Gap-type automatic opening-and-closing delivery magnetic clamp

An automatic opening and closing, gap-type technology, used in transportation and packaging, object supply, pile separation, etc., can solve problems such as damage, and achieve the effect of extending service life, stable clamping and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

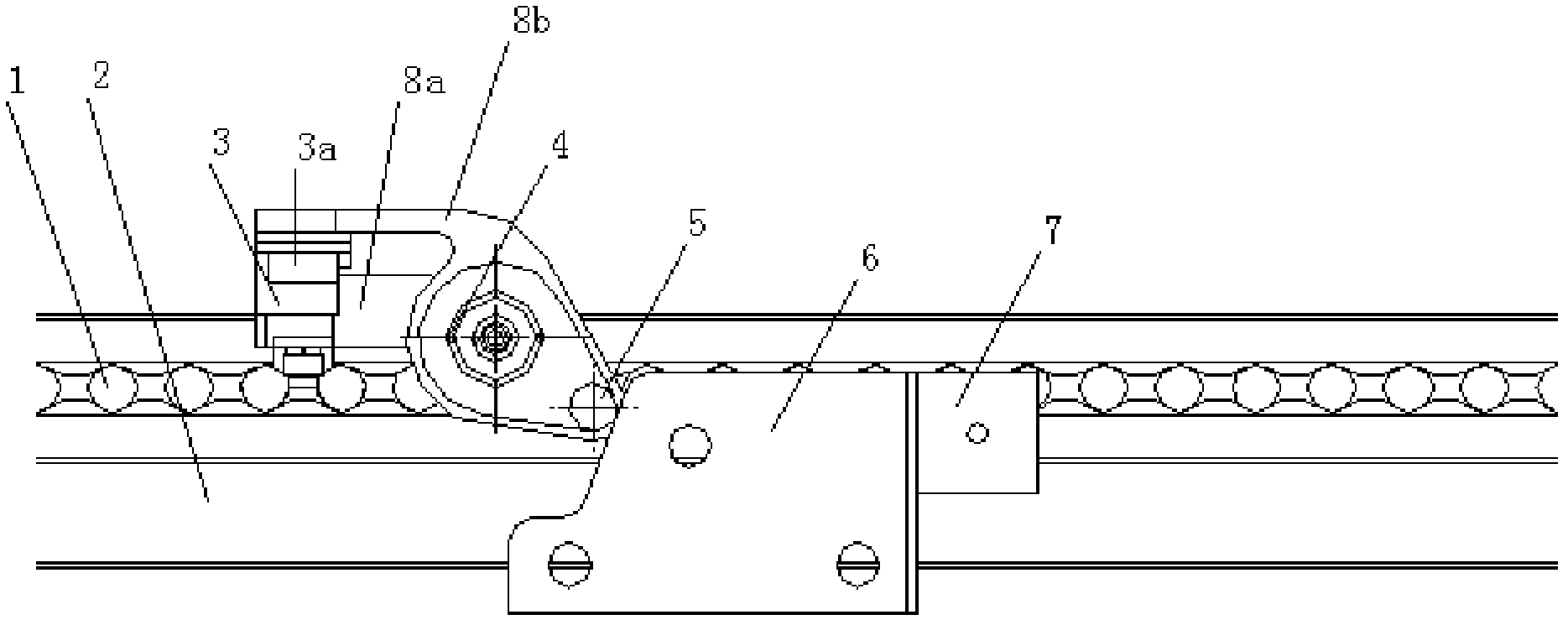

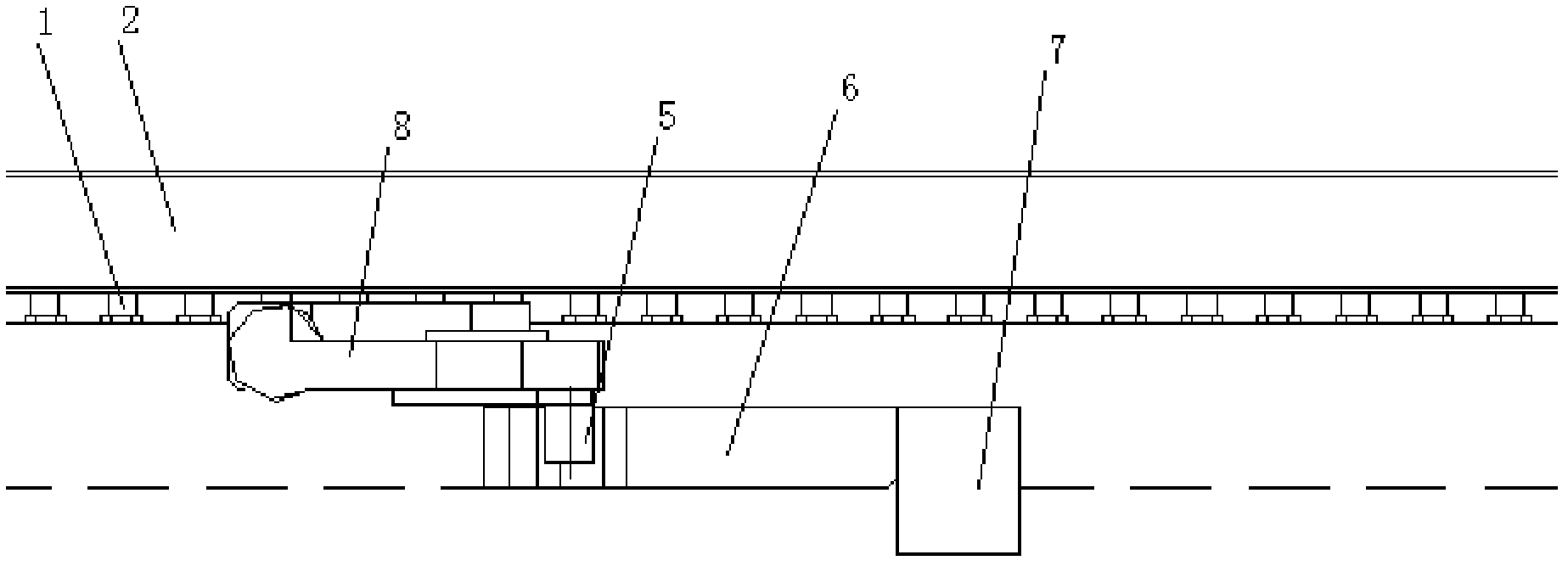

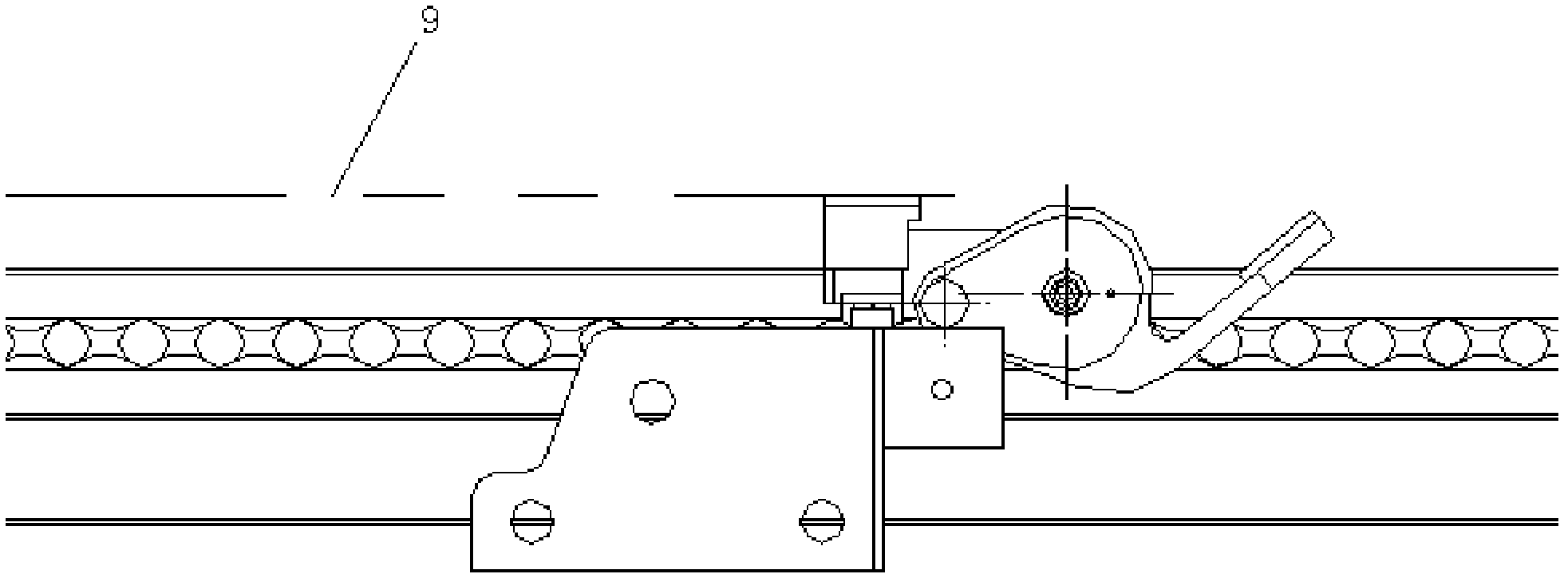

[0024] Such as figure 1 , figure 2 As shown, the gap-type automatic opening and closing conveying magnetic clamp includes a guide seat 2, a pulling part 1, a clamping mechanism 8 and an opening and closing part 6. The pulling part 1 is movably arranged on the guide seat 2, and the guide seat 2 serves as a pulling The guide piece of the pulling part 1, the opening and closing part 6 is fixed on the side of the guide seat 2, and the clamping mechanism 8 is fixed on the pulling part 1; the clamping mechanism 8 includes a fixed part 8a and a movable part 8b, the fixed part 8a and the movable part The parts 8b are movably connected, and between the fixed part 8a and the movable part 8b, an elastic member 4 capable of closing the fixed part 8a and the movable part 8b is provided; one end of the movable part 8b is provided with a guide part 5, the guide The part 5 is placed on the side of the opening and closing part 6 .

[0025] When working, the pulling part 1 pulls the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com