Method for preparing high-strength microbial mortar using urease-producing microorganisms

A microbial mortar and microorganism technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of soda damage, stiffness, strength mismatch, easy aging of organic materials, etc., and achieve splitting tensile strength. The effect of high strength, high resistance to fatigue and cyclic loading, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

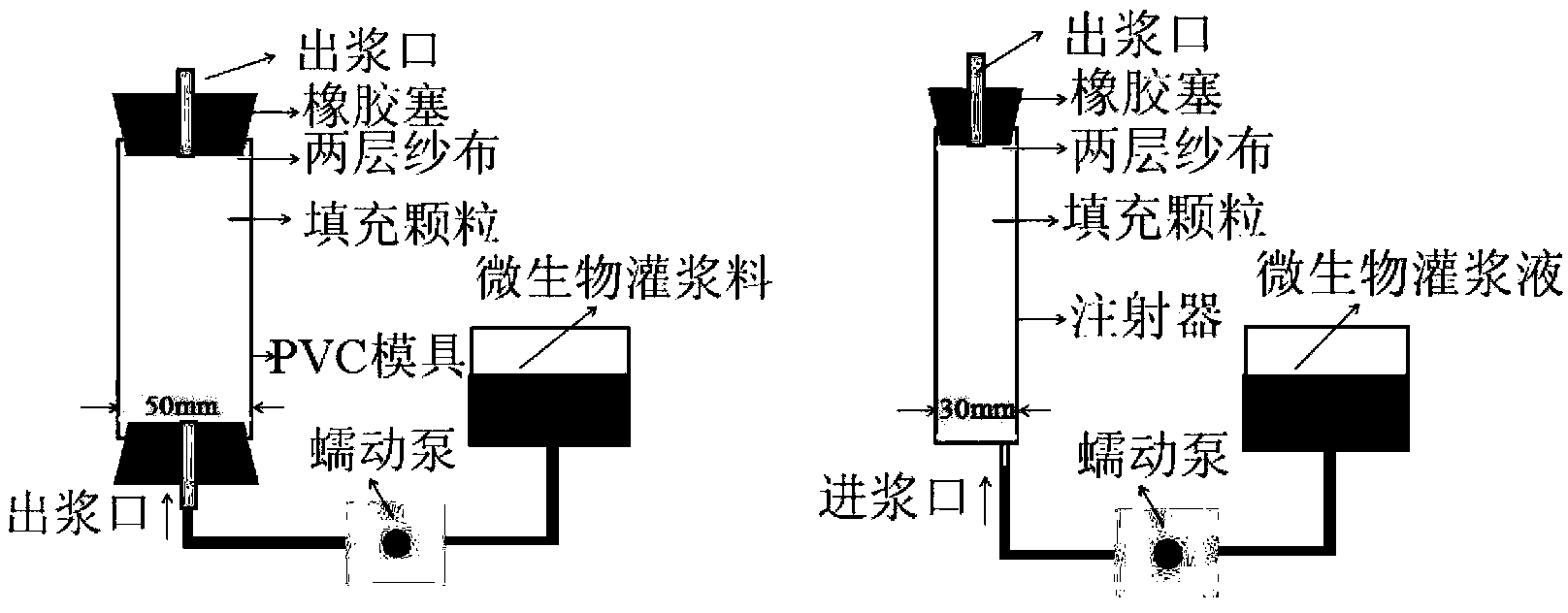

Method used

Image

Examples

Embodiment

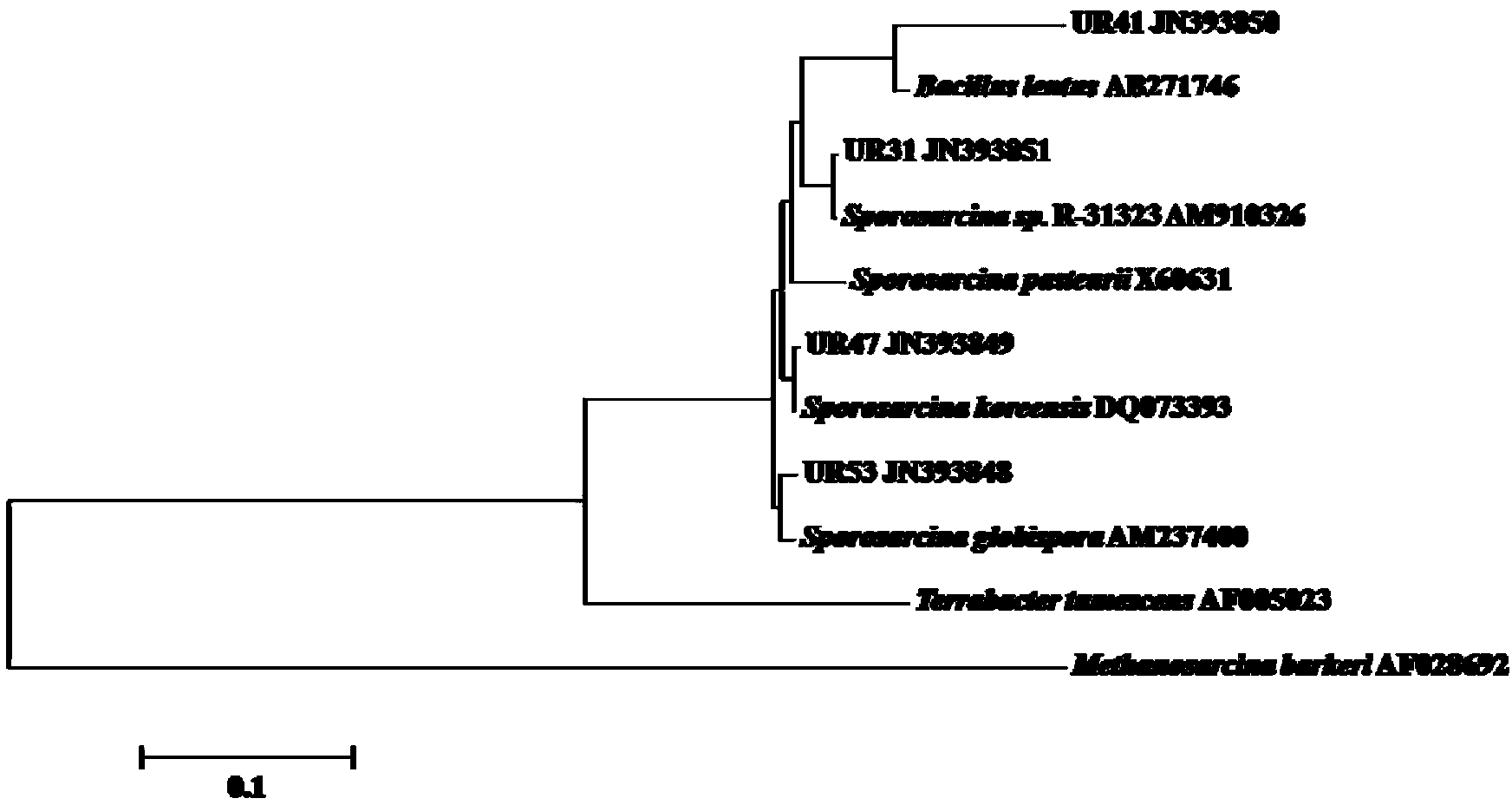

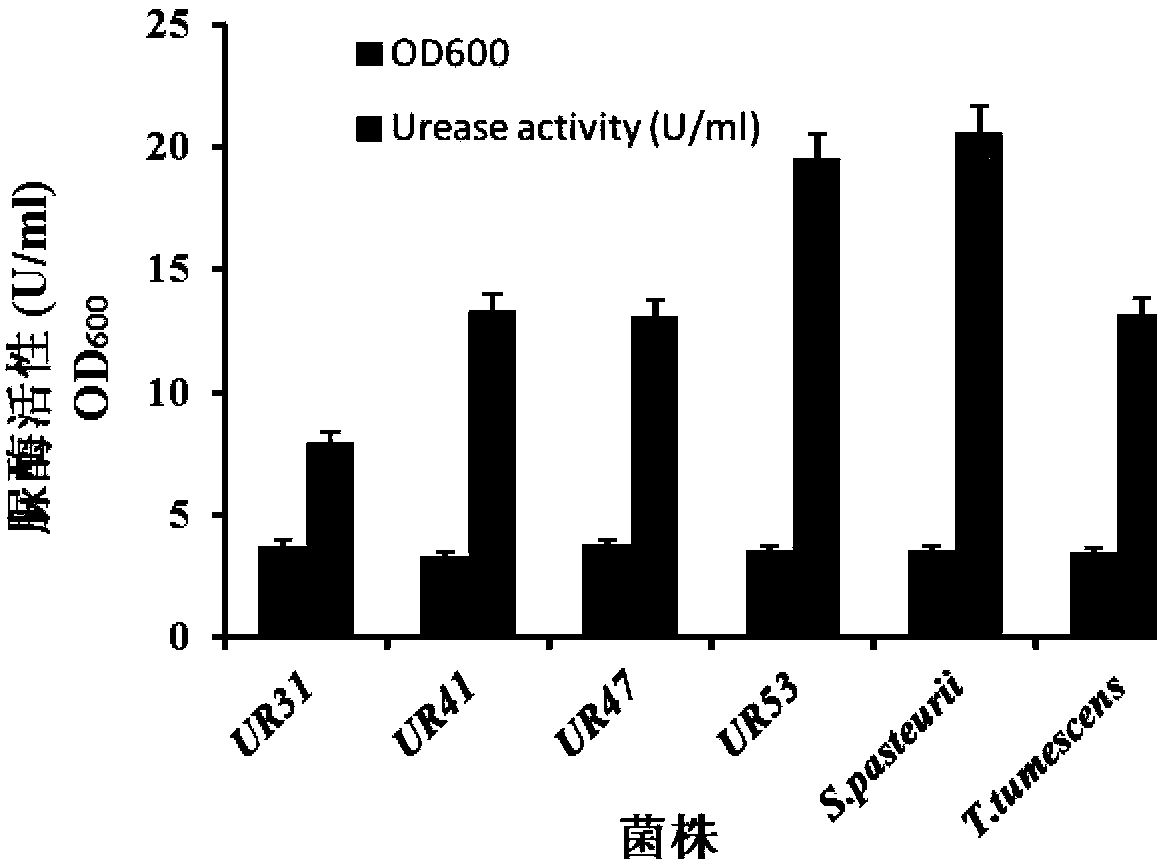

[0033] Isolation and Screening of Urease-Producing Bacteria with the Ability to Induce Artificial Sandstone

[0034] 1. Sample collection

[0035] Sporosarcina pasteurii was obtained from the American type culture collection (American type culture collection), numbered ATCC11859, and Terrabacter tumescens was obtained from the General Microbiology Center of China Committee for the Collection of Microbial Cultures, numbered AS.1.2690.

[0036] 2. Isolation and screening of urease-producing strains

[0037] Urease-producing strains were isolated from soil samples collected from the Tsinghua University flower garden.

[0038] Bacteria have ureolytic enzymes, which can decompose urea to produce a large amount of ammonia, making the medium alkaline and red. This experiment takes advantage of this characteristic. After enriching and culturing the test samples at 37°C and 5M high concentration of urea for 24 hours, kill various microbial vegetative cells that cannot tolerate and ut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com