A twin-turbine hydraulic torque converter

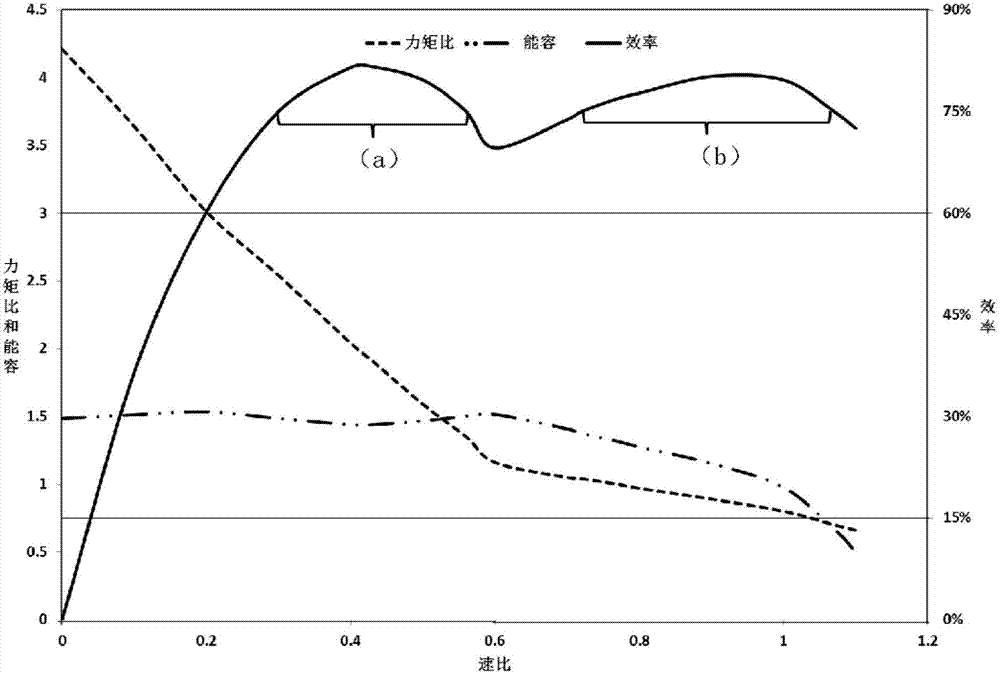

A hydraulic torque converter, twin-turbo technology, applied in belt/chain/gear, fluid transmission, mechanical equipment, etc., can solve the problems of uninvolved expansion and low operation efficiency, and achieve excellent fuel economy, The effect of saving time and economic cost and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

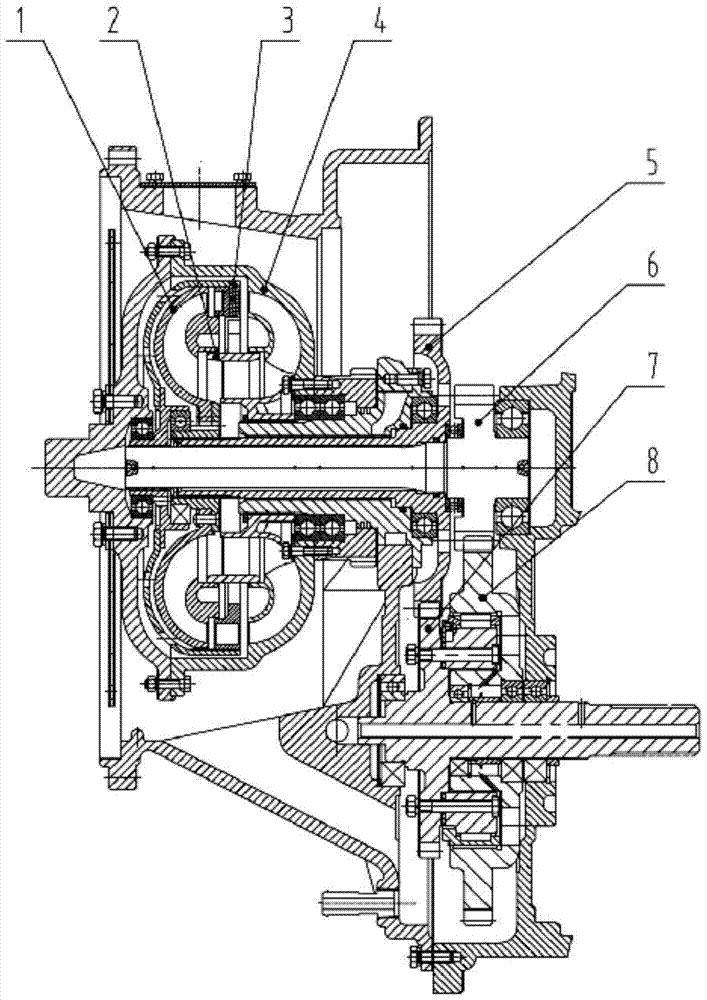

[0029] The preferred embodiment discloses a twin-turbine hydraulic torque converter. Such as figure 1 As shown, the twin-turbine hydraulic torque converter includes a first turbine 3, a second turbine 1, a guide wheel 2 and a pump wheel 4, and also includes a first turbine shaft 6 sleeved on the first turbine 3, sleeved on the second The second turbine shaft 5 on the second turbine 1, the first end gear 7 of the overrunning clutch and the second end gear 8 of the overrunning clutch, wherein the blades of the first turbine 3, the blades of the second turbine 1, and the blades of the guide wheel 2 and the blades of the pump impeller 4 form a cascade assembly.

[0030] Circulation circle diameter D: The maximum diameter of the space formed by the impeller flow channel and the inner and outer rings is called the effective diameter, that is, the diameter of the circulation circle; the radius of the round head of the blade inlet side and the round head radius of the outlet side: th...

Embodiment 2

[0038] The preferred embodiment discloses a twin-turbine hydraulic torque converter. The structure of the twin-turbine hydraulic torque converter is basically the same as that of the preferred embodiment 1, except that:

[0039]The blade inlet angle βb1 of the pump impeller 4 is 115°, the outlet angle βb2 is 60°, the placement angle γb is 130°, the radius Rb1 of the inlet side round head is 2.4mm, and the outlet side round head radius Rb2 is 1.3mm;

[0040] The blade inlet angle βs1 of the guide wheel 2 is 104°, the outlet angle βs2 is 148°, the placement angle γs is 133°, the radius Rs1 of the round head on the inlet side is 5.6mm, and the radius Rs2 of the round head on the outlet side is 1.3mm;

[0041] The blade inlet angle βt1 of the first turbine 3 is 112°, the outlet angle βt2 is 153°, the placement angle γt is 136°, the radius Rt1 of the round head on the inlet side is 5.5mm, and the radius Rt2 of the round head on the outlet side is 0.41mm;

[0042] The blade inlet a...

Embodiment 3

[0045] The preferred embodiment discloses a twin-turbine hydraulic torque converter. The structure of the twin-turbine hydraulic torque converter is basically the same as that of the preferred embodiment 1 or 2, except that:

[0046] The blade inlet angle βb1 of the pump impeller 4 is 119°, the outlet angle βb2 is 64°, the placement angle γb is 134°, the radius Rb1 of the round head on the inlet side is 2.4mm, and the radius Rb2 of the round head on the outlet side is 1.3mm;

[0047] The blade inlet angle βs1 of the guide wheel 2 is 108°, the outlet angle βs2 is 152°, the placement angle γs is 137°, the radius Rs1 of the round head on the inlet side is 5.6mm, and the radius Rs2 of the round head on the outlet side is 1.3mm;

[0048] The blade inlet angle βt1 of the first turbine 3 is 116°, the outlet angle βt2 is 157°, the placement angle γt is 140°, the radius Rt1 of the inlet edge is 5.5mm, and the radius Rt2 of the outlet edge is 0.41mm;

[0049] The blade inlet angle βⅡt1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com