Equipment for producing full-automatic high-speed cellular board

A technology for producing equipment and honeycomb panels, applied in the direction of cardboard items, etc., can solve the problems of wasting raw materials, maximizing the length of the product strength and stretching, and not being able to apply glue evenly, so as to facilitate use and maintenance, and avoid glue materials. The effect of spillover and avoiding cross-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The design points of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

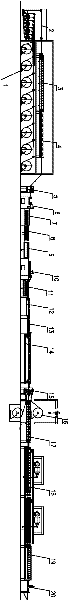

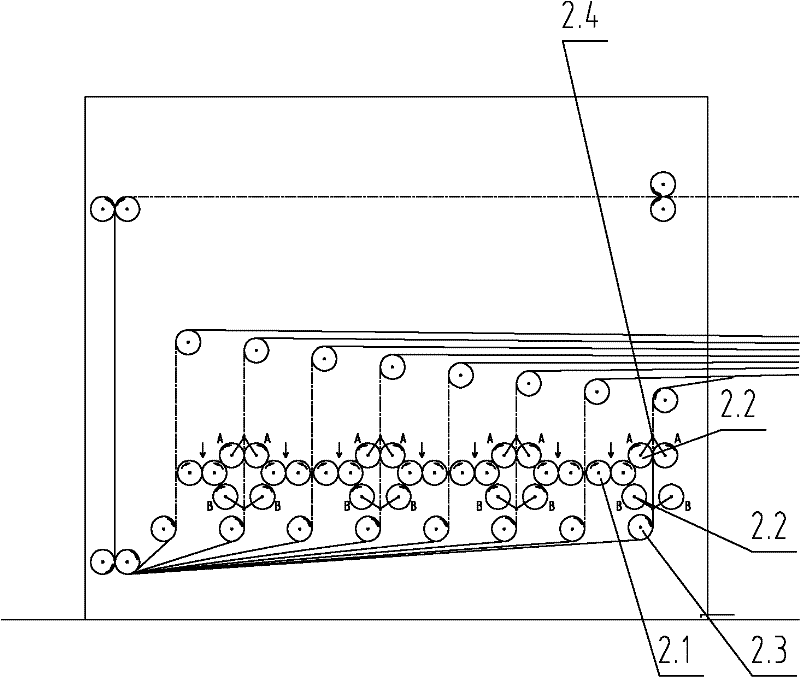

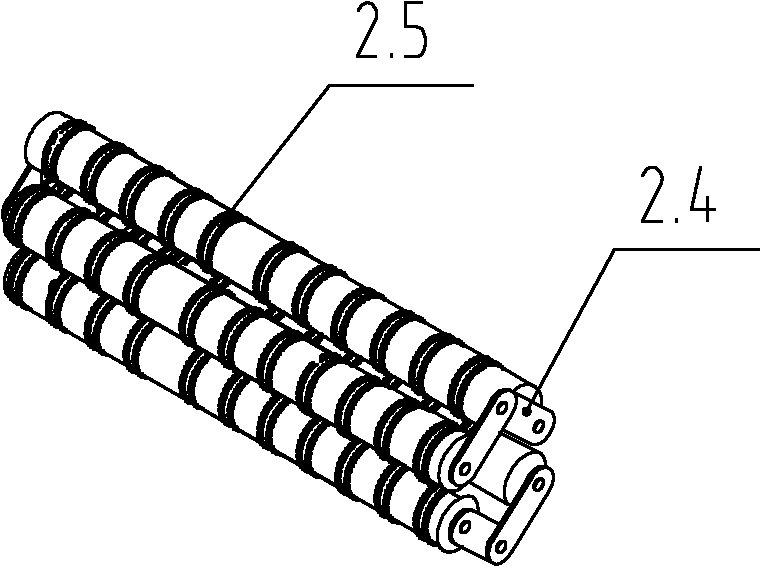

[0055] Such as figure 1 As shown, a fully automatic high-speed honeycomb panel production equipment includes a coil machine 1 that transports the glued core material to a conveying compactor 3; coats the surface of the core material with an adhesive tape at a predetermined distance Comprehensive gluing machine 2; compacting and bonding several layers of gluing core material into a core and transporting it to the next process conveying compactor 3; core drying machine 4 for drying the core ; Secondary gluing machine 5 for secondary gluing on the upper surface of the board core; Cross cutting machine 6 for cutting the board core into a predetermined size; Laminating machine for stacking board cores of a predetermined size up and down 7 A compacting machine 8 for core compaction and bonding; a lifting platform 9 for lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com