Sidelight type backlight source module

A backlight and edge-light technology, applied in the field of edge-light backlight modules, can solve problems such as uneven light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

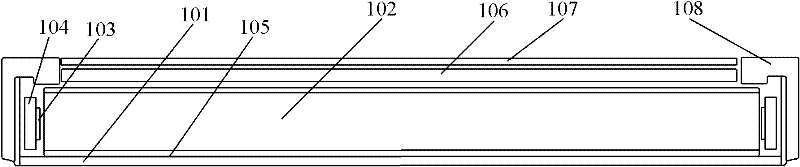

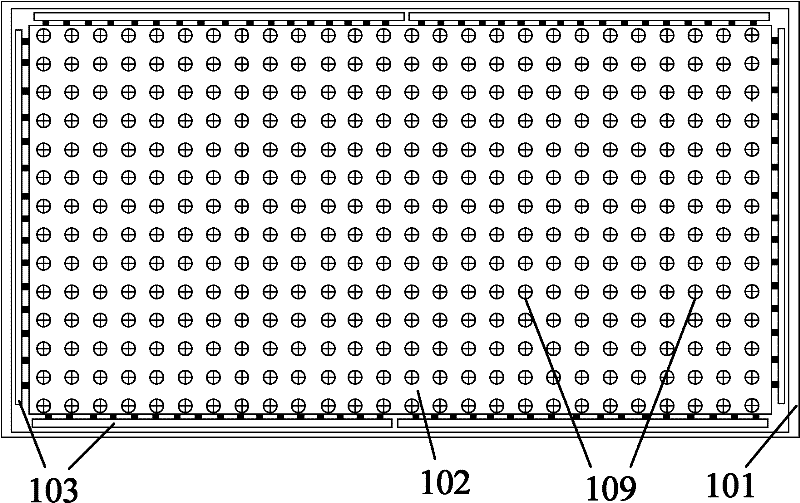

[0030] see image 3 and Figure 4 ,in image 3 It shows the side sectional view of the edge-lit backlight module of the present invention in the first embodiment, Figure 4 shown image 3 The top view of the edge-lit backlight module. combine image 3 and Figure 4 , the side-lit backlight module includes: a light source bracket composed of a backplane 201 and a plastic frame 208; a light guide plate 202 is arranged inside; A plurality of LED light sources are arranged on the strip 203 on a printed circuit board (PCB) 204 behind it; a reflective film 205 is provided under the light guide plate 202 . In practical applications, the LED light bar 203 emits light, and the light guide plate 202 is used to introduce light from the edge to the central area of the display screen, so that the entire display screen has enough backlight to allow the LCD screen to display images. Of course, in addition to this, the side-lit backlight module also includes other components, for exa...

no. 2 example

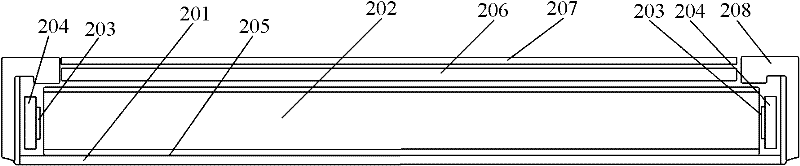

[0041] see Figure 5 and Figure 6 ,in Figure 5 It shows a side sectional view of the edge-lit backlight module of the present invention in the second embodiment, Figure 6 shown Figure 5 The top view of the edge-lit backlight module. to combine Figure 5 and Figure 6 , the side-lit backlight module includes: a light source bracket composed of a backplane 301 and a plastic frame 308; a light guide plate 302 is arranged inside; A LED light source is arranged on the printed circuit board 304 thereafter; a reflective film 305 is arranged under the light guide plate 302; Membrane group.

[0042] Compared with the design in the first embodiment in which LED light bars 203 are provided on two opposite sides of the light guide plate 202 , in the second embodiment, the LED light bar 303 is only provided on one side of the light guide plate 302 . Therefore, the light-incident bottom surface of the light guide plate 302 is provided with non-uniformly arranged scattering dots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com