Sodium glutamate drying fluidized bed

A sodium glutamate, fluidized bed technology, applied in drying, dryer, hearth furnace and other directions, can solve the problems of easy loss, easy generation and crystal formation, etc., and achieves easy operation, increased contact time, and energy saving. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

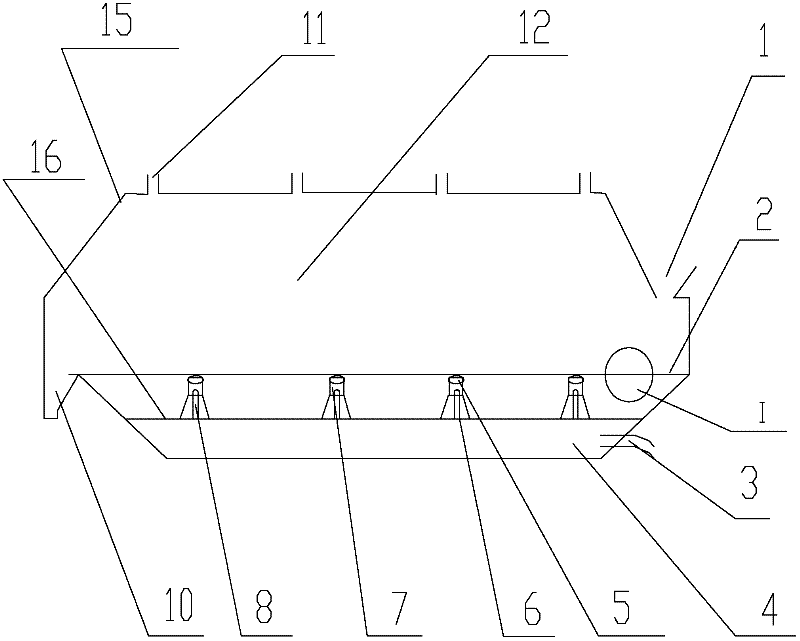

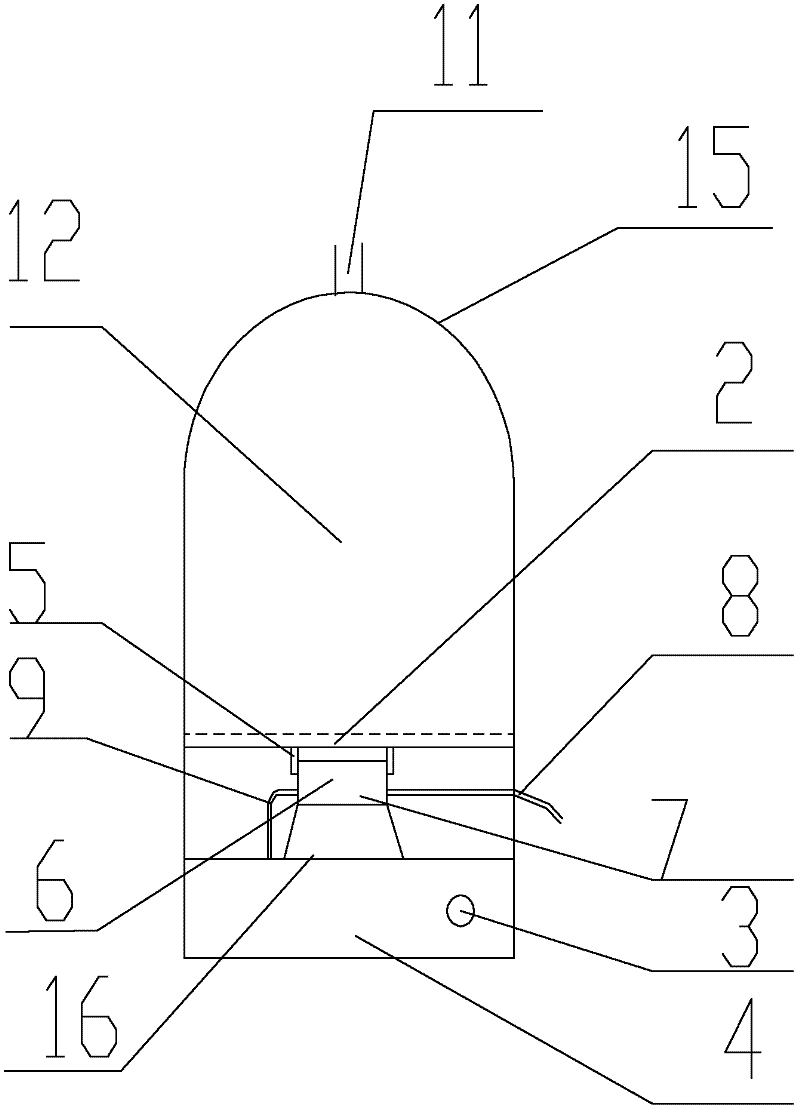

[0016] Attached below figure 1 , 2 , 3 describe an embodiment of the present invention.

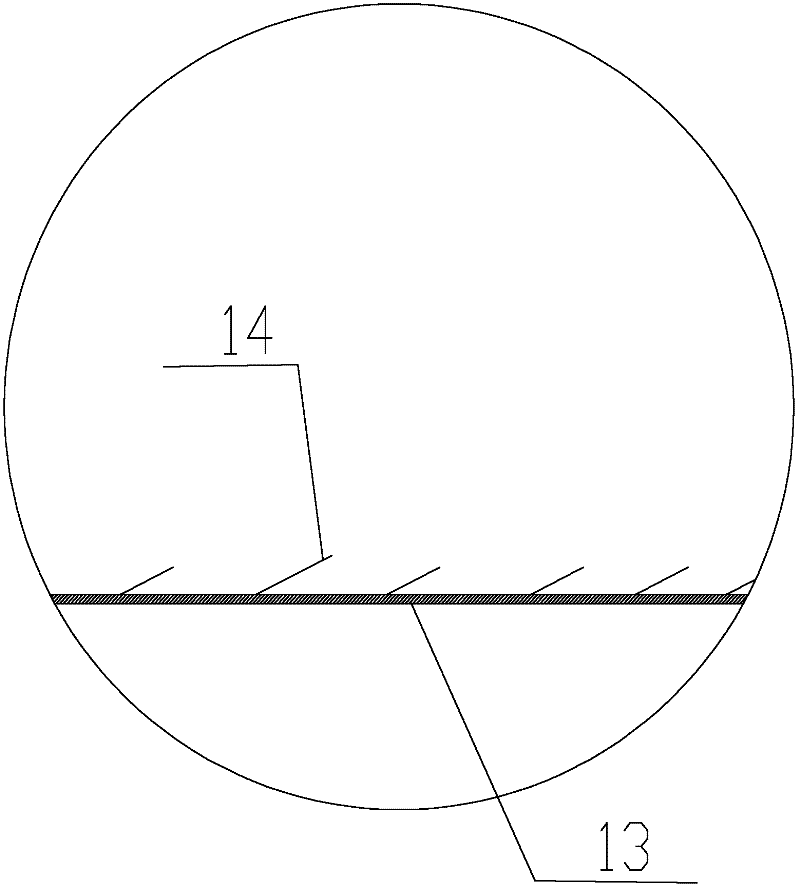

[0017] A sodium glutamate drying fluidized bed has a housing 15, and a partition 13 is horizontally arranged at the bottom of the housing 15 to separate the housing 15 into an upper airflow drying chamber 12 and a lower hot air buffer chamber 4; Both ends of the airflow drying chamber 12 are respectively provided with a feed inlet 1 and a discharge outlet 10, and the upper part is connected with a tail wind collecting device 11; Consists of an air motor 6 and a cam mechanism 5, the air motor 6 is fixed on the partition 16, the air inlet of the air motor 6 is connected to the hot air source through the motor air inlet pipe 8, and the air outlet is collected by the tail wind of the motor The pipe 9 communicates with the hot air buffer chamber 4, and the air motor 6 drives the cam mechanism 5, and the cam mechanism 5 is located below the sieve plate 2 to push the sieve plate 2 to vibrate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com