Method for producing forestry controlled-release fertilizer by utilizing sludge of urban sewage plant

A technology of urban sewage and controlled-release fertilizers, applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problems of low applicability of treatment equipment, low sludge treatment rate, long treatment time, etc. Achieve the effects of shortening fermentation time, wide application range and improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

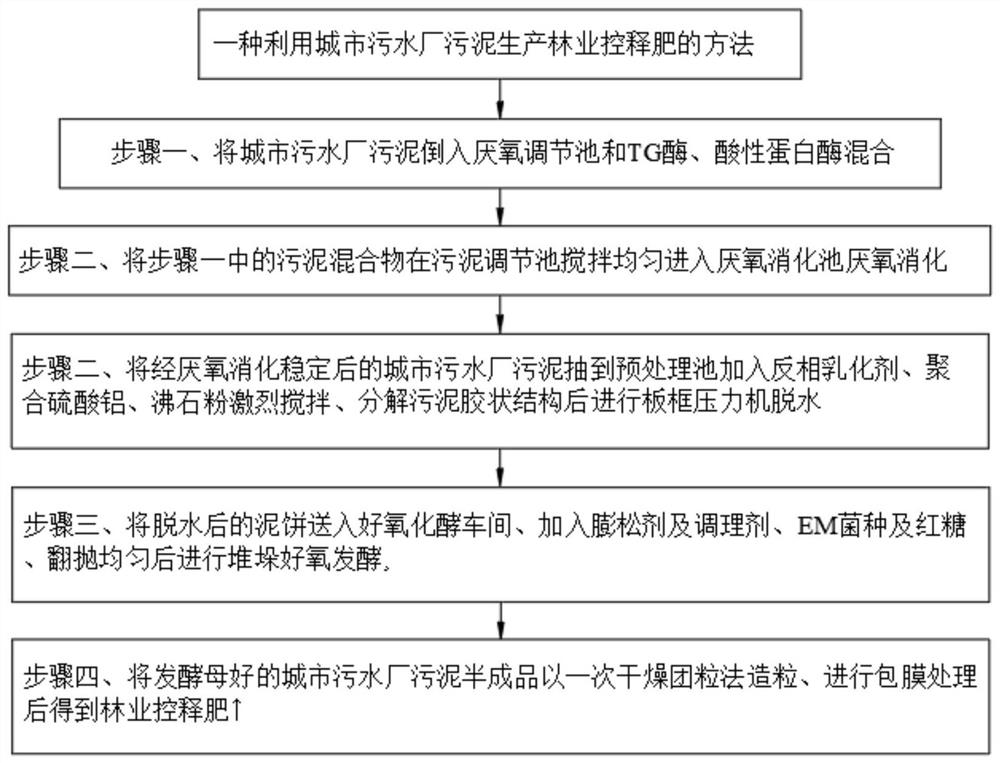

[0031] The present invention provides a technical scheme: a method for producing forestry controlled-release fertilizer by utilizing sludge from an urban sewage plant, comprising the following steps:

[0032] 1) Pour the municipal sewage plant sludge into the anaerobic regulation tank and mix it with TG enzyme and acid protease;

[0033] 2) The sludge mixture in step 1) is evenly stirred in the sludge conditioning tank and enters the anaerobic digestion tank for anaerobic digestion;

[0034] 3) Pumping the stabilized sludge from the anaerobic digestion to the pretreatment tank, adding inverse emulsifier, polyaluminum sulfate, and zeolite powder, stirring vigorously to decompose the colloidal structure of the sludge, and then dewatering by a plate-and-frame press;

[0035] 4) Send the dehydrated mud cake to the aerobic fermentation workshop, add leavening agent and conditioning agent, EM strain and brown sugar, and then perform stacking aerobic fermentation after turning evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com