Laser marking method and device adopting same

A laser marking and laser engraving technology, which is applied in the field of laser marking, can solve problems such as difficult to identify codes and the processing range cannot cover the full length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

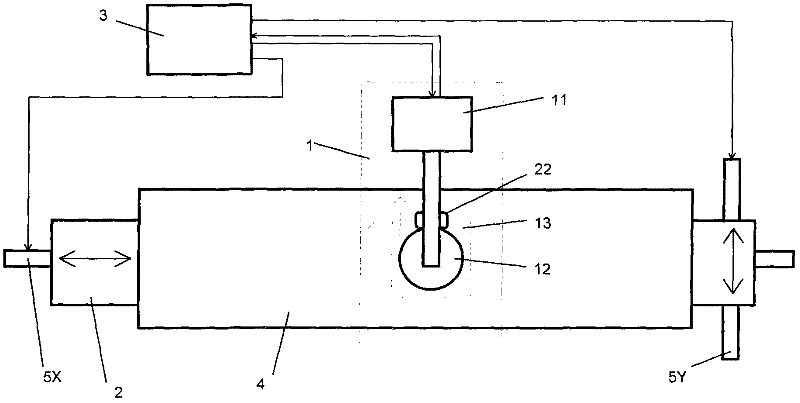

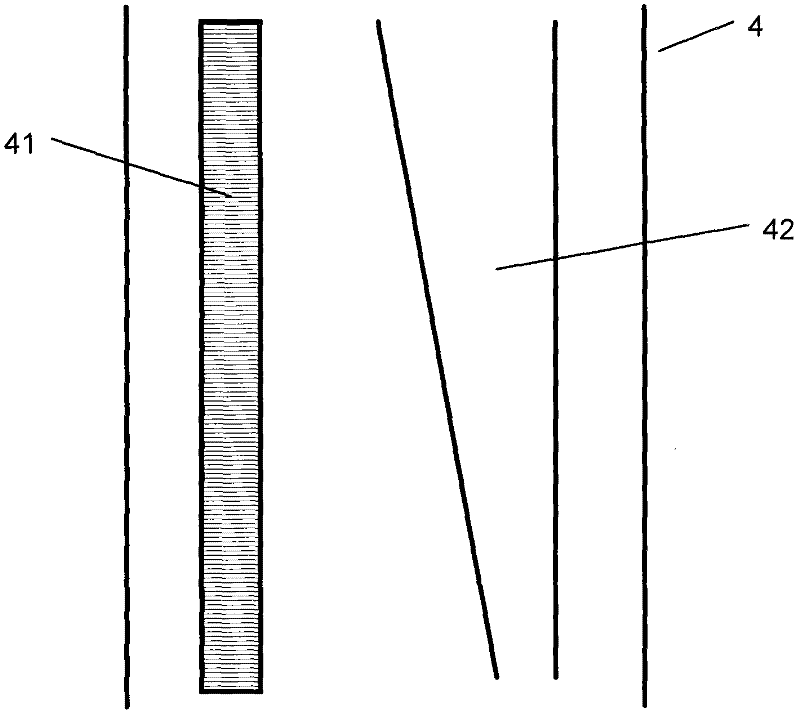

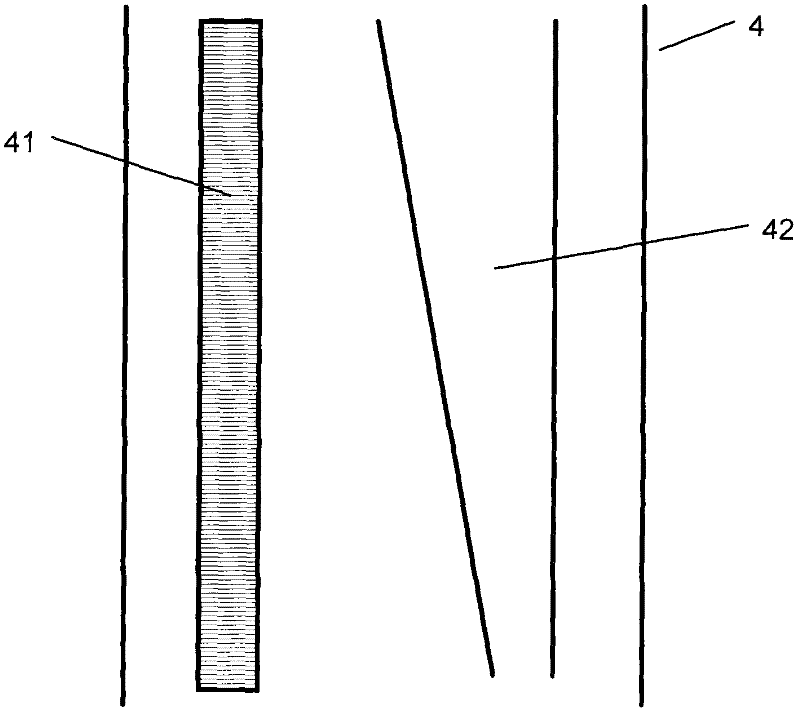

[0008] according to figure 1 A marking device according to the invention for the production of long semiconductor columns for photovoltaic cells comprises a laser inscription device 1 with a laser source 11 whose radiation emission takes place via a scanner 12 and an objective lens (not shown). The laser inscription device 1 is connected to a control computer 3 which is connected on the entry side to a detection system 22 for the actual coordinate values. The detection system 22 for the actual coordinate values is arranged next to the scanner 12, but could instead be arranged at any other suitable point. The control signal of the computer 3 is put into the scanner 12, so that radiation guidance is performed inside the engraving range 13. Radiation guidance is performed in a known manner by shifting the scanner level. The introduction of the semiconductor column 4 takes place by means of a transport device 2 which can be positioned in two dimensions by means of two drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com