Wide-range precise measuring circuit for resistance of nano sensor and method

A resistance measuring instrument and sensor technology, applied in the direction of measuring electrical variables, measuring resistance/reactance/impedance, measuring devices, etc., can solve the problems of unrealistic measurement, error of measurement results, low accuracy of measurement results, etc., and achieve the solution of zero point and its Dynamic drift, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

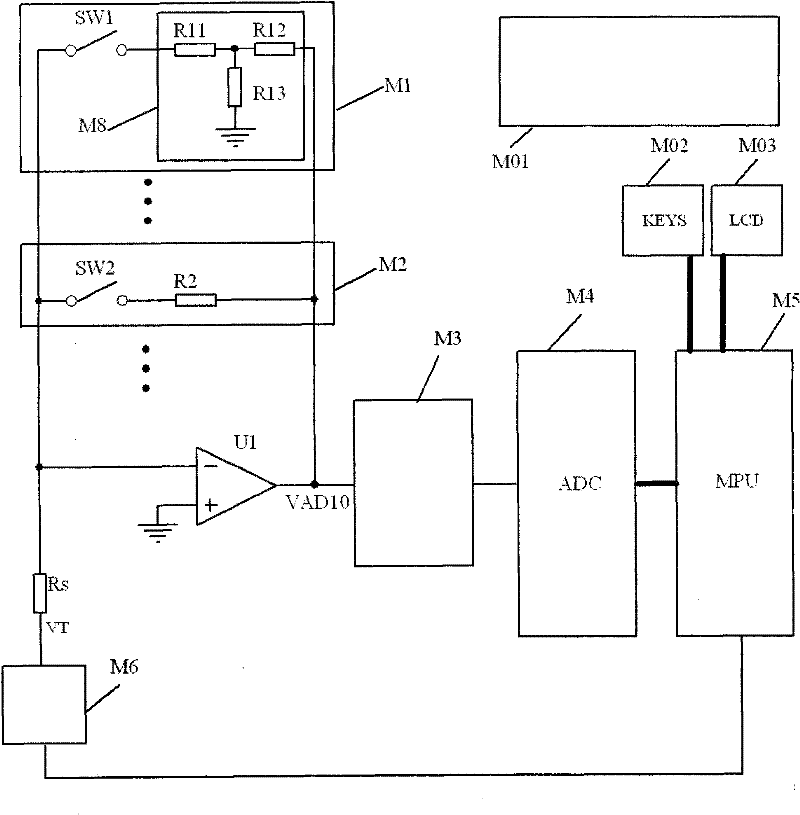

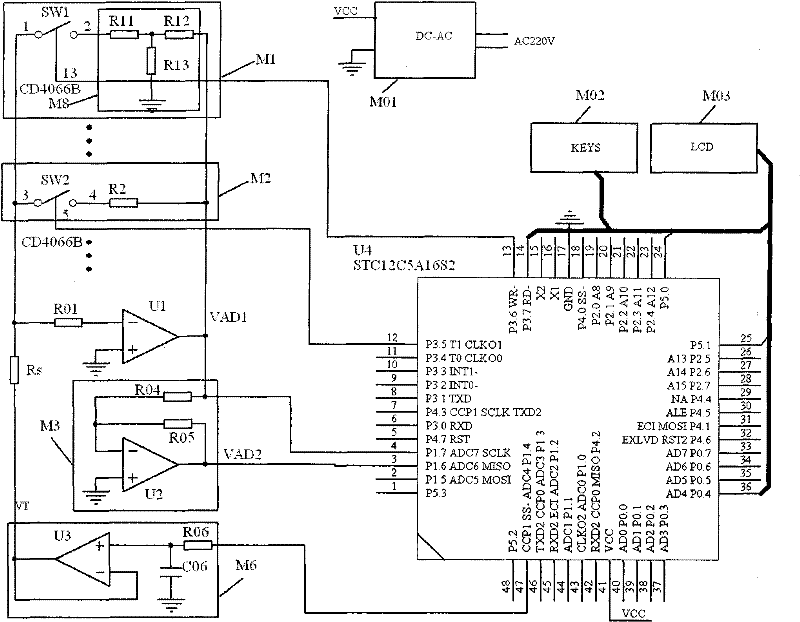

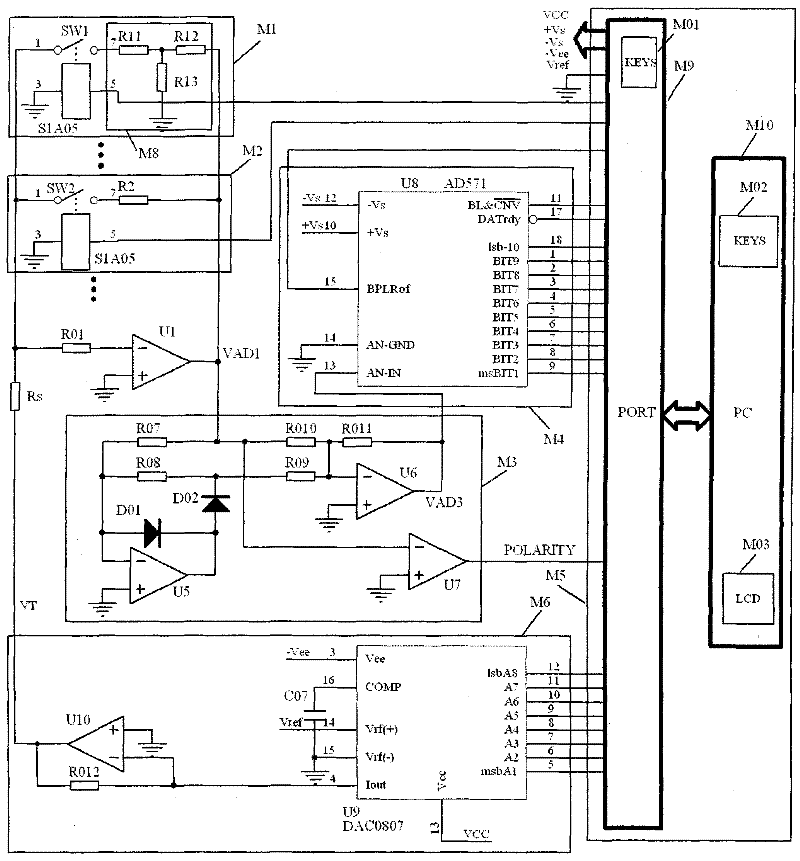

[0041] figure 2 It is a typical implementation case of a sensor resistance measuring instrument and method of the present invention, as follows:

[0042] (1) This program is implemented with an ordinary single-chip microcomputer U4 of the model STC12C5A16S2 as the core. Configurations such as the port line and the software program memory of 16KB FLASH can meet the requirements of the present invention.

[0043] (2) The test voltage source M6 is output by the operational amplifier U3, and U3 is connected as a high-impedance input voltage follower, so the test voltage source comes from a low-pass filter composed of R06 and C06, and the signal of the low-pass filter comes from a single-chip microcomputer U4 Root PWM pulse width modulation signal output port line P1.4. VT is used as the input signal voltage of the test sensor resistance, and the size of the test voltage source is controlled by the single-chip microcomputer U4 through the pulse width modulation signal. PWM is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com