Variable displacement rotor oil pump

A technology of rotor oil pump and displacement, applied in the direction of lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of engine power loss, increase oil volume, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

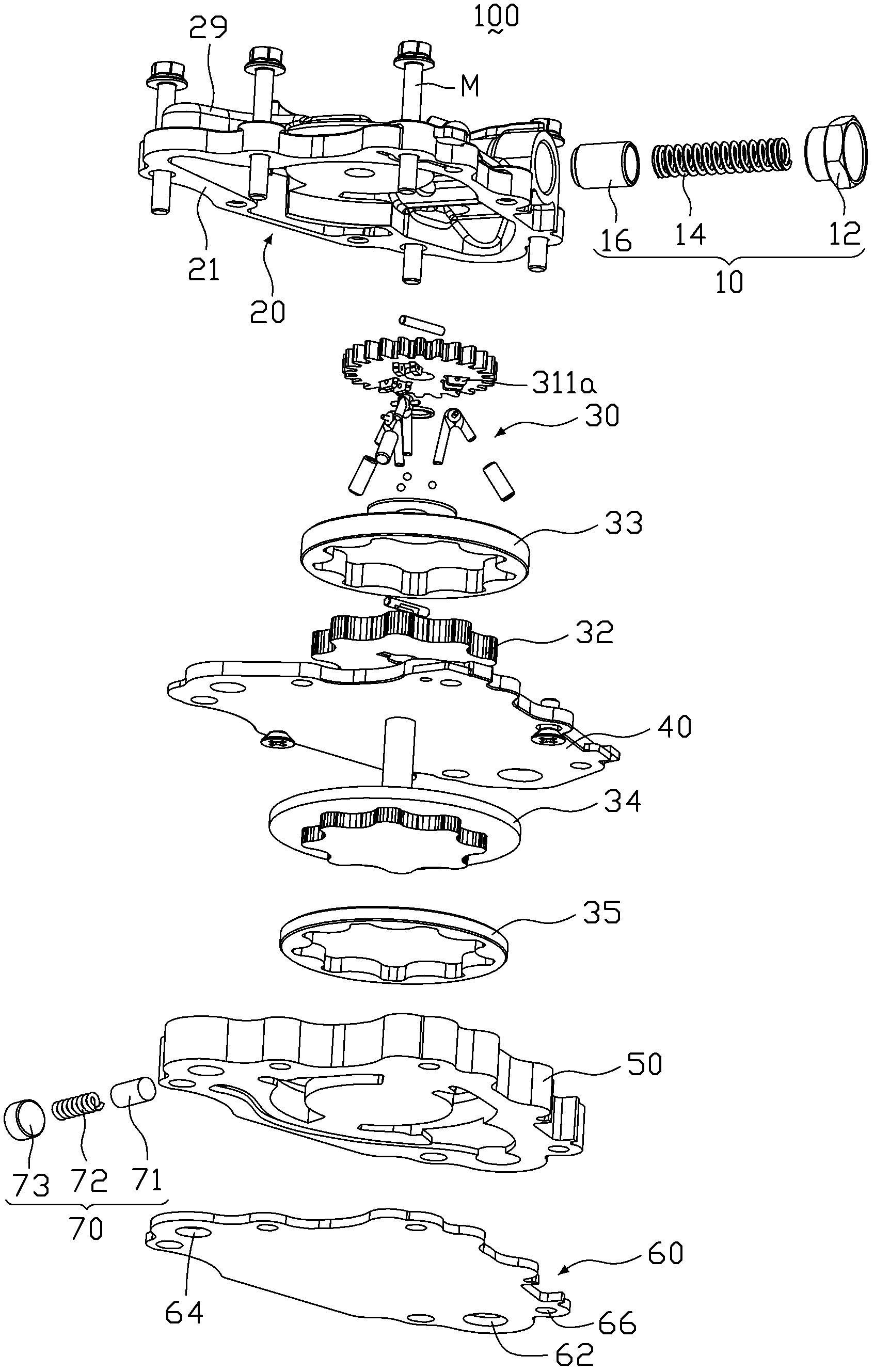

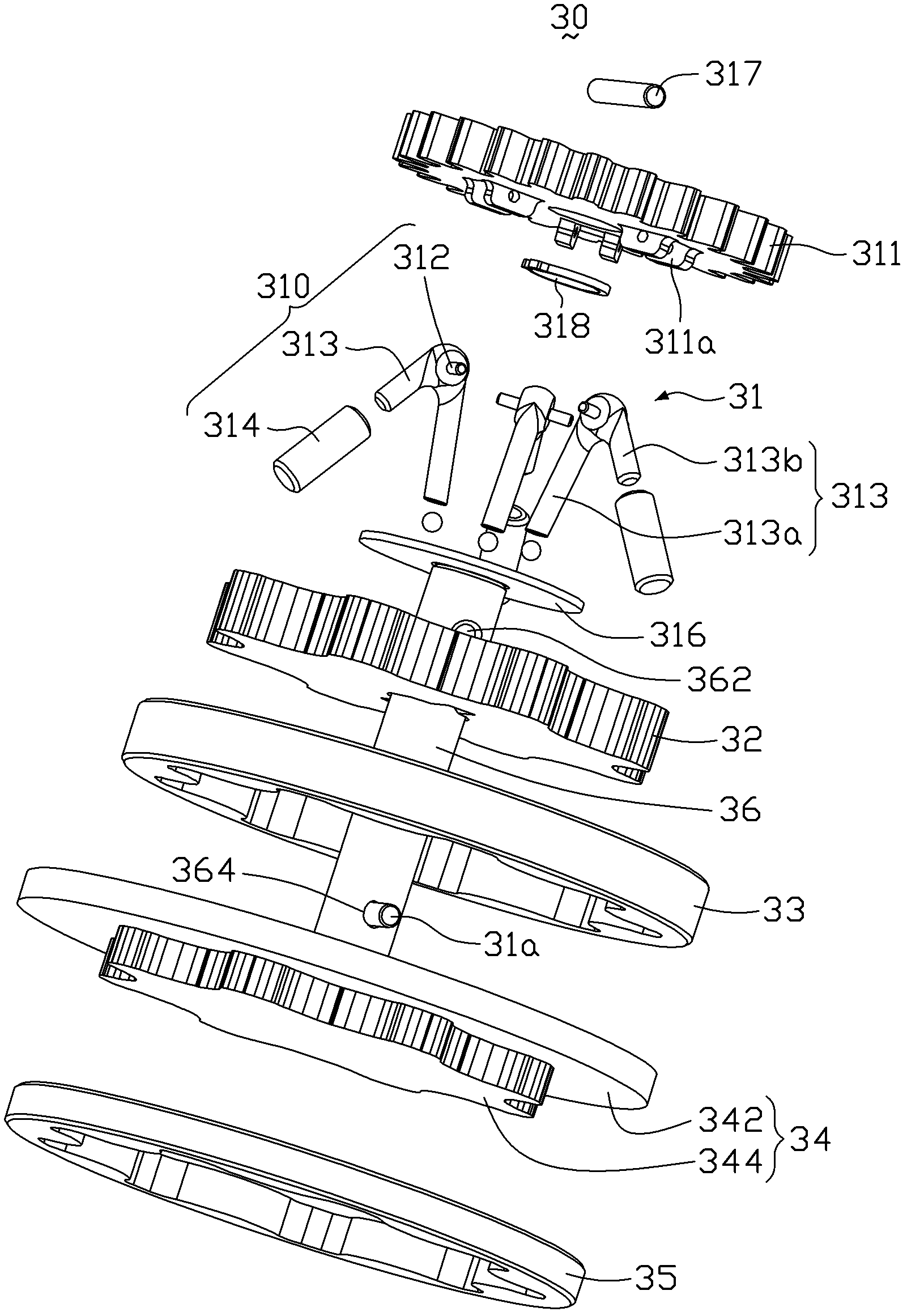

[0029] Please refer to figure 1 , the variable displacement rotor oil pump 100 of the preferred embodiment of the present invention includes a pressure relief valve module 10, a pump cover 20, a displacement adjustment structure 30, a driving gear 311, an intermediate cover plate 40, a pump casing 50, and a bottom end cover Plate 60, oil inlet valve module 70.

[0030] The pressure relief valve module 10 includes a screw plug 12 , a return spring 14 and a one-way valve 16 .

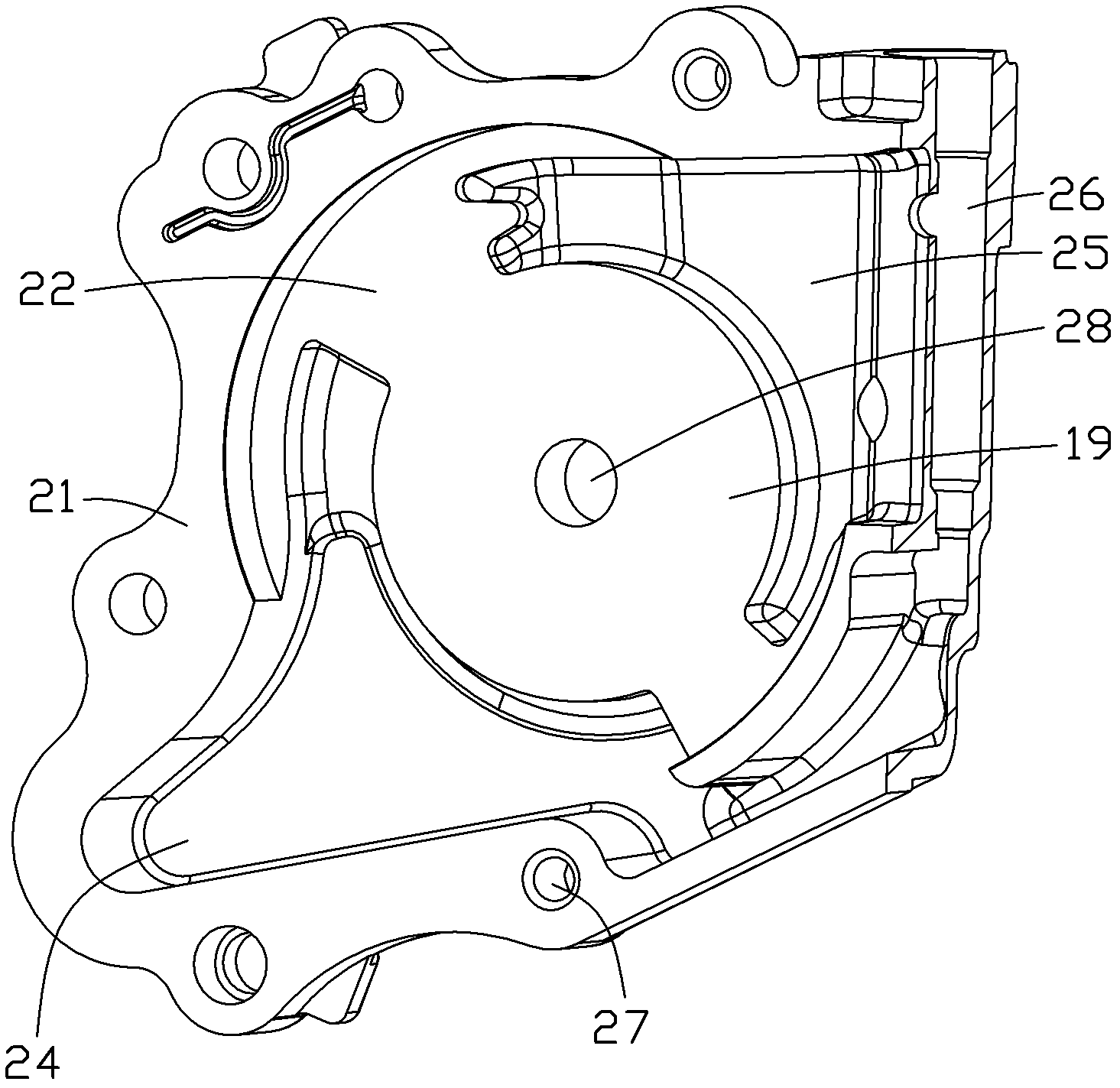

[0031] The pump cover 20 has a bottom surface 21 and a top surface 29, please refer to figure 2 , the bottom surface 21 is recessed to form an inner cavity 22 . An upper high-pressure oil area 24 and an upper low-pressure oil area 25 are arranged in the inner cavity 22 . The pump cover 20 is provided with a pressure relief hole 26 on one side of the upper low-pressure oil area 25 . The screw plug 12 , the return spring 14 and the one-way valve 16 are installed in the pressure relief hole 26 . The ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com