Concrete foundation pile

A technology of concrete foundation and horizontal steel bars, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low strength utilization rate of pile materials, waste, and the ability to bear loads needs to be improved, achieving simple structure, Convenience in construction and improvement of load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

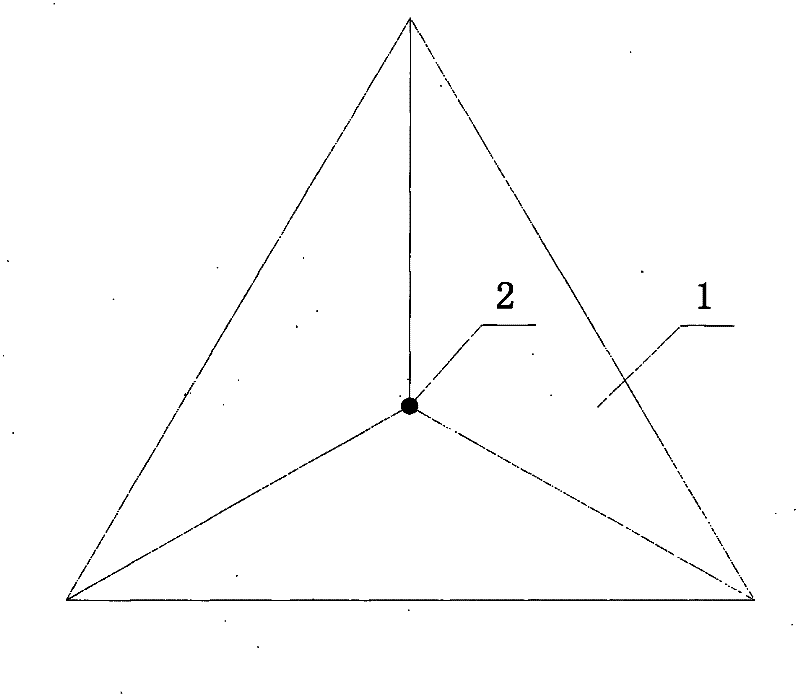

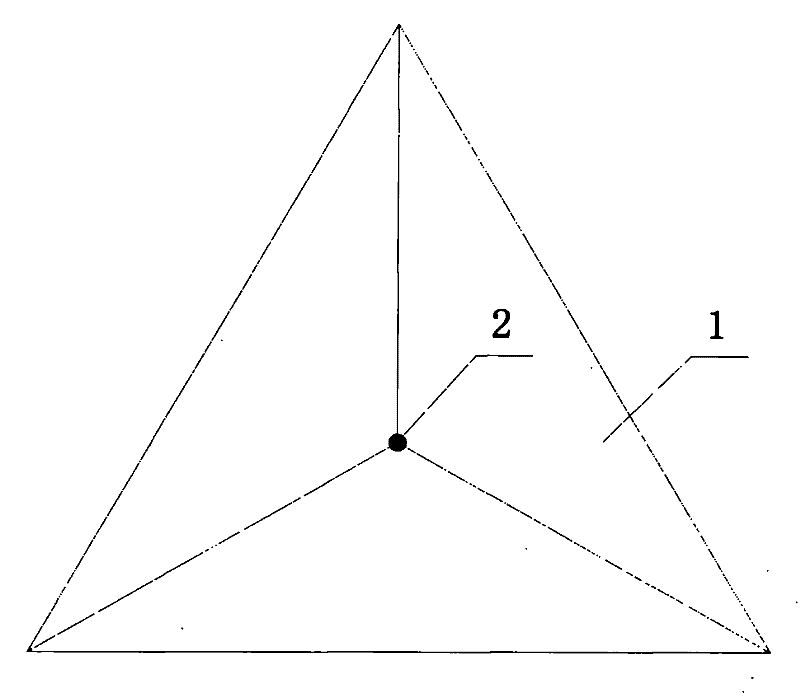

[0011] As shown in the accompanying drawings, the present invention is a concrete foundation pile, and its cross section is an equilateral triangle. In the equilateral triangle of the cross section, with its geometric center as the center, horizontal steel bars 1 are respectively connected to three vertices, and the horizontal steel bars 1 Distributed at equal intervals on the vertical plane. The intersections of the horizontal reinforcing bars 1 are connected with the vertical reinforcing bars 2. Described vertical reinforcing bar 2 is thicker than horizontal reinforcing bar 1.

[0012] If the material permits, the horizontal steel bar 1 is replaced by a steel plate, and the steel plate is consistent with the concrete foundation pile in the length direction and has the same length. Such a structure has a stronger load-bearing capacity and a higher utilization rate of the pile body material strength.

[0013] The invention improves the load-bearing capacity by arranging stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com