Self-discharging car for inclined shaft

A self-unloading and mining car technology, which is applied in the direction of freight cars, transport passenger cars, railway car body parts, etc., can solve the problem of reducing the stress load of the axle body, reduce the stress load, improve construction production efficiency, and have high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

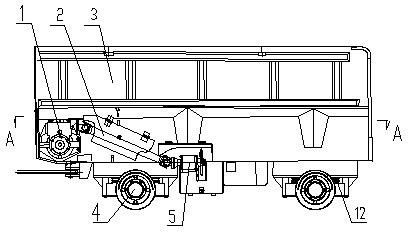

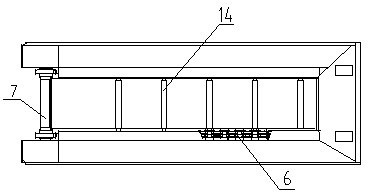

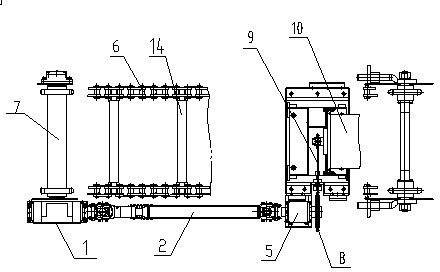

[0012] exist figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Among them, the inclined shaft self-unloading mine car includes a car body 3 and an axle body 4, the car body is a steel structure, and the axle body includes a main shaft 15 and wheels matched with the two ends of the main shaft, and the axle body A buffer spring 13 is arranged in the middle of the main shaft 15 on the top, and a scraper conveyor is arranged between the car body and the axle body, and the scraper conveyor includes a chain transmission shaft 7, a conveying chain 6, a scraper 14 and a universal drive Shaft 2, the chain drive shaft 7 is connected to the conveying chain 6 through a sprocket (not shown in the figure), and scrapers 14 are arranged at intervals on the conveying chain, and one end of the chain drive shaft is connected to the worm gear reducer 1 to convey The chain spans the chain drive wheel and the driven wheel (not shown in the figure), the worm gear reducer is arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com