Heat collecting system with double-row solar vacuum tube matrix

A technology of solar energy and vacuum tubes, applied in the field of solar energy, can solve problems such as inability to obtain high-quality heat energy, inability to apply solar vacuum heat collection systems, and inability to achieve solar energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

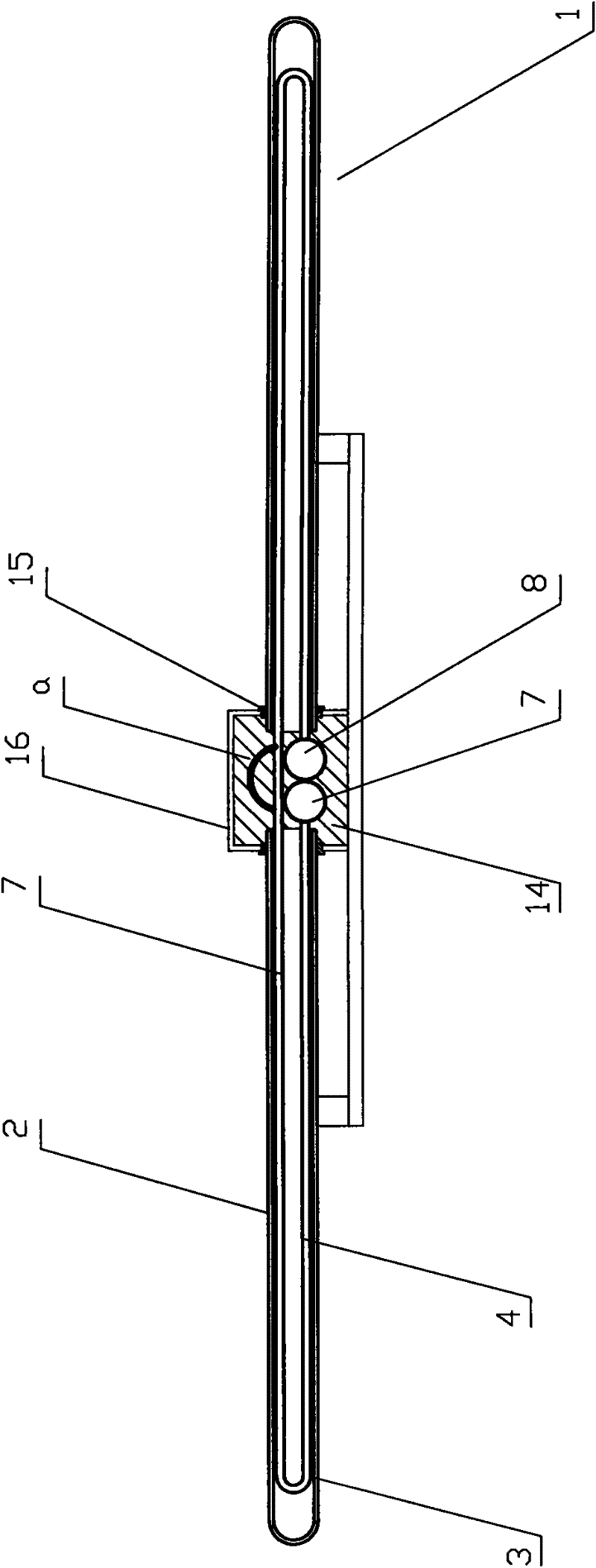

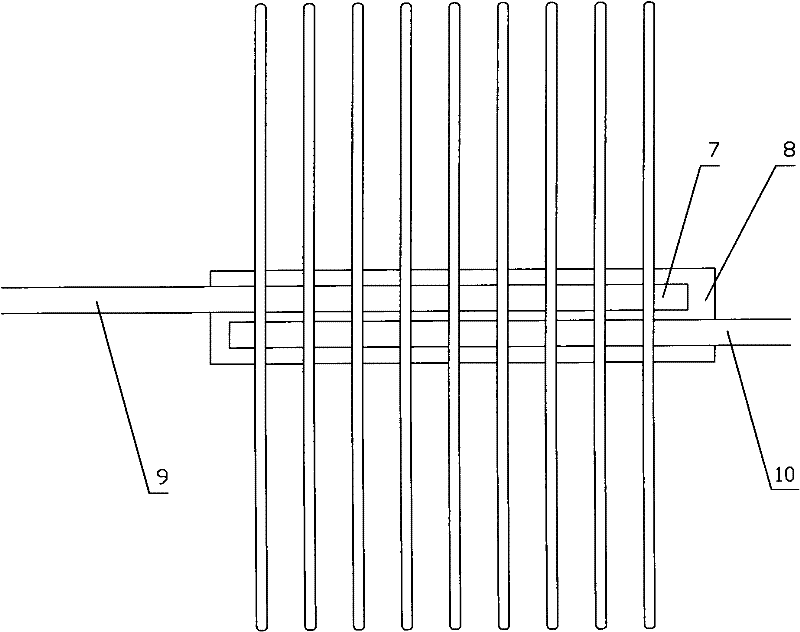

[0056] Figure 4 Shown is the front view of the solar vacuum tube matrix heat collection system of the present invention, it can be seen from the figure that the solar vacuum tube pairs 1 are neatly arranged in a matrix, wherein the structure of the solar vacuum tube pairs 1 is shown in figure 1 As shown, it consists of two solar vacuum tubes in series, the medium outlet of the U-shaped metal heat-conducting tube of the first solar vacuum tube is connected to the medium inlet of the U-shaped metal heat-conducting tube of the second solar vacuum tube connected to it, so that The series connection of the two solar vacuum tubes is realized by connecting the U-shaped metal heat-conducting tubes; the U-shaped metal heat-conducting tubes connected together of the two solar vacuum tubes have an included angle of α, wherein α is less than or equal to 180 °; the U-shaped metal heat pipe is inverted, and the glass outer tube 2 and glass inner tube 3 nested together are used to cover the...

Embodiment 2

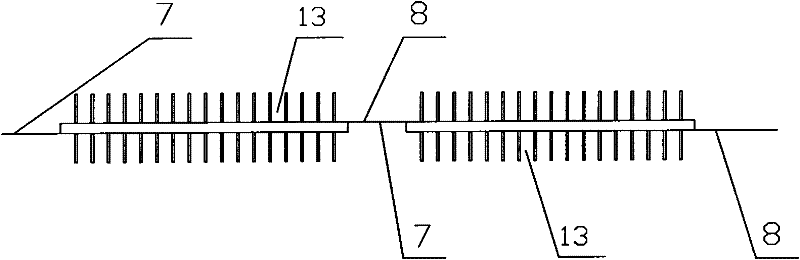

[0066] In this embodiment, a solar vacuum tube unit is also set between the water inlet main pipe 5 and the water outlet main pipe 6, and 250 solar vacuum tube tube groups 13 are arranged in the solar vacuum tube unit, and each solar vacuum tube tube The groups 13 all have a water inlet main pipe 7 and a water outlet main pipe 8, and 250 solar vacuum tube groups 13 are connected in series. When connecting, the water inlet main pipe 7 of the first solar vacuum tube group 13 is connected with the water inlet main pipe 5, Along the flow direction of the medium, the water outlet main pipe 8 of the 250th solar vacuum tube group 13 is connected to the water outlet main pipe 6 . In addition, along the flow direction of the medium, the water outlet main pipe 8 of the first solar vacuum tube group 13 is connected to the water inlet main pipe 7 of the second solar vacuum tube group 13 adjacent to it, and so on, the 249th The water outlet main pipe 8 of the solar vacuum tube group 13 is ...

Embodiment 3

[0072] In this embodiment, a solar vacuum tube unit is also set between the water inlet main pipe 5 and the water outlet main pipe 6, and 150 solar vacuum tube tube groups 13 are arranged in the solar vacuum tube 1 unit, and each solar vacuum tube The tube groups 13 all have a water inlet main pipe 7 and a water outlet main pipe 8, and 150 solar vacuum tube groups 13 are connected in series. When connecting, the water inlet main pipe 7 of the first solar vacuum tube group 13 is connected to the water inlet main pipe 5 , along the flow direction of the medium, the water outlet main pipe 8 of the 150th solar vacuum tube group 13 is connected to the water outlet main pipe 6 . In addition, along the flow direction of the medium, the water outlet main pipe 8 of the first solar vacuum tube group 13 is connected to the water inlet main pipe 7 of the second solar vacuum tube group 13 adjacent to it, and so on, the 149th The water outlet main pipe 8 of the solar vacuum tube group 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com