Integrated detection system for thermal performance of lower-medium vacuum compound insulation pipeline and application of integrated detection system

A composite thermal insulation and integrated detection technology, applied in the direction of material thermal development, etc., can solve problems such as composite thermal insulation pipes that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

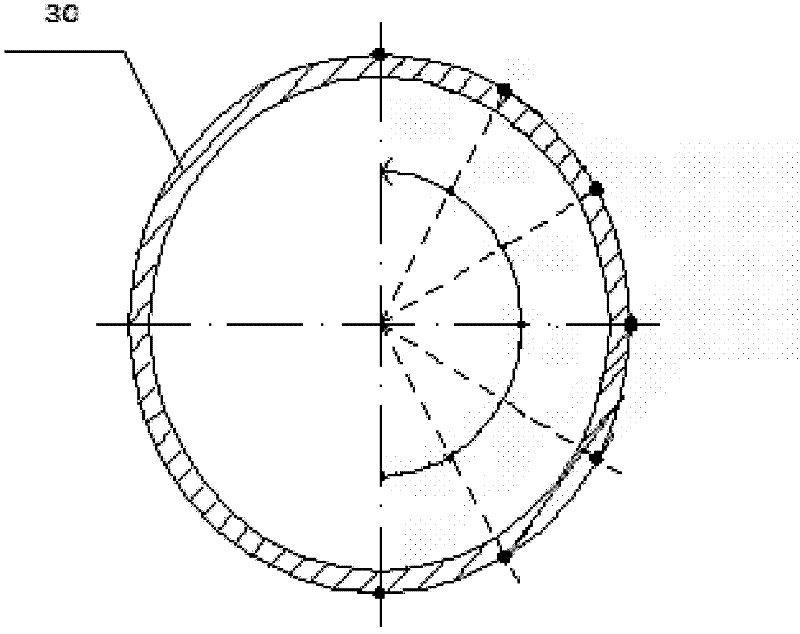

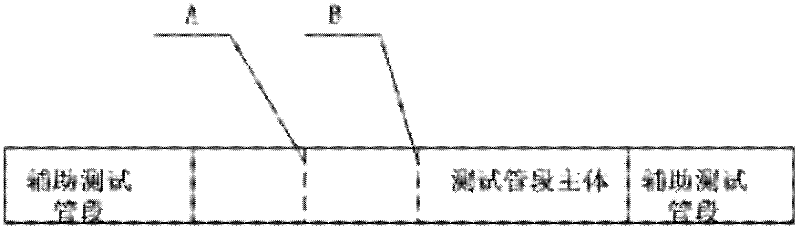

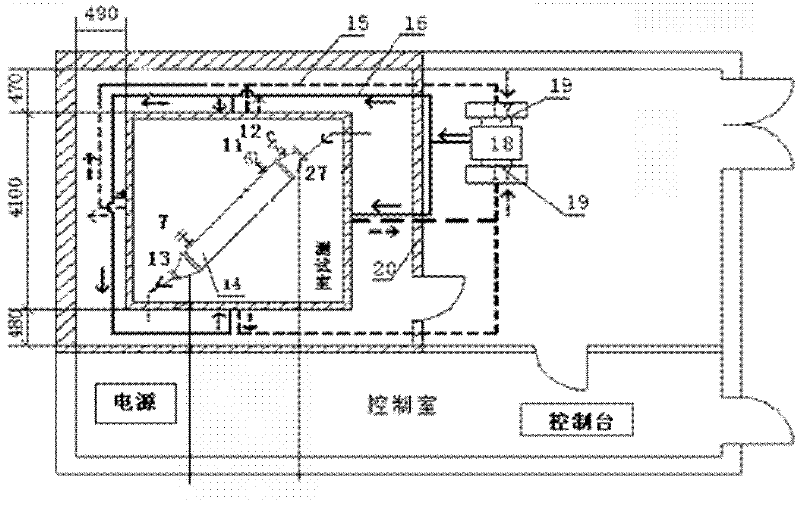

[0049] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0050] An integrated detection system for the thermal performance of a low-medium vacuum composite thermal insulation pipeline is composed of a control and data acquisition system, a heat transfer oil circulation system and a constant temperature chamber.

[0051] Such as figure 1 As shown, the structure of the control and data acquisition system is as follows: the industrial control computer is respectively connected to the printer and the RS232 bus 1, the RS232 / 485 converter is respectively connected to the RS232 bus 1 and the RS485 bus 21, and the RS485 bus 21 is respectively connected to the first 1 temperature sensor T1-the 48th temperature sensor T48, the first heat flow sensor Q1-the 16th heat flow sensor Q16, the first power module DL1-the third power module DL3 and the first intelligent regulator Trk1-the third intelligent regulator Trk3 are connected, ;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com