Temporary emergency road surface equipment

A kind of equipment and temporary technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of secondary pollution of the environment, and achieve the effects of saving energy, enhancing bearing capacity, and enhancing resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

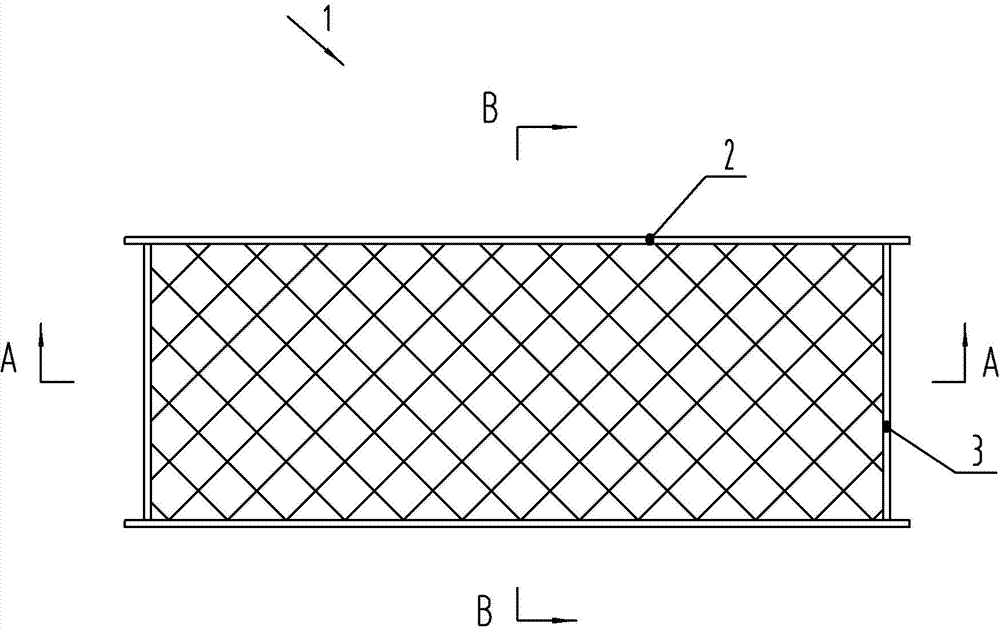

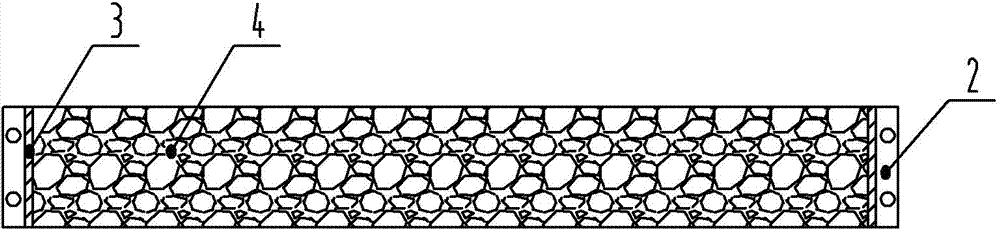

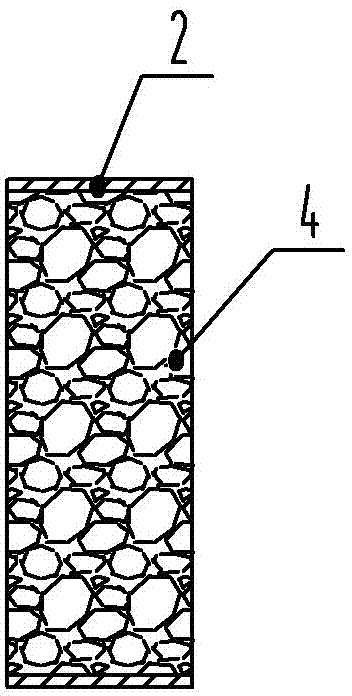

[0070] see figure 1 , figure 2 and Figure 5 , in the figure, the temporary emergency pavement equipment unit plate body of the present invention includes a pavement base body 1, and the pavement base body 1 includes a frame composed of two lateral side panels 2 and two vertical side panels 3, and a concrete layer is integrally poured inside the frame 4. The frame has four protruding ends, and mounting holes are provided at the four protruding ends. A set of black metal ribs 5 arranged horizontally and horizontally in one direction are also fixed inside the frame, and are close to the lower surface of the frame. The frame is rectangular, and the frame is fixedly connected by two lateral side panels 2 and two vertical side panels 3 arranged separately, and the lateral side panels 2 and vertical side panels 3 are made of flat steel plates. The surface has a non-slip pattern.

Embodiment 2

[0072] see figure 1 , image 3 and Figure 4 , in the figure, the meanings of the same numbered parts in this embodiment and the first embodiment are the same and will not be repeated. The difference is that a group of black metal ribs 5 arranged horizontally and vertically in one direction are also fixed inside the frame of this embodiment, and near the lower surface of the bezel.

Embodiment 3

[0074] see figure 1 , Figure 4 and Figure 5 , in the figure, the meanings of the same numbered parts in this embodiment are the same as in Embodiment 1 and will not be repeated. The difference is that a group of black metal ribs 5 that are bidirectionally crossed are fixed inside the frame described in this embodiment, and are close to the frame lower surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com