Waste lubricating oil regeneration coagulation sedimentation composite equipment

A technology of waste lubricating oil, coagulation and sedimentation, applied in the direction of lubricating composition, etc., can solve the problems of complex equipment, difficult cleaning operation, long sedimentation time, etc., and achieves low equipment investment and operating costs, simple process flow, and overall compact equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

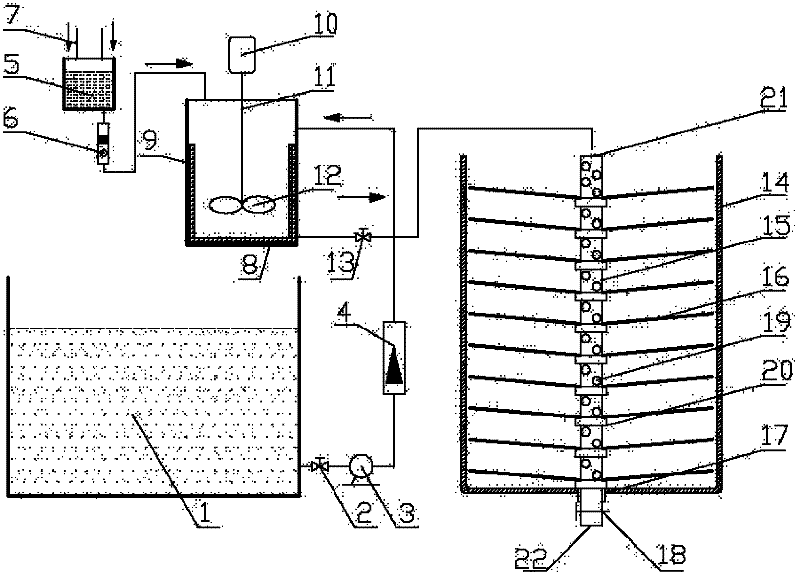

[0036] The waste lubricating oil regenerating coagulation and sedimentation composite equipment is characterized in that it includes a waste lubricating oil feeding unit, a flocculant adding unit, a stirring device and a settling device.

[0037] The waste lubricating oil inlet unit and the flocculant adding unit are connected to the stirring device at the same time; the stirring device is connected to the settling device.

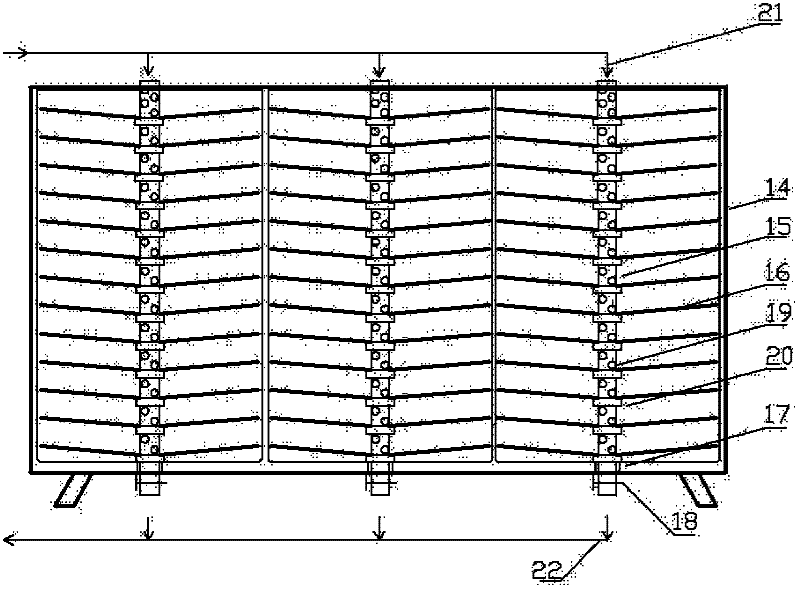

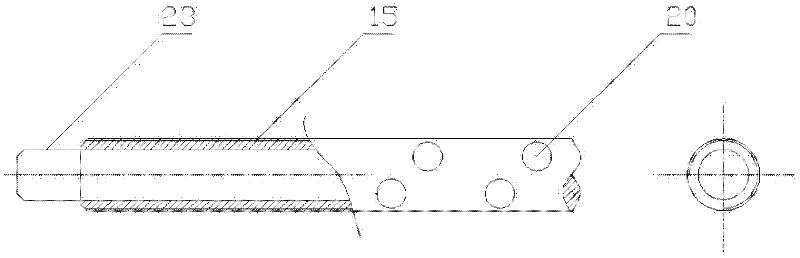

[0038] The settling device includes a settling tank, a center pipe, and a ring-shaped settling plate.

[0039] There is a round hole at the center of the bottom of the settling tank, and a center pipe is inserted into the round hole;

[0040] The center pipe is a hollow pipe with the same diameter as the center hole at the bottom of the settling tank. The center pipe 15 protrudes a certain distance from the bottom of the settling tank, and the bottom end of the center pipe is equipped with a valve;

[0041] The equipment is also equipped with an independe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com