Smoke-type lithium bromide absorption type water chiller-heater unit for heating and normal temperature smoke exhaust

A technology of hot water unit and heating absorber, which is applied in the direction of adsorption machines, refrigerators, climate change adaptation, etc. It can solve the problems that affect the comprehensive utilization rate of system energy, high exhaust gas temperature, waste energy, etc., and achieve comprehensive energy utilization The effect of improving the efficiency, protecting the environment and eliminating white smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

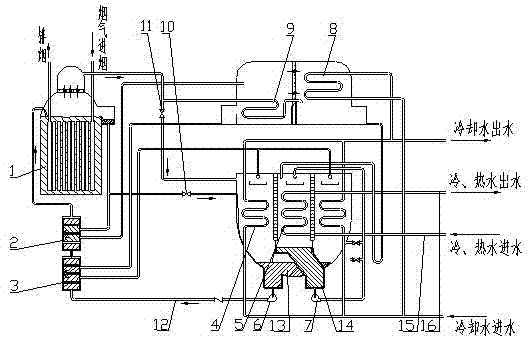

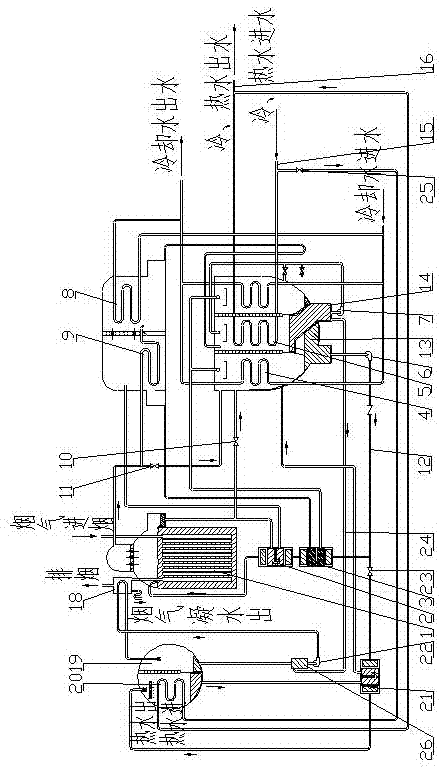

[0036] Such as figure 2 As shown, in the past flue gas lithium bromide absorption cold and hot water units such as figure 1 On the basis of the above, the unit adds a flue gas heat exchanger 18, a flash evaporator 19, a heating absorber 20, a heating solution heat exchanger 21 and a heating refrigerant pump 22, and the flue gas heat exchanger 18 is set at the high-pressure flue gas generation On the exhaust pipe of the device 1, the flash evaporator 19 and the heating absorber 20 are arranged in the same cavity, and placed at a position higher than the parts of the evaporator 5 and the absorber 4, and an additional circuit is installed on the cold and hot water inlet pipe 15 of the unit The hot water pipeline, the hot water enters the heat exchange tube of the heating absorber 20, and the heating hot water switching valve 25 is set on the hot water pipeline. Hot water is connected to the cold and hot water outlets of the unit; a dilute solution pipeline is added on the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com