Alginate filler strip and preparation method and application thereof

An alginate and filling strip technology, applied in the field of medical materials, can solve the problems of difficulty in filling, infection, limited absorption, etc., and achieve the effects of improving relative moisture retention, promoting absorption capacity, and good ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

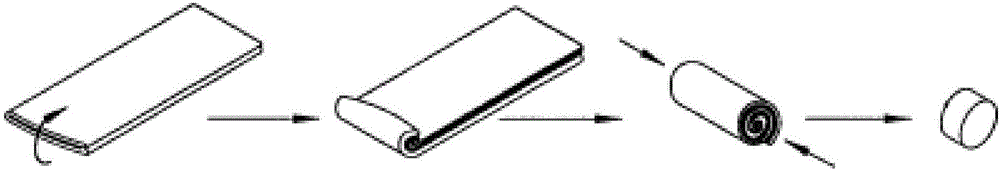

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of alginate filling strip according to the present invention

[0037] Dissolve sodium alginate in a solution using a mixed solution of purified water and ethanol (1:1 by mass percentage) as a solvent, add sodium carboxymethyl cellulose, stir well, and make sodium carboxymethyl cellulose with a mass percentage of 1.2%, 4% alginate solution by mass percentage of alginate; prepare 10% pectin aqueous solution by mass percentage.

[0038] Mix the above-mentioned pectin aqueous solution and alginate solution at a volume ratio of 1.5:10, stir the mixed solution vigorously until it forms a homogeneous system, and use it as an alginate spinning stock solution, and place it in an additional circle between the microinjector and the patterned electrode. ring patterned electrode electrospinning device in a microinjector;

[0039] At a temperature of 25°C and a humidity of 45%, adjust the microinjector to 0.1-0.12ml / h, adjust the ring voltage to 4.5KV, adju...

Embodiment 2

[0043] Example 2: Tests on water absorption, gelation properties and dispersion properties of different filling strips

[0044] 1. Test object

[0045] Group 1: Filling strips according to Embodiment 1 of the present invention;

[0046] Group 2: Other commercially available alginate filling strips (strip dressings made of other alginate fibers through wet spinning, in line with the third category of medical devices exempted from clinical trials announced by the State Food and Drug Administration Catalog and pharmaceutical industry standard YY / T 1293.5-2017 "Contact Wound Dressing Part 5: Alginate Dressing" requirements);

[0047]The 3rd group: use the raw material in the embodiment 1 of the present invention, according to the filling strip prepared by wet spinning process;

[0048] Group 4: Filling strips prepared according to the method described in Example 1 of patent CN103060946A;

[0049] 2. Results

[0050] The above 4 groups of objects were tested for water absorptio...

Embodiment 3

[0054] Embodiment 3: Moisture retention test of different filling strips

[0055] With reference to the test object of embodiment 2 and add cotton gauze test object (cotton gauze is the 5th group), cut each group of samples (2 ± 0.1) g respectively, after each sample is tiled respectively in the petri dish that diameter is 100mm and keep the sample flat; use a dropper to evenly drop simulated body fluid 5 times the mass of each sample on the surface of the sample, and then weigh it immediately; place each petri dish at 37°C and humidity of (60±15)%. Leave it on, weigh every 1d, and evaluate the moisture retention performance of each sample. The test results are shown in Table 2.

[0056] Moisture retention rate = (initial mass - weighed mass) / water mass in simulated body fluid x 100%

[0057] Table 2

[0058]

[0059] It can be seen from the data in Table 2 that although the moisture retention rate of each group gradually decreases over time, the moisture retent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com