Production line precast beam construction method

A construction method and technology of prefabricated beams, which are applied to manufacturing tools, ceramic molding machines, etc., can solve problems such as difficulty in taking thermal insulation and steam curing measures, inability to achieve factory-like operations in prefabricated areas, and unfavorable professional construction and management. The effect of reducing the interference of external unfavorable factors, being conducive to environmental protection and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

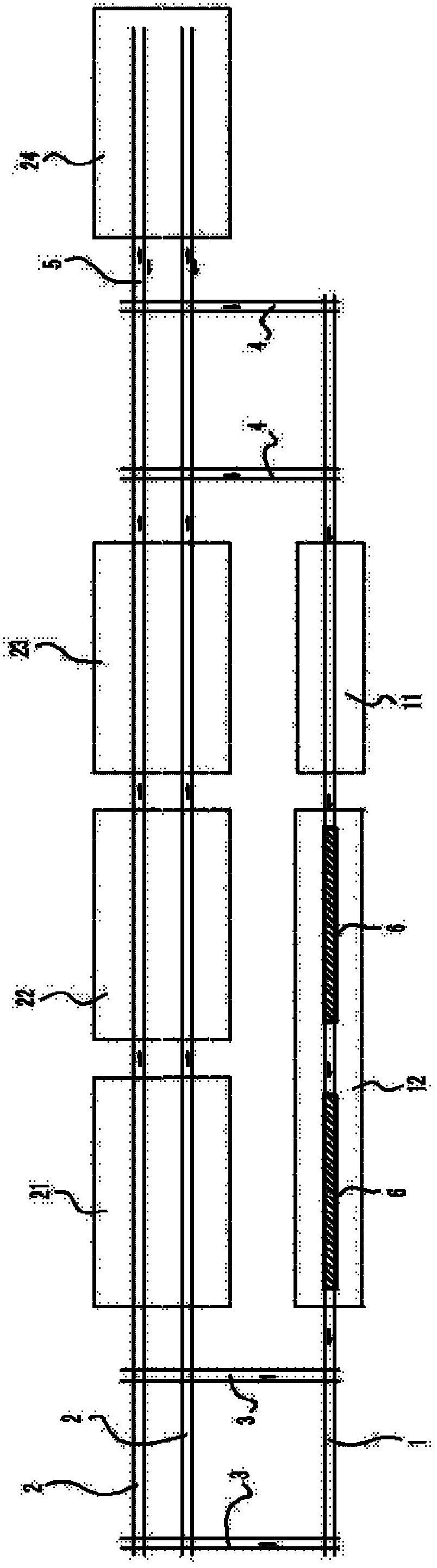

[0023] see figure 1 In this embodiment, the construction of the prefabricated beam on the assembly line is to divide the construction of the prefabricated beam into sections according to the process and finish it at each station arranged in different areas along the production line. It is fixedly arranged on the bottom form trolley, and the movement of the bottom form trolley among the stations along the production line forms the assembly line operation of the prefabricated beams following the bottom form trolley at each station.

[0024] Such as figure 1 As shown, the stations in different areas along the production line are: template cleaning station, steel bar installation station, concrete pouring station, concrete curing station and prestressing construction station.

[0025] The production line in this embodiment is set as a rectangular frame, and the template cleaning station 11 and the steel bar installation station 12 are arranged sequentially from right to left alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com