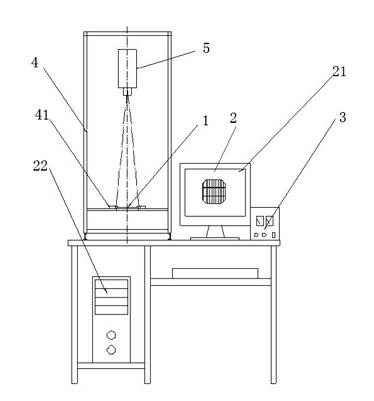

Detection device for defective products of solar cells

A technology of solar cells and detection devices, which is applied in non-contact testing, single semiconductor device testing, etc., can solve problems such as fill factor reduction, P-N junction damage, battery parallel resistance reduction, etc., to reduce incidence and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

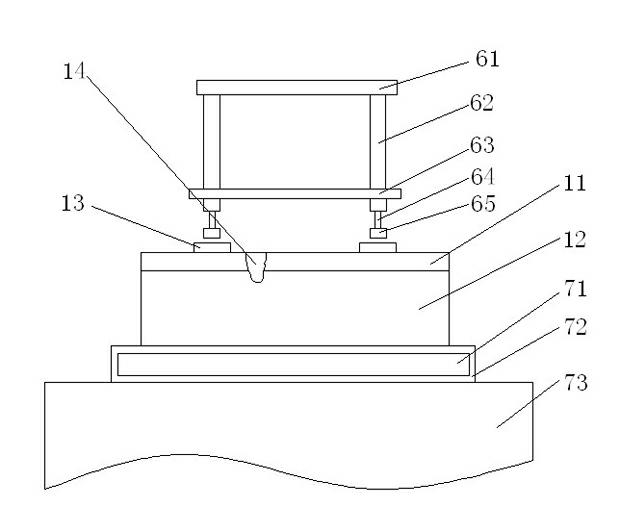

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

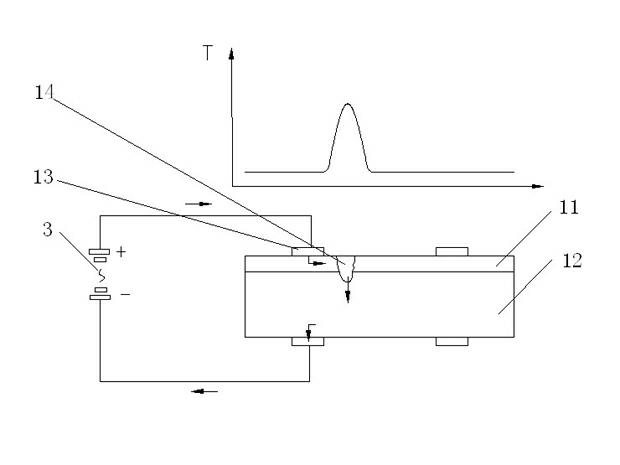

[0023] The detection principle of defective solar cells: The solar cell 1 includes an N zone 11 and a P zone 12. The interface between the N zone 11 and the P zone 12 forms a space charge zone called a PN junction 13. In the absence of light, apply a reverse voltage to the PN junction 13 (the N area 11 is connected to positive, and the P area 12 is connected to negative). At this time, a reverse current will be generated, and most of the reverse current is from the damage point of the PN junction 13 When the current flows through it, heat will be generated, so that the temperature at the point where the PN junction 13 is damaged will increase.

[0024] Use the infrared imager 5 to detect the heat generated by the temperature, and the color of the image displayed on the screen and the hot spot tracking display function can determine the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com