Afterburner integrated with stabilizer and worm wheel rear rectification support plate

A technology of afterburner and rectifier support plate, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the special design of external flame stabilizer and organized combustion, the limited ability of flame stabilizer to stabilize flame, etc. problems, to achieve the effect of improving the thrust-to-weight ratio, compact design and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

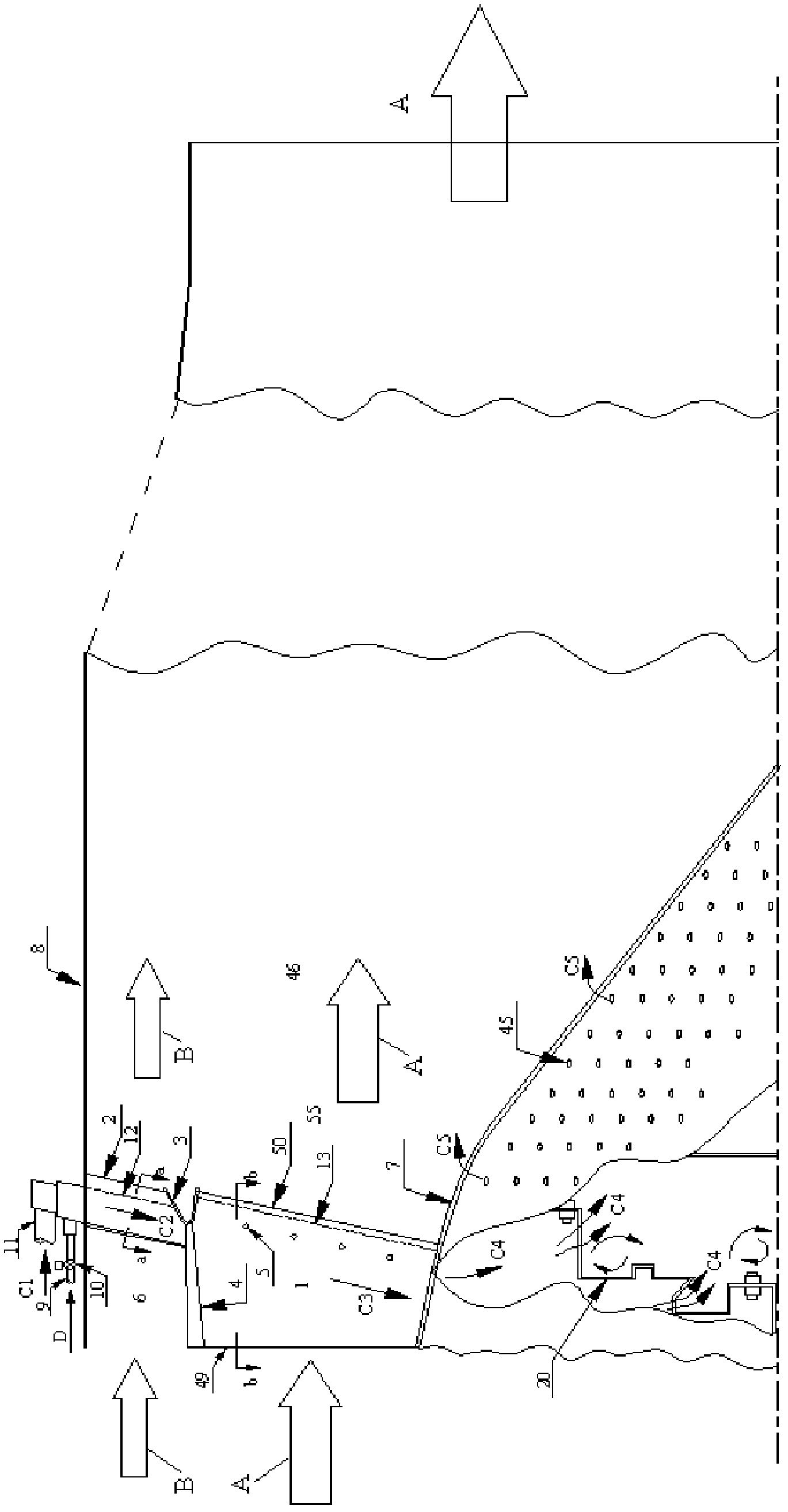

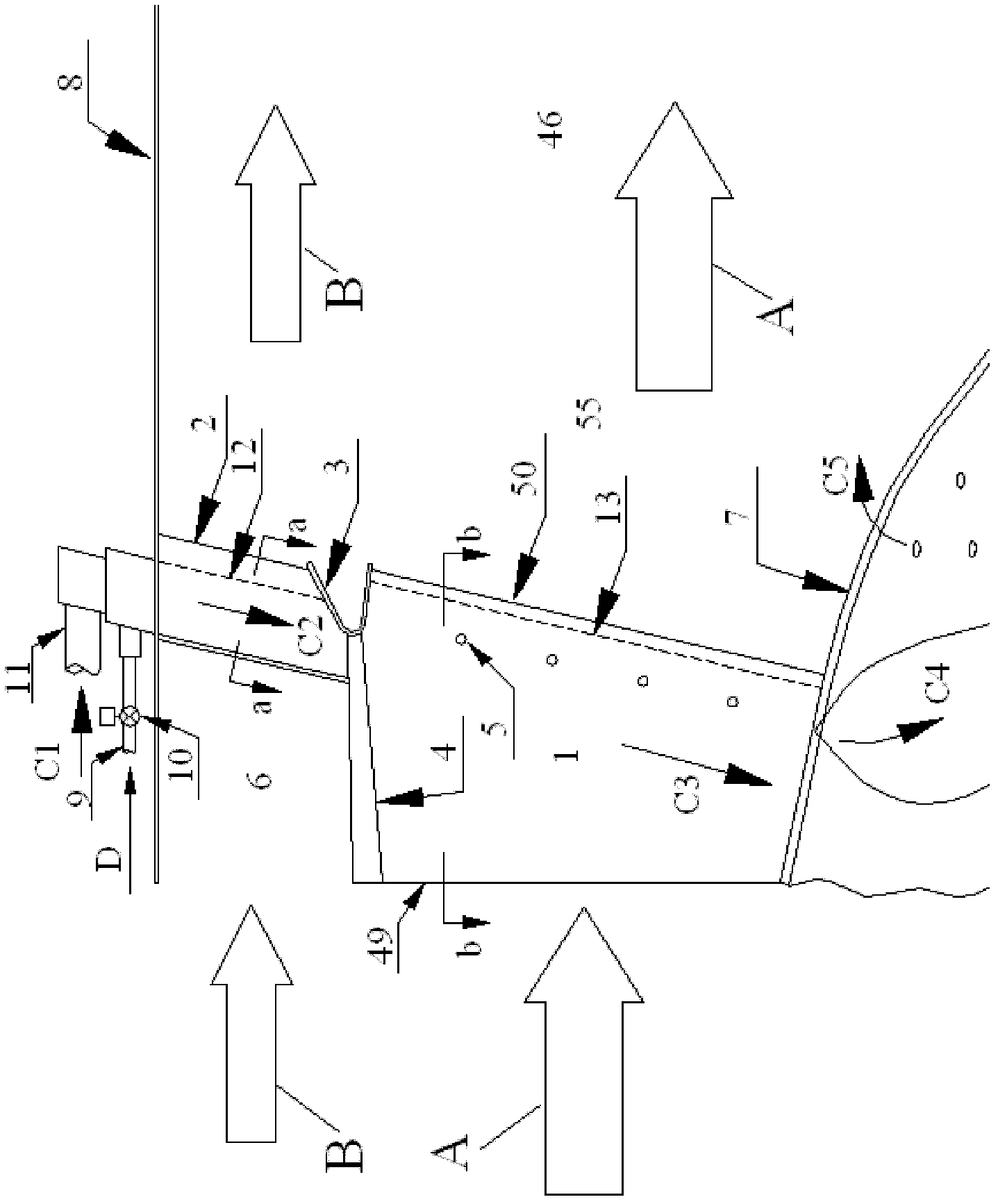

[0041] Below, in conjunction with the accompanying drawings, a technical solution for improving the utilization efficiency of engine components and improving the thrust-to-weight ratio of an afterburner integrated with a stabilizer and a turbine rear rectifying strut according to the present invention will be further described.

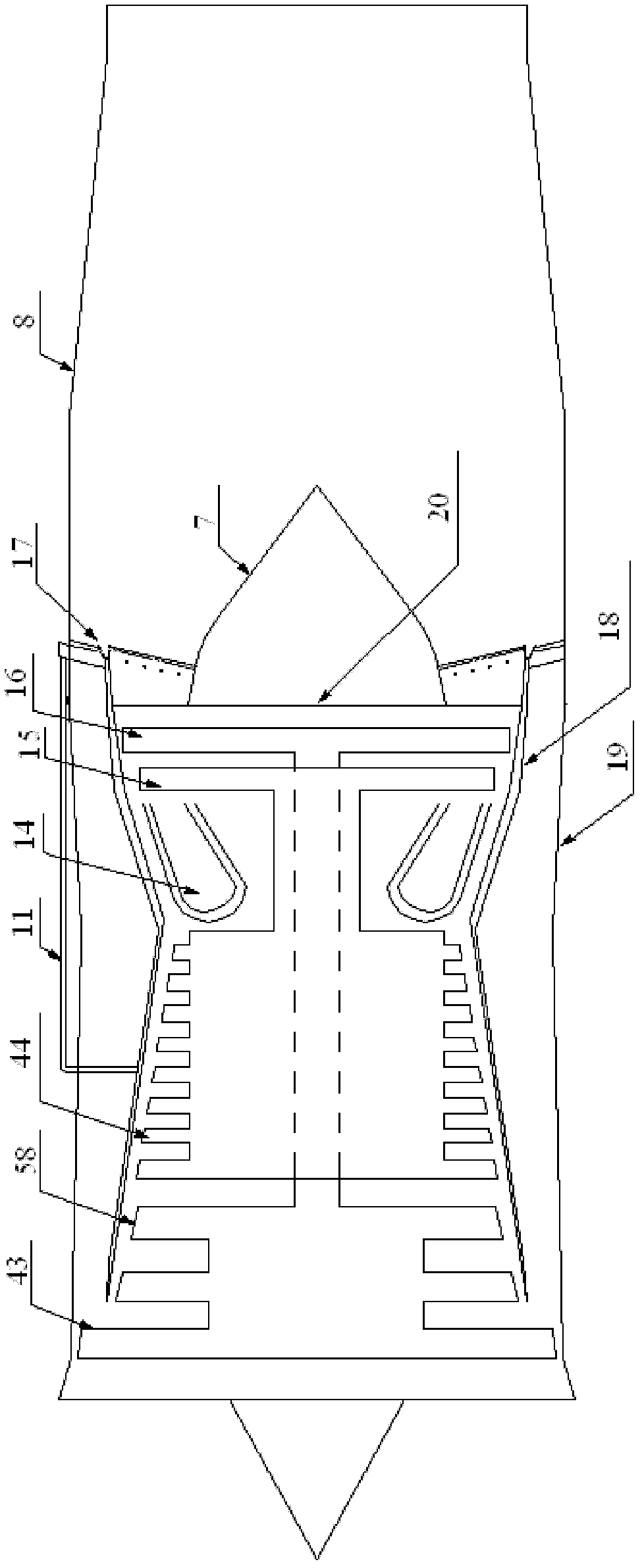

[0042] figure 1It is an overall schematic diagram of the engine, and the engine is generally composed of a fan 43, a low-pressure compressor 58, a high-pressure compressor 44, a main combustion chamber 14, a high-pressure turbine 15, a low-pressure turbine 16, an afterburner 17, an outer casing 19, a turbine casing 18, Rear bearing casing 20 forms. The afterburner of the present invention is equipped with a new generation of turbofan engine with small bypass ratio, the afterburner 17 is integrated with the turbine rear bearing frame, and itself is used as a part of the supporting frame, canceling the afterburner of the traditional design Components s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com