Grouted rubble and concrete combined gravity retaining wall

A technology of mortar block stone and concrete, which is applied in construction, artificial islands, infrastructure engineering, etc., can solve the problems of waste of materials and unreasonable materials for gravity retaining walls, etc., and achieve cost saving and good edge Slope support bearing capacity and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

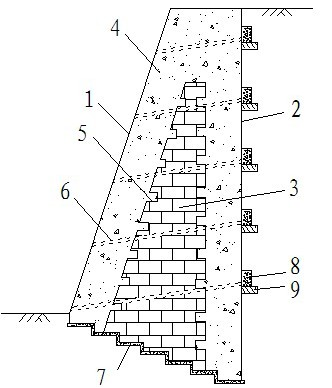

[0029] Embodiment 1: see figure 1 , a grout block stone and concrete combined gravity retaining wall, comprising a wall, the wall is composed of a grout block stone layer 3 and a concrete layer 4, the outside of the wall is a concrete layer, and the inside is a grout block Stone layer: The junction of the mortar block stone layer and the concrete layer is occluded together by the horse-tooth-shaped occlusal structure 5, which can avoid the formation of weak joints at the junction, effectively promote the synergy of the two materials, and prevent The two materials slide against each other for better stability. At the same time, only the inside is filled with mortar block stones, and the outside is made of high-strength concrete, which is suitable for slope projects with high height and high earth pressure. The bottom surface of the wall body is in a stepped shape, and its bottom surface is inclined downward along the outer side to the inner side, which can effectively improve ...

Embodiment 2

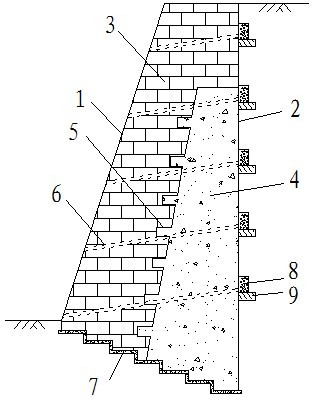

[0040] Example 2, see figure 2, and the difference from Example 1 is that the inner side (tension side) of the wall is a concrete layer 4, and the outer side (side of the free surface) is a mortar block stone layer 3. Using concrete instead of masonry blocks on the tension side of the retaining wall can effectively reduce the cross-sectional size of the original pure masonry block retaining wall. Because concrete has good performance-price ratio compared with masonry masonry in terms of tensile strength, the engineering cost of this retaining wall is lower than that of the previous pure masonry masonry retaining wall, and the bearing capacity of the retaining wall has not been weakened at the same time . At the same time, the inner side (tension side) of the wall is made of concrete material. Since the tensile strength of the mortar block stone is lower than that of concrete, the inner side (tension side) is made of concrete material when the height, width and section of the...

Embodiment 3

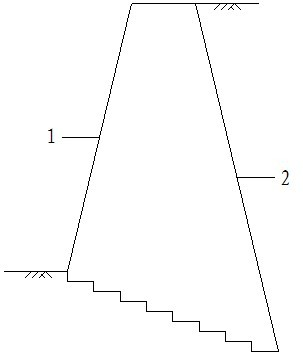

[0041] Example 3, see image 3 , the difference from Embodiment 1 or 2 is that the outer side 1 of the wall is tilted up and the inner side 2 is tilted down. The slope of the inner side of the wall is conducive to reasonably decomposing the earth pressure, increasing the anti-slip and anti-overturning stability coefficient of the retaining wall. Compared with Example 1, it is suitable for slope projects with higher height and greater earth pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com