Clamp used for board component, especially used for photovoltaic module

A plate element and fixture technology, applied in the field of thin-layer photovoltaic modules, can solve the problem of not having long-term clamping performance, and achieve the effect of good clamping effect, easy aging, and small contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

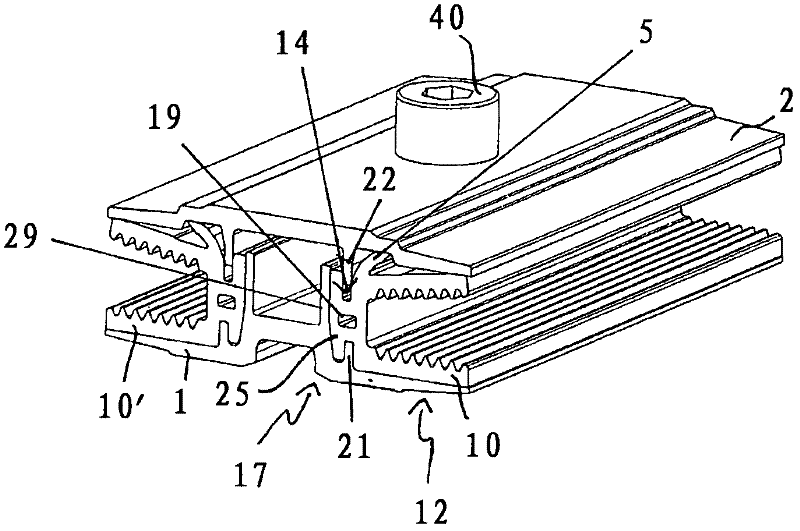

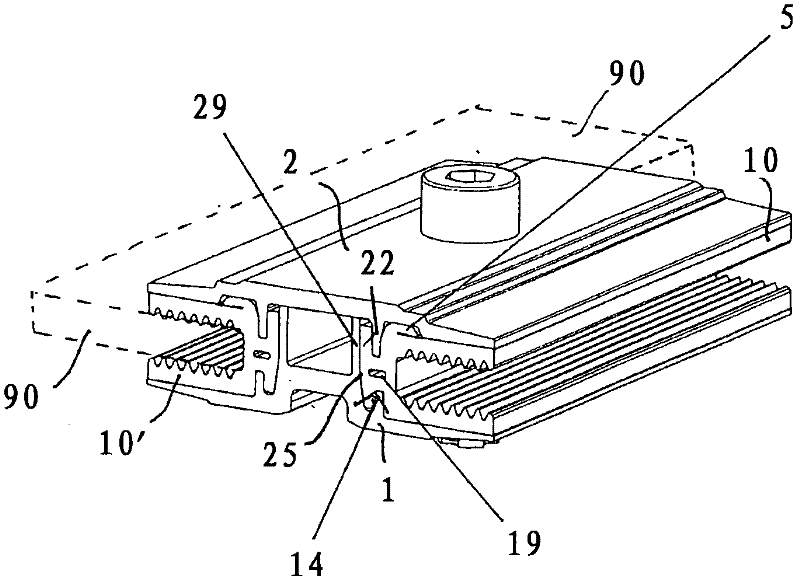

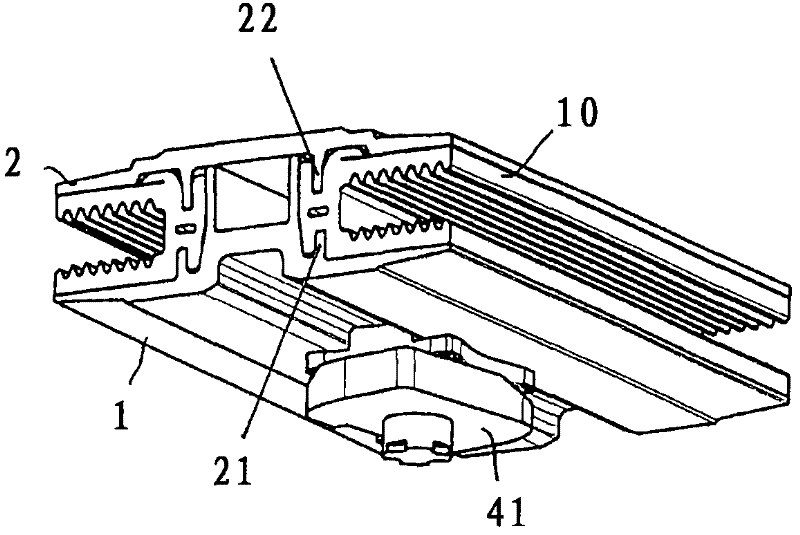

[0026] exist Figures 1 to 3 A first embodiment of a clamp according to the invention is shown in . figure 1 and 2 The embodiment of the embodiment is designed as a central clamp for fastening two plate elements and thus has two elastomer profiles 10 , 10 ′ for receiving a plate element each. For clarity, one such plate element 90 is only shown in figure 2 and is only shown there in the second elastomer molding 10'.

[0027] figure 1 The fixture configuration is substantially mirror-symmetrical. Therefore, only the elastomer molding 10 shown on the right in the figures and its arrangement will be described in detail below. The second elastomer molding 10' is similarly formed and arranged.

[0028] The clamping device shown has a first clamping part 1 and a second clamping part 2 which are displaceable relative to each other in the vertical direction. A screw 40 passes through the two clamping parts 1 and 2 in the vertical direction, and the screw is used for tensioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com