Graphite crucible for growing large-size silicon carbide single crystal by physical vapor deposition method and application thereof

A technology of physical vapor deposition and silicon carbide single crystal, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as the difficulty of growing silicon carbide single crystal materials, achieve convexity reduction, reduce production costs, crystal The effect of improving the type stability rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

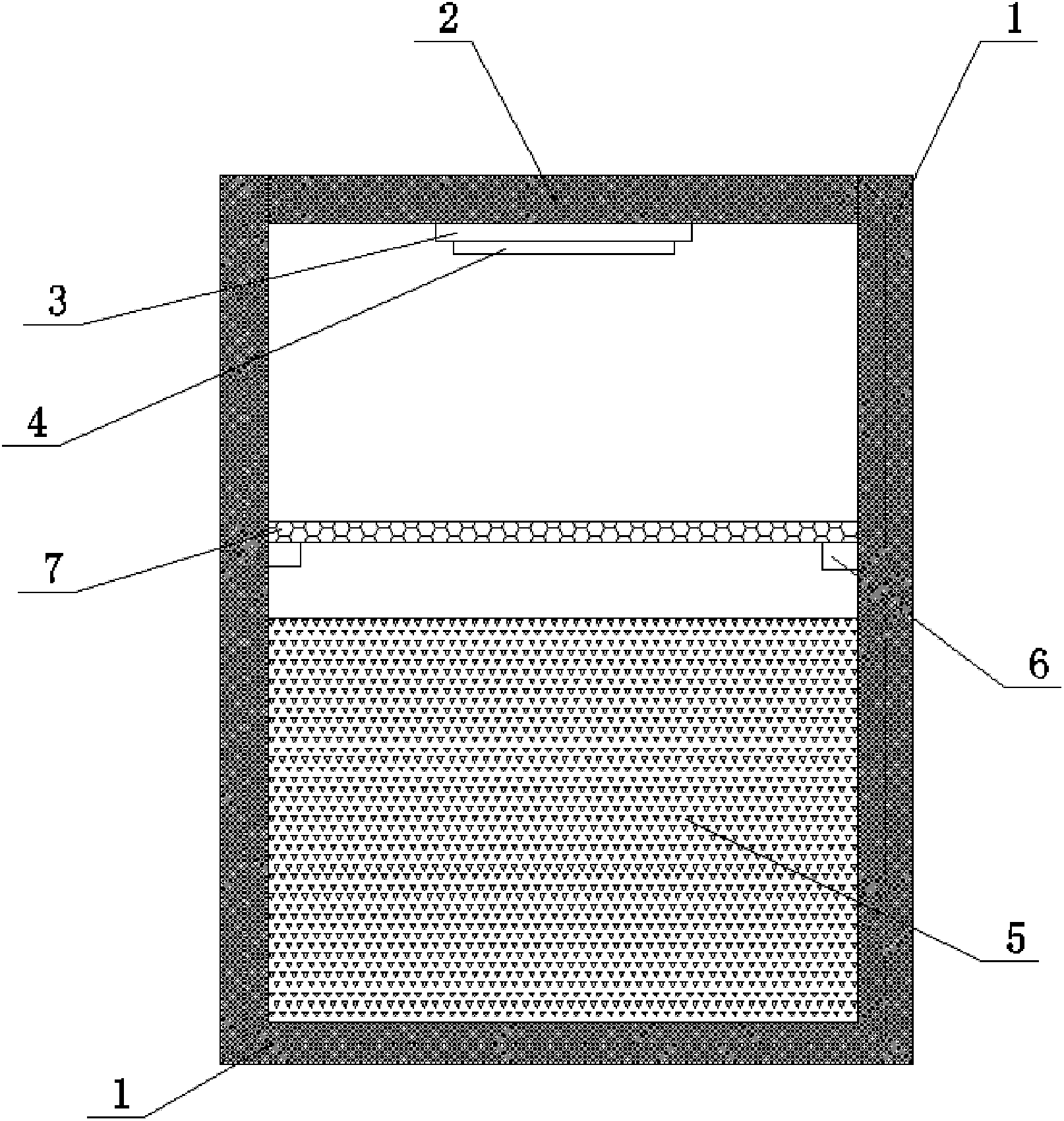

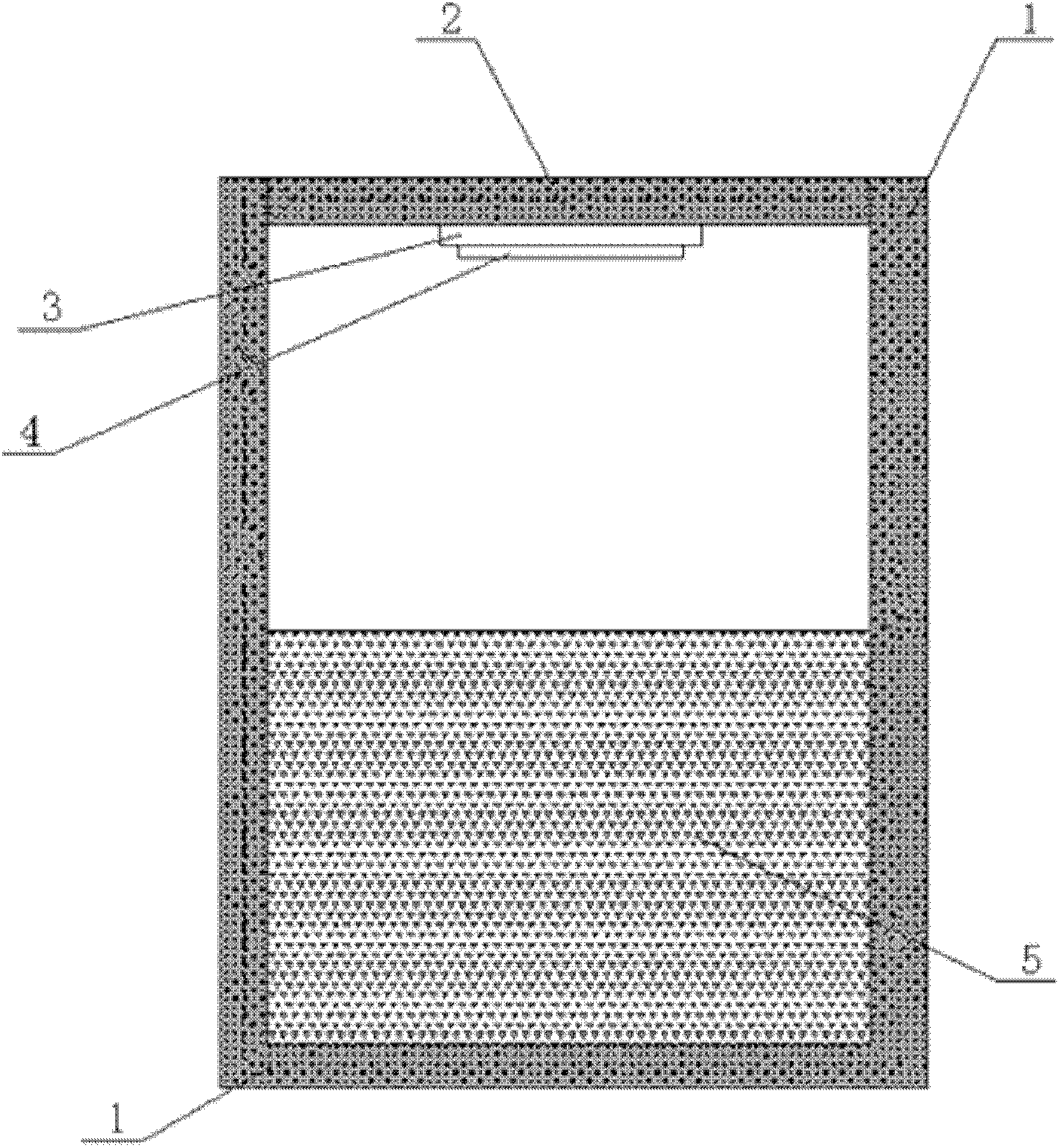

[0030] Such as figure 1 shown. A graphite crucible for growing large-size silicon carbide single crystals by physical vapor deposition, comprising a crucible barrel 1 and an upper cover 2 for containing silicon carbide raw materials, and an upper inner wall of the crucible barrel 1 and an outer wall of the upper cover 2. screw thread, the upper cover 2 and the crucible barrel 1 are connected by threads; the inner wall of the crucible barrel 1 is provided with a positioning block 6 for placing a porous graphite plate, and the positioning block 6 is along the inner wall of the crucible barrel for a week Set in a circular shape; a porous graphite plate 7 is placed on the positioning block 6, and the outer diameter of the porous graphite plate 7 should adapt to the inner diameter of the crucible barrel 1; the material of the crucible barrel 1 and the upper cover 2 is high Density graphite, the density of described high-density graphite is: 1.6g / cm 3 . The material of described ...

Embodiment 2

[0032] A method for producing silicon carbide single crystals using the graphite crucible described in Example 1, comprising adding silicon carbide raw materials into the crucible barrel 1, the distance between the upper surface of the silicon carbide raw material and the lower surface of the porous graphite plate 7 The thickness is 10mm; the seed crystal base and the seed crystal are arranged on the lower surface of the upper cover, the upper cover is connected to the crucible barrel through threads and covered, and a silicon carbide single crystal is prepared by physical vapor deposition. The physical vapor deposition method for preparing silicon carbide single crystals is a prior art.

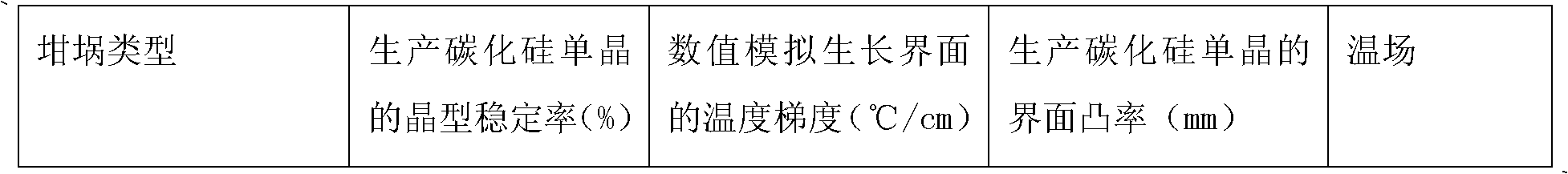

[0033] Using the graphite crucible described in Example 1 and the method described in Example 2, 50 furnaces of 3-inch 4H-SiC single crystals were grown. The results are listed in Table 1.

Embodiment 3

[0034] Embodiment 3, the graphite crucible as described in embodiment 1, its difference is:

[0035] The positioning block 6 includes a plurality of raised blocks arranged along the inner wall of the crucible barrel; the density of the high-density graphite is 1.7g / cm 3 . The density of described low-density porous graphite is 0.5g / cm 3 , the porosity range of the porous graphite plate is 60%; the thickness of the porous graphite plate is 15mm. The inner diameter of the crucible barrel is 200mm; the height of the crucible barrel is 450mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com