Infrared broadband transmission type plastic film thickness measuring device and infrared broadband transmission type plastic film thickness measuring method

A plastic film and thickness measurement technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor accuracy and poor versatility, and achieve the effect of improving versatility and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

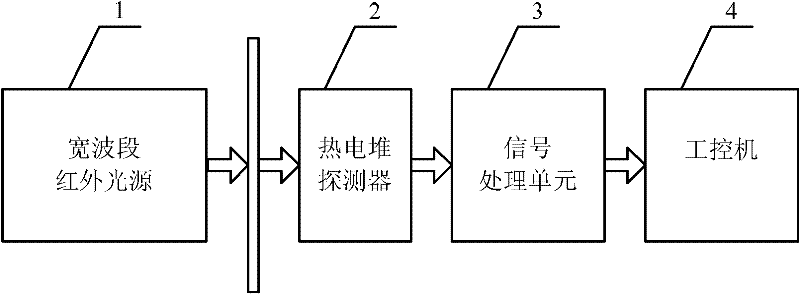

[0021] Specific implementation mode one: the following combination figure 1 Illustrate this embodiment, the infrared wide-band transmissive plastic film thickness measurement device described in this embodiment, it includes a broadband infrared light source 1, it also includes a thermopile detector 2, a signal processing unit 3 and an industrial computer 4,

[0022] The outgoing light of the broadband infrared light source 1 is incident on the plastic film to be tested, and is received by the thermopile detector 2 after being transmitted through the plastic film to be tested, and the electrical signal output end of the thermopile detector 2 is connected to the electrical signal input end of the signal processing unit 3 , the digital signal of the signal processing unit 3 is transmitted to the industrial computer 4 through the serial communication interface.

[0023] In this embodiment, a reflective cup can also be provided. The reflective cup is placed at the rear of the broa...

specific Embodiment approach 2

[0024] Specific implementation mode two: the following combination figure 1 Describe this embodiment. This embodiment is a method for measuring the thickness of a plastic film based on the infrared wide-band transmission type plastic film thickness measuring device described in Embodiment 1. The outgoing light of the broadband infrared light source 1 is absorbed and scattered by the measured plastic film. Afterwards, it is received by the thermopile detector 2, and the thermopile detector 2 converts the received optical signal into an electrical signal and outputs it to the signal processing unit 3, and the signal processing unit 3 calculates and obtains the optical power information according to the received electrical signal and passes The serial communication interface transmits to the industrial computer 4, and the industrial computer 4 obtains the thickness value of the measured plastic film through calculation.

specific Embodiment approach 3

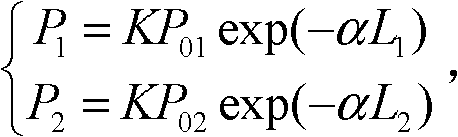

[0025] Specific embodiment three: this embodiment is a further description of embodiment two. The specific method for obtaining the thickness value of the measured plastic film by the industrial computer 4 described in this embodiment is as follows:

[0026] According to the formula: P=KP 0 exp(-αL),

[0027] In the formula, P is the optical power of the transmitted light output by the signal processing unit 3, K is the calibration coefficient, and P 0 is the outgoing light power of the broadband infrared light source 1, α is the extinction coefficient of the measured plastic film, L is the thickness of the measured plastic film,

[0028] Solve to obtain the thickness L of the measured plastic film.

[0029] In this embodiment, the calibration coefficient K and the extinction coefficient α of the measured plastic film can be obtained by measuring two known thicknesses L 1 and L 2 The standard thin film is obtained, which can be solved by the following two-variable equation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com