Shearing device for embroidery machine

A machine thread trimming and embroidery machine technology, which is applied in the field of embroidery machine thread trimming devices, can solve the problems of thread hooking, product quality decline, and thread not being hooked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

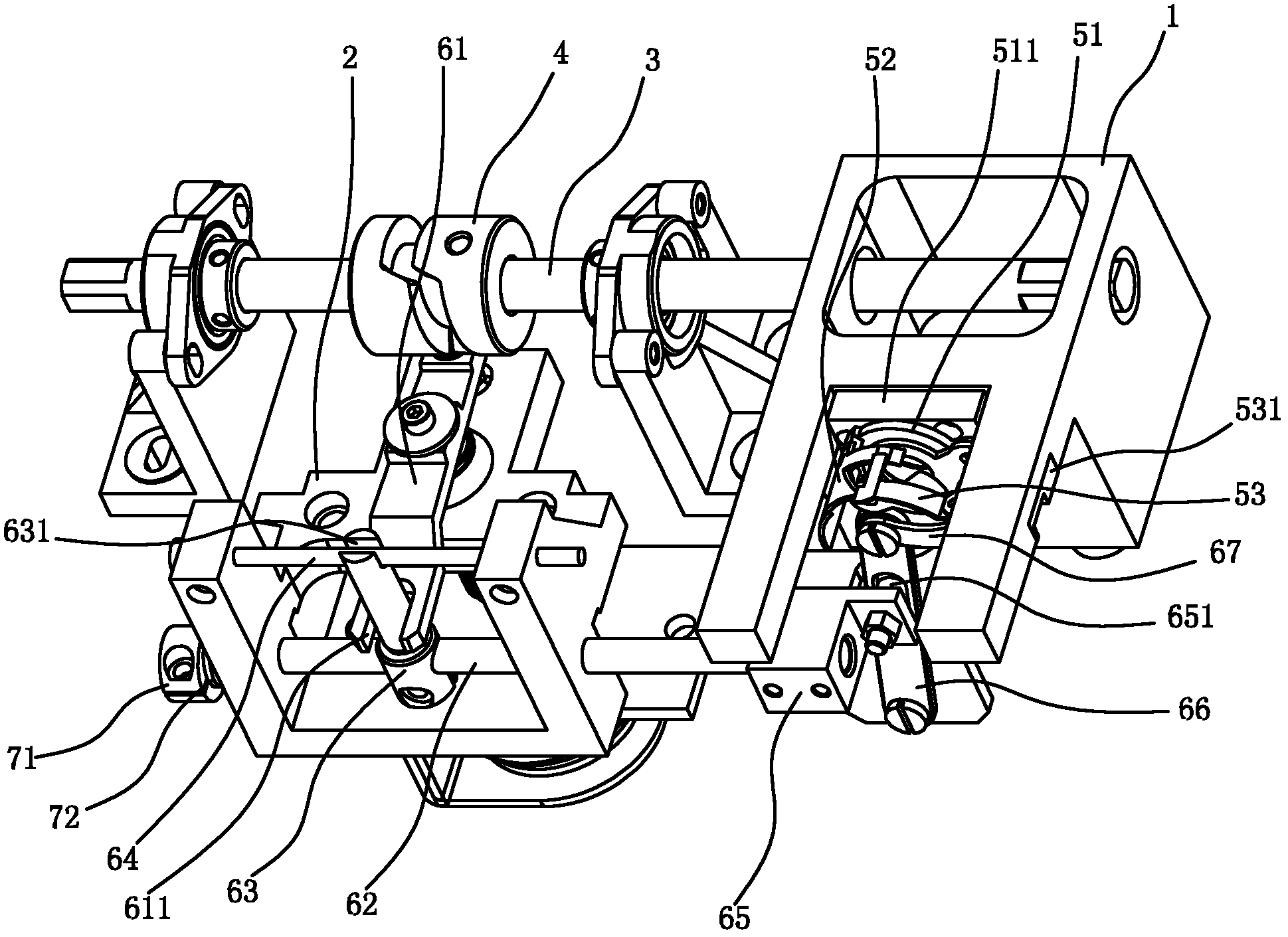

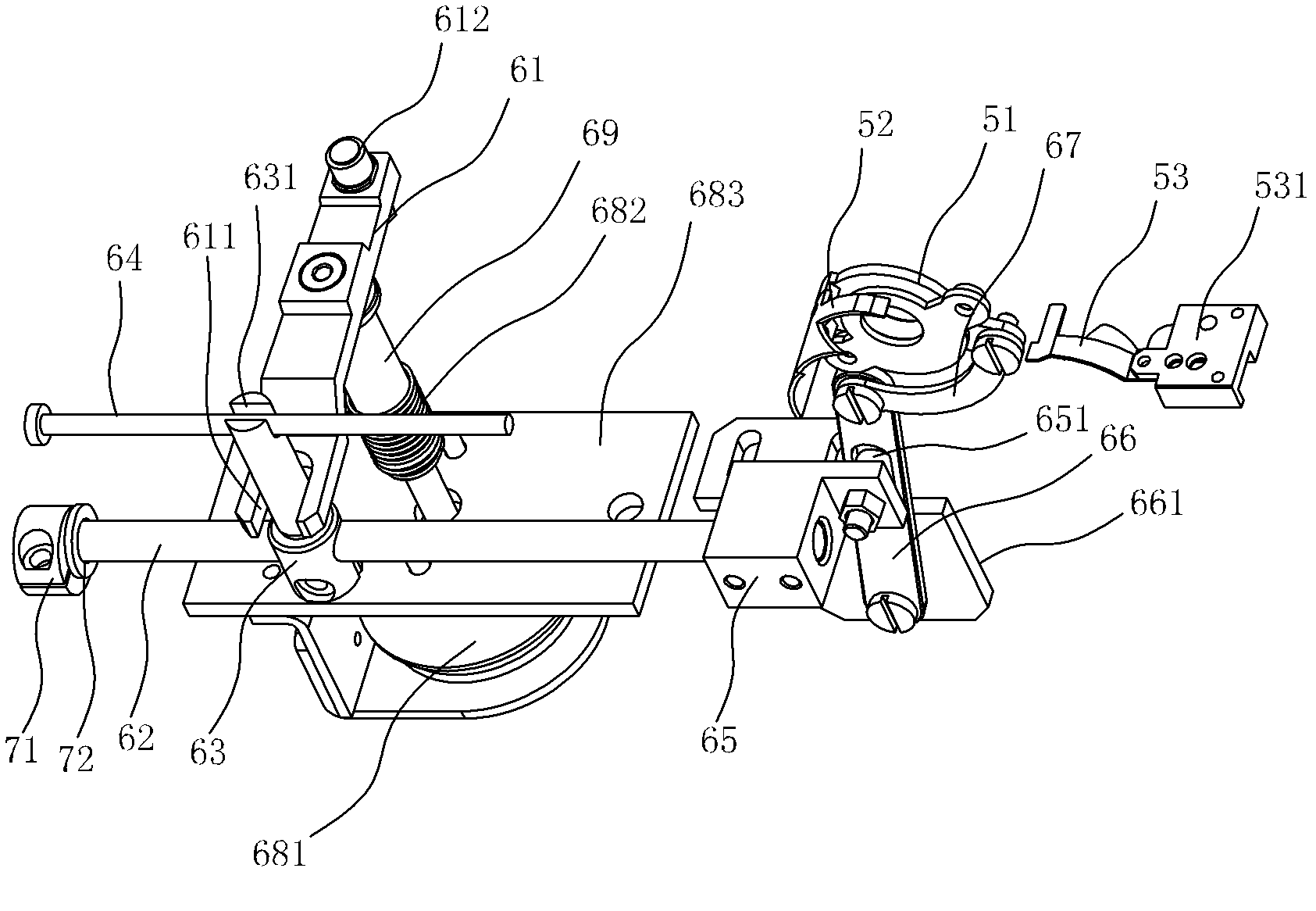

[0021] refer to figure 1 , figure 2 with image 3 As shown, an embroidery machine thread trimming device includes a lower shaft 3 horizontally arranged on the embroidery machine frame 1, a thread trimming cam 4 arranged on the lower shaft 3, a scissors mechanism, and a thread trimming cam 4. scissor drive mechanism.

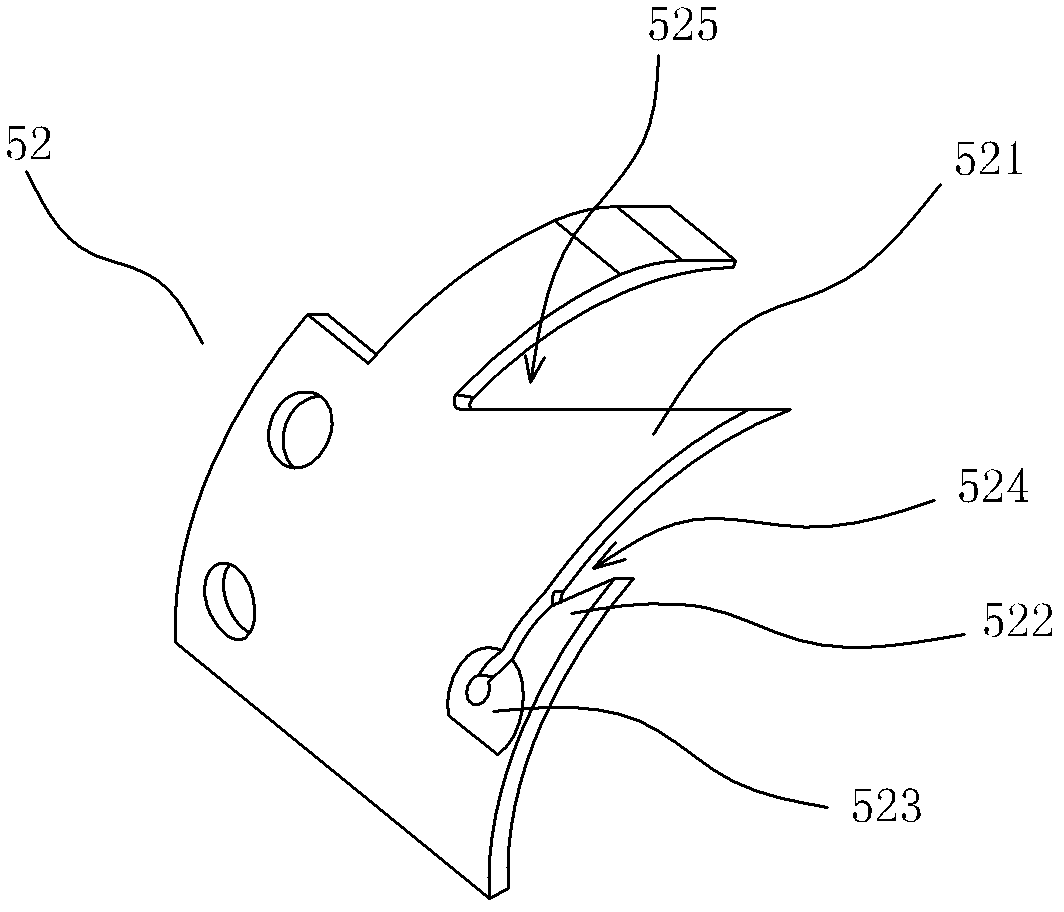

[0022] The scissors mechanism includes a movable knife seat 511 arranged on the frame 1, a rotating seat 51 which is rotatably arranged on the movable knife seat 511 around the center, fixedly arranged on the rotating seat 51 and can rotate around its center of circle with the rotating seat 51 The arc-shaped movable knife 52 and the fixed knife 53 that can be matched with the arc-shaped movable knife 52 are fixed on the frame 1 by the fixed knife seat 531. The front end of the movable knife 52 is formed with a hook line angle 522 and a line dividing angle 521 extending along the direction of rotation of the movable knife 52, and a thread cutting edge 524 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com