Rotating table type sandblasting machine

A sandblasting machine and desktop technology, applied in the field of sandblasting machines, can solve problems such as endangering the health of operators, reducing processing efficiency, and environmental pollution, and achieve the effects of high automation, high processing efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

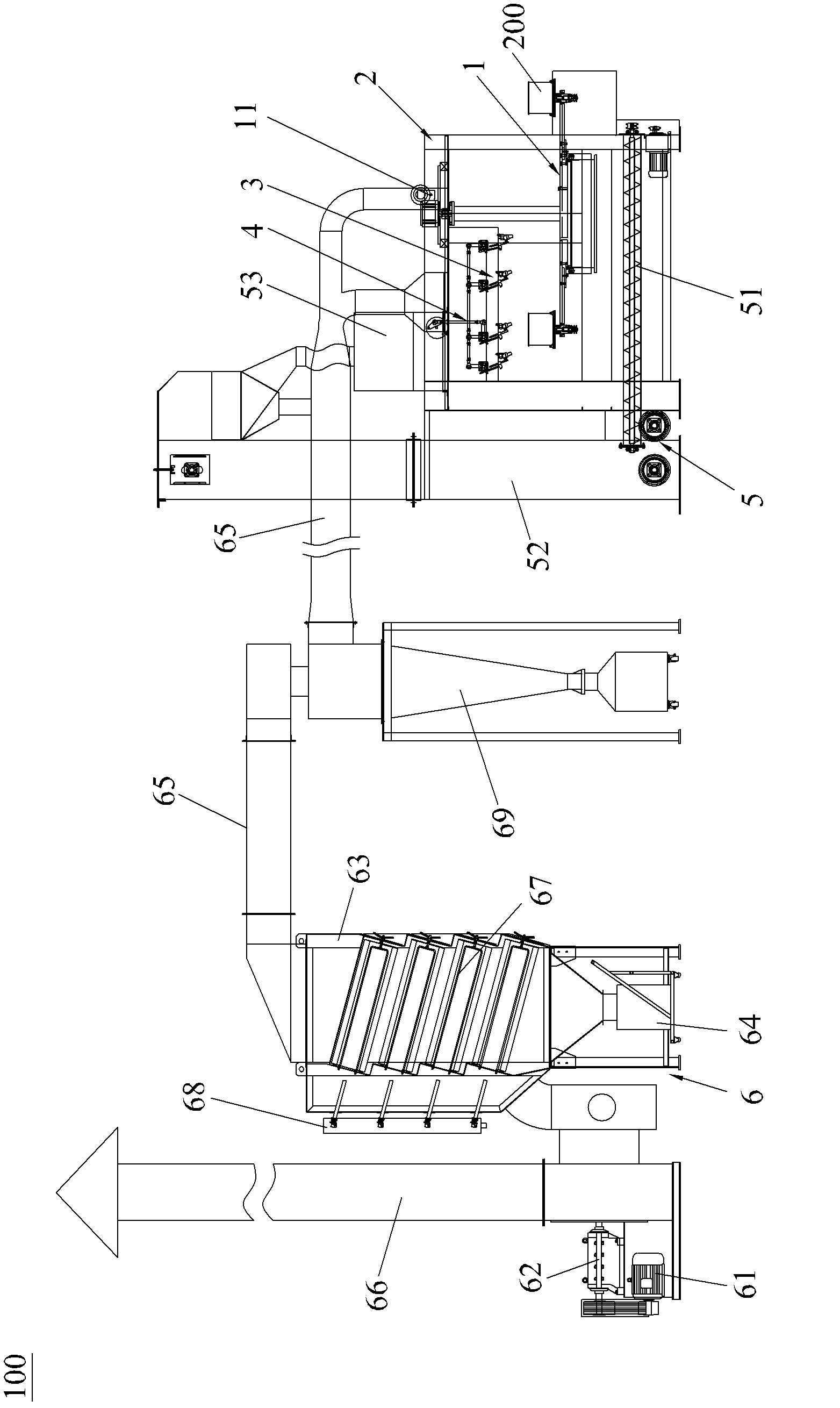

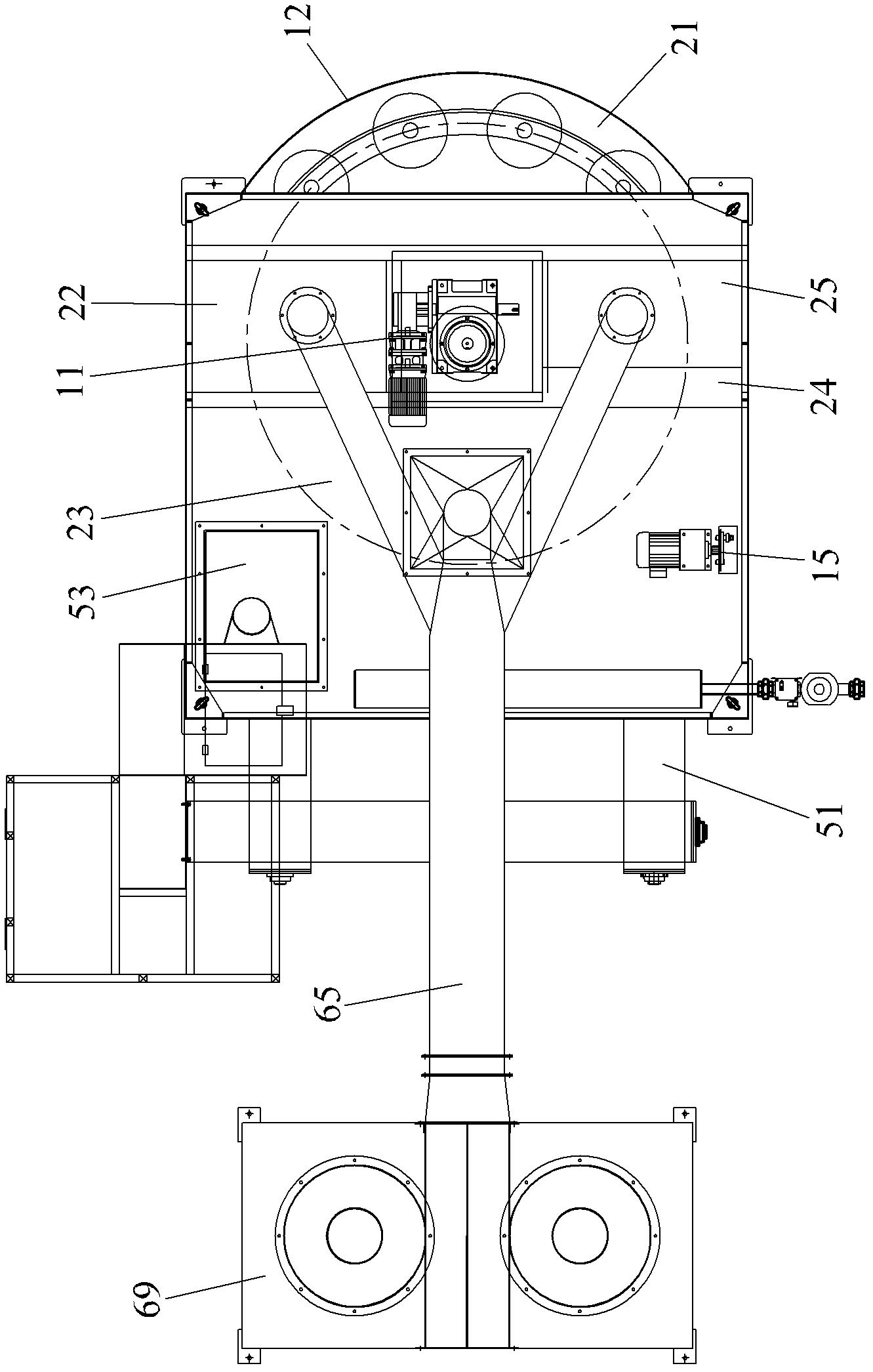

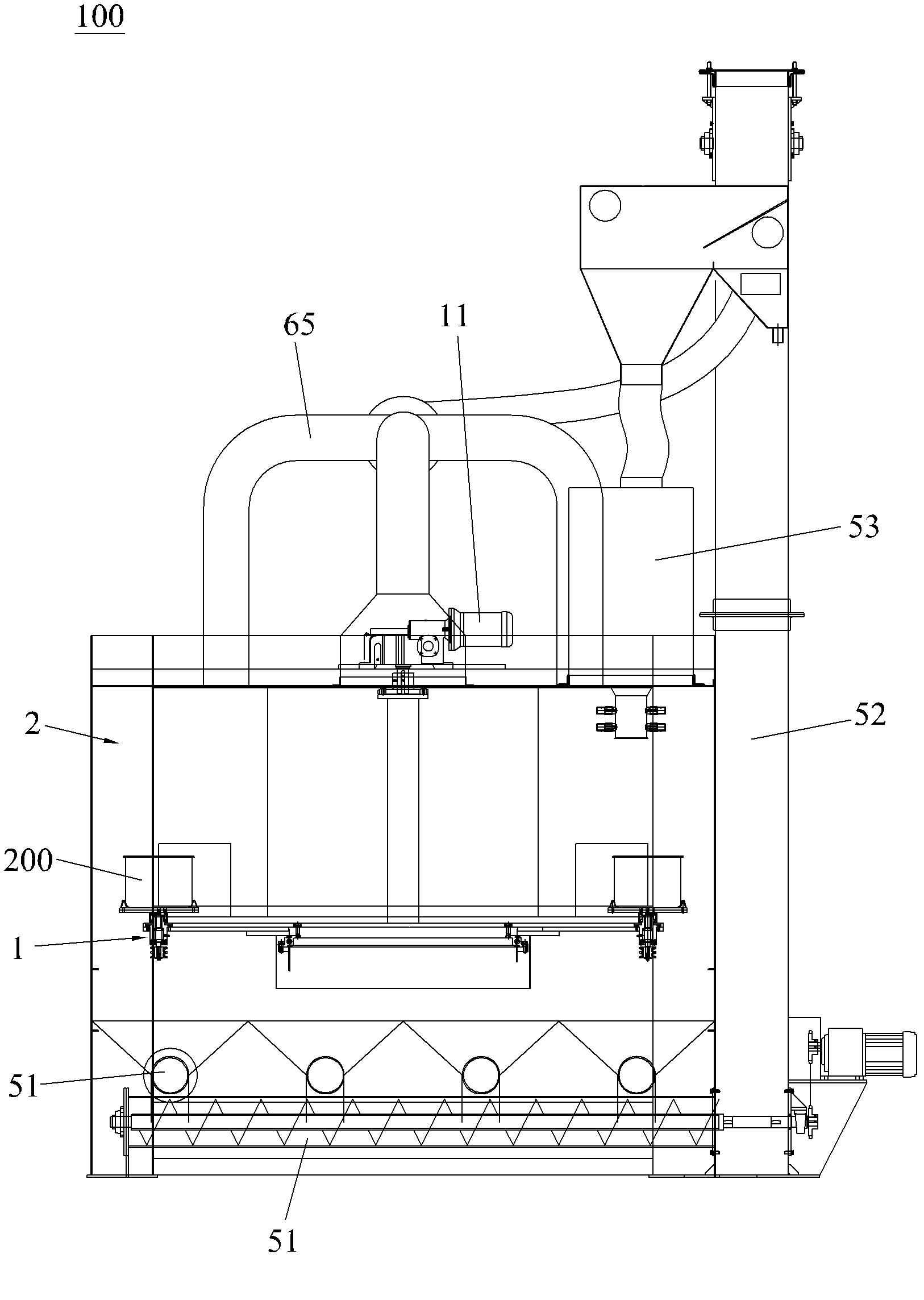

[0026] Such as figure 1 As shown, the rotary table sandblasting machine 100 of the present invention includes a rotary table conveying system 1, a working chamber 2, a plurality of spray guns 3, a plurality of groups of spray gun swing mechanisms 4, an abrasive recycling system 5, a dust removal system 6, and an air compression system (not shown in the figure). shown) and electronic control system (not shown in the figure).

[0027] to combine figure 2 , image 3 As shown, the turntable conveying system 1 is equipped with a sandblasting workpiece 200, and the sandblasting workpiece 200 rotates with the turntable conveying system 1; chamber 23 , a purge chamber 24 and a second isolation chamber 25 . During sandblasting, the turntable conveying system 1 drives the sandblasting workpiece 200 to pass through the upper and lower parts area 21, the first isolation chamber 22, the sandblasting chamber 23, the blowing room 24 and the second isolation chamber 25 in sequence; Spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com