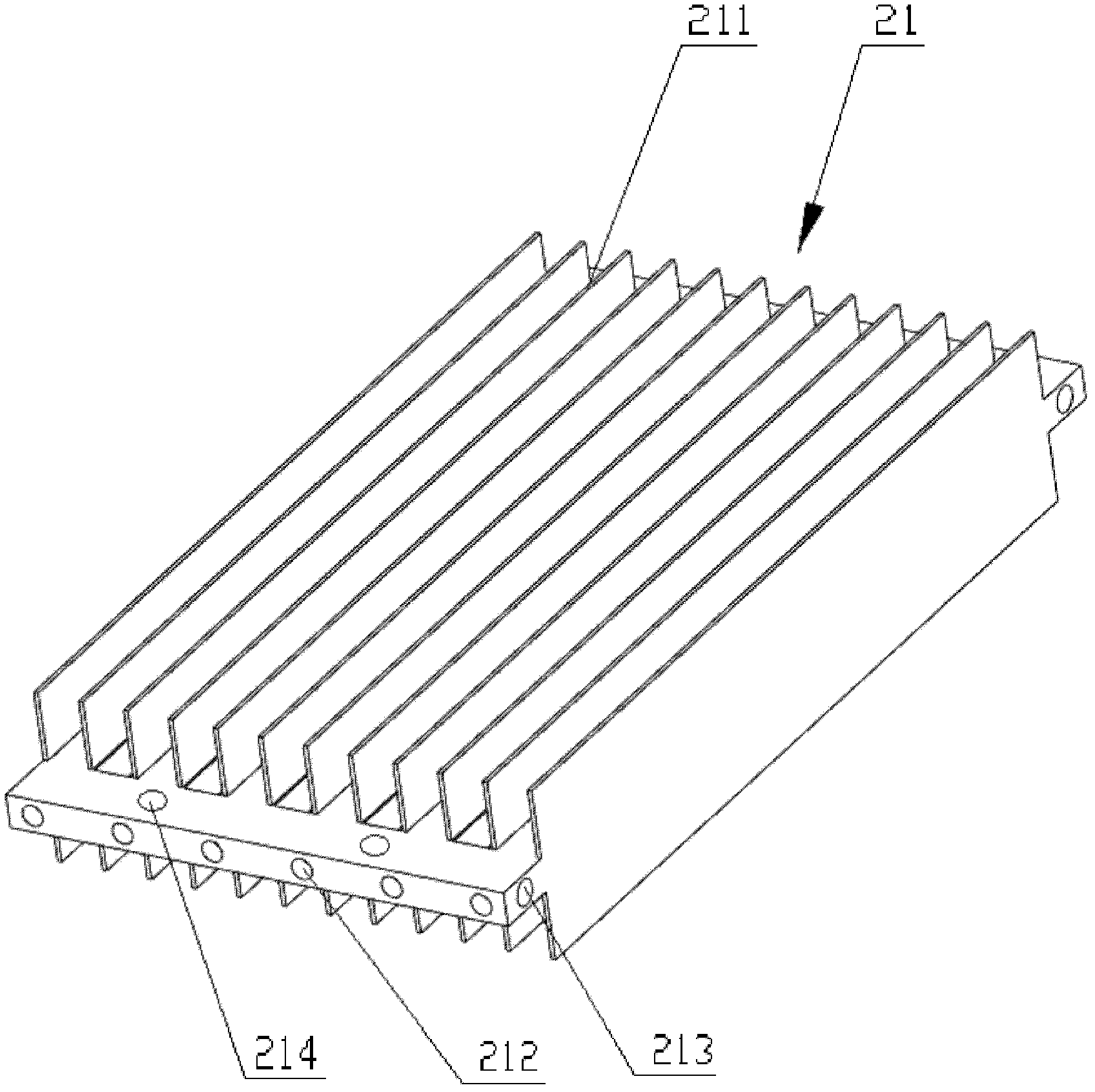

[0019] The core of the present invention is to provide a condenser in a gravity loop heat pipe radiator and a preparation method thereof. The preparation method of the condenser makes the longitudinal passage of the condenser and the transverse passage of the condenser an integral structure without welding. The working reliability of the condenser is high. Another core of the present invention is to provide a gravity loop heat pipe radiator and a preparation method thereof.

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For ease of understanding and brevity of discussion, the overall structure and preparation method of the condenser combined with the gravity loop heat pipe radiator will be described below, and the beneficial effects will not be discussed repeatedly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com