Uniformity compensation device applied to large field-of-view montage illumination

A compensation device and a uniformity technology, applied in the field of large-scale integrated circuit manufacturing, can solve the problem that the uniformity of the unit illumination field of view cannot be guaranteed while meeting the requirements, etc., and achieve the effects of good illumination uniformity and high illumination uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

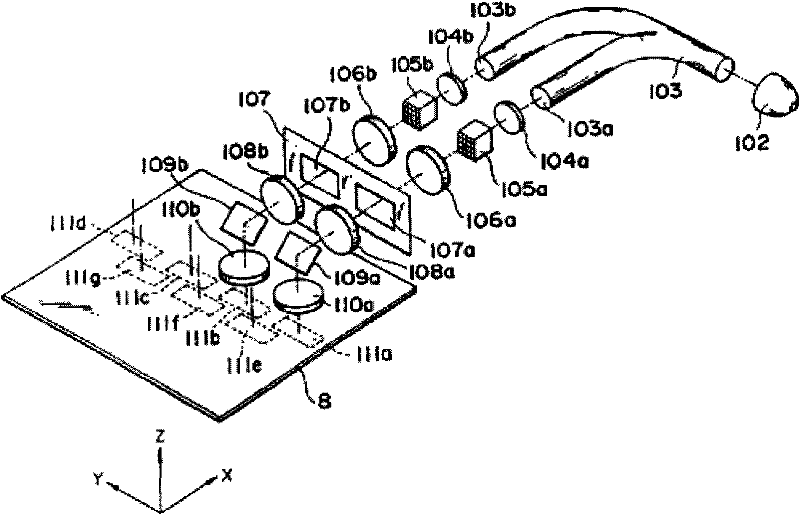

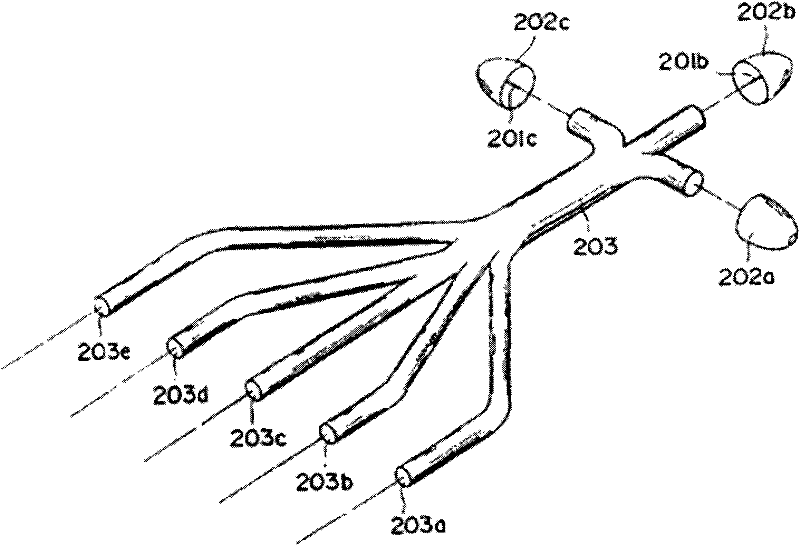

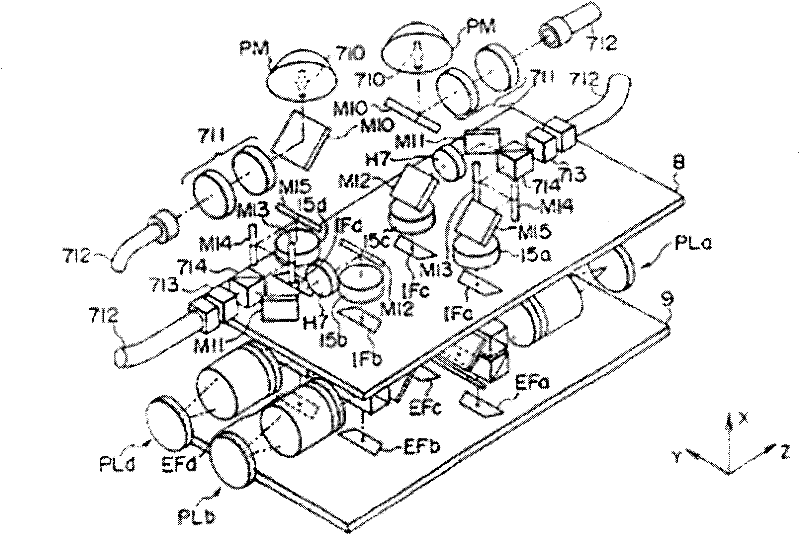

[0030] Such as Figure 4 Shown is the first embodiment of the uniformity compensation device for large-field splicing illumination provided by the present invention, which uses quartz rods or microlens arrays to homogenize the light before it enters the splitting optical fiber. In this implementation, the ultraviolet light emitted by the mercury lamp light source 1 is sequentially concentrated by the ellipsoidal reflector 2 , and uniformly modulated by the microlens array 3 and the quartz rod 4 . The uniformly modulated ultraviolet light enters the splitting optical fiber 5 and is divided into at least two paths. A detector (not shown in the figure) is placed at the light outlet of the relay lens 7 to obtain a signal of substrate illumination uniformity, and the signal is transmitted to the feedback controller 6, and the position of the mercury lamp is adjusted according to the signal.

[0031] The uniformity compensation device sequentially includes along the light transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com