Automatic separating and combining track type paperboard integrated forming machine

A track-type, forming machine technology, applied in the direction of paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of low production efficiency and low degree of automation, and achieve high production efficiency, high degree of automation and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

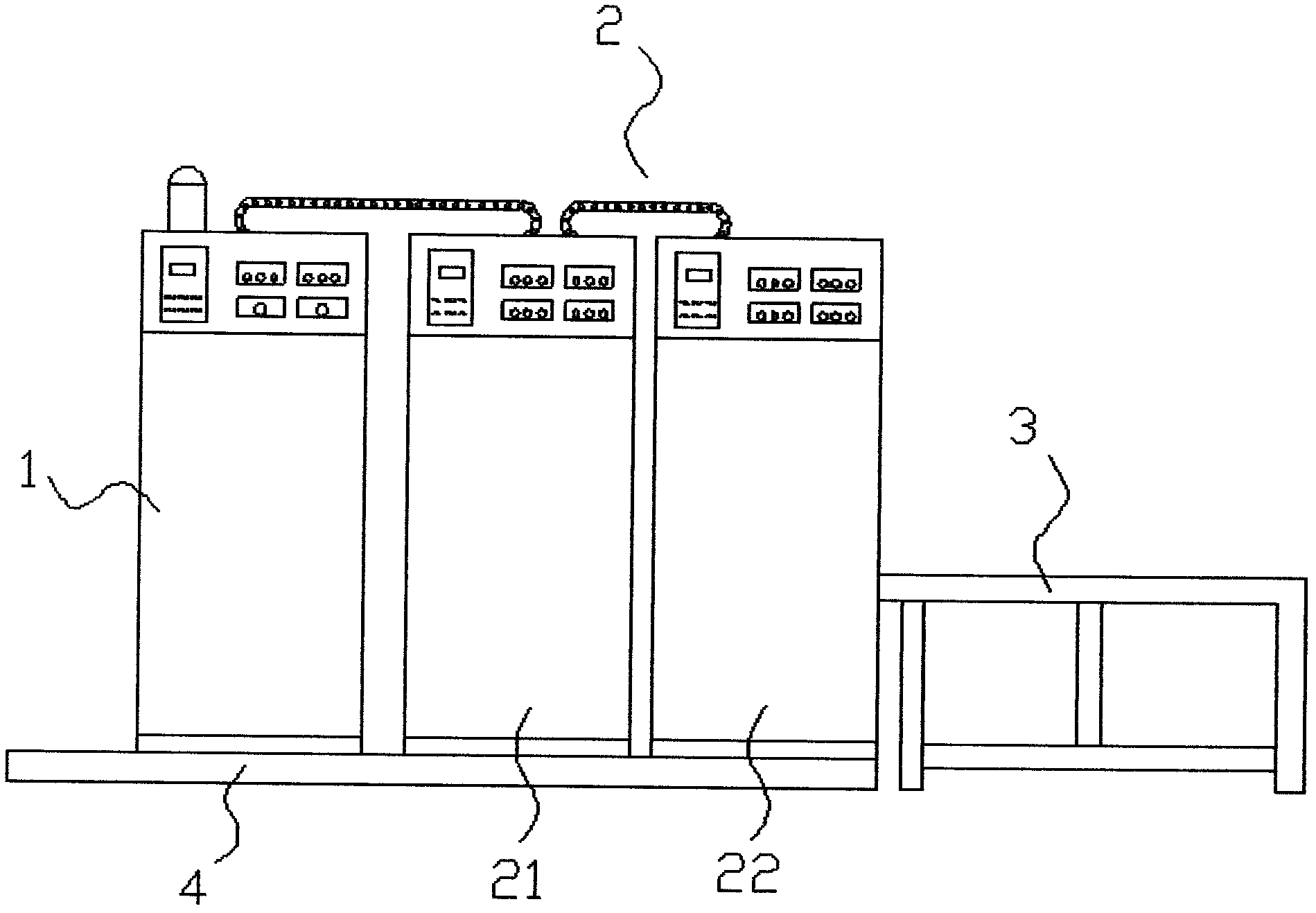

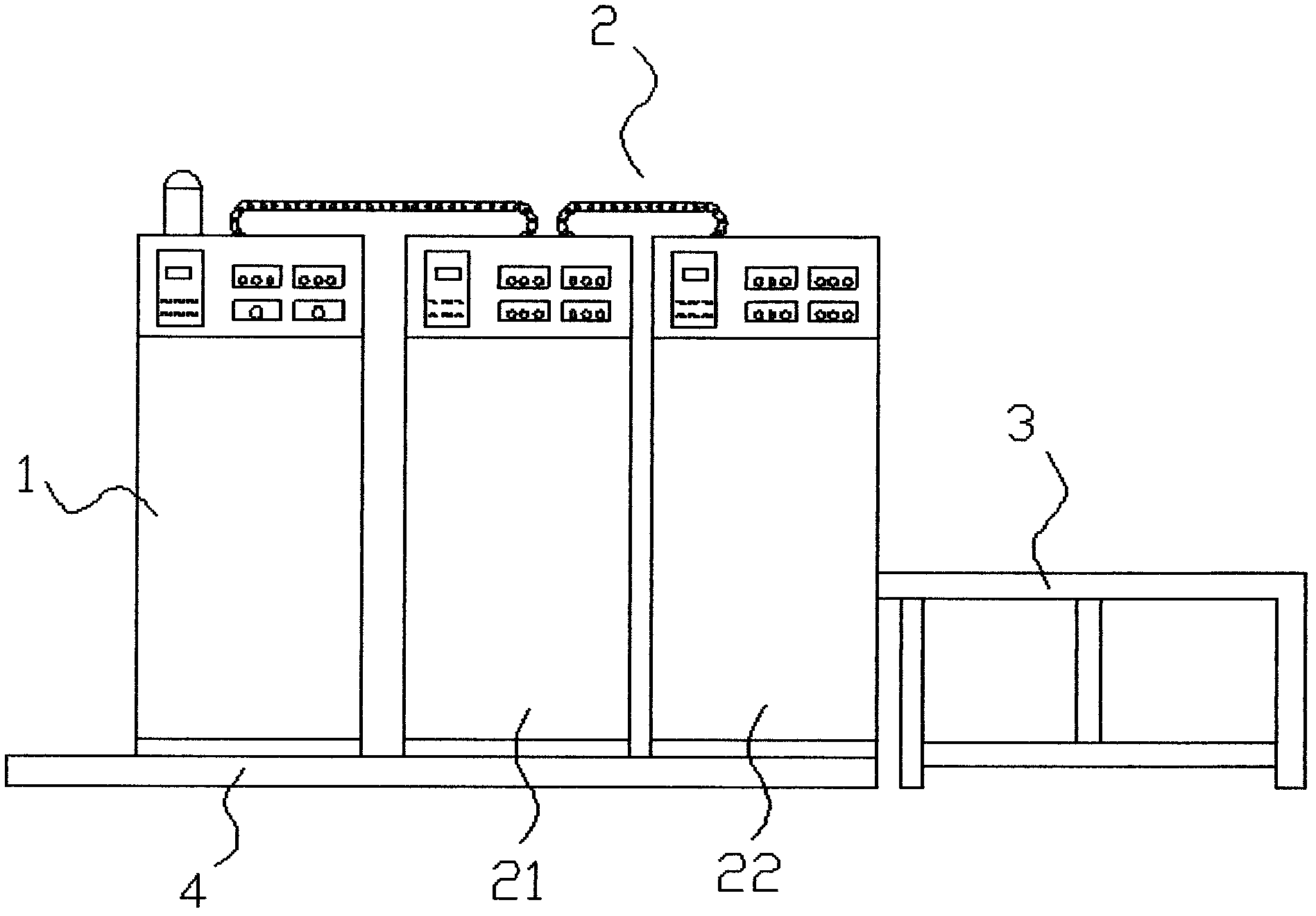

[0012] Such as figure 1 As shown, an automatic separation and closing rail-type cardboard integrated molding machine includes a paper feeding table 3, a printing unit 2 and a roller line paper cutting corner slotting group 1, and the printing unit 2 is arranged on the paper feeding table 3 and the roller. Between the line separation paper cutting angle slotting group 1, the printing unit 2 and the roll line separation paper cutting angle slotting group 1 are arranged on the track 4, and the printing unit 2 includes the first plate printing group 22 and the second plate printing group 21. There is a separate combined structure between the rolling line separation cutting corner slotting group 1, the first printing group 22 and the second printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com