High-impedance combined-type transformer

A combined transformer and transformer technology, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems affecting the development of the power industry, difficult to transport to substations, complex insulation structures, etc. The effect of low difficulty, simple disassembly, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the high impedance combined transformer of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

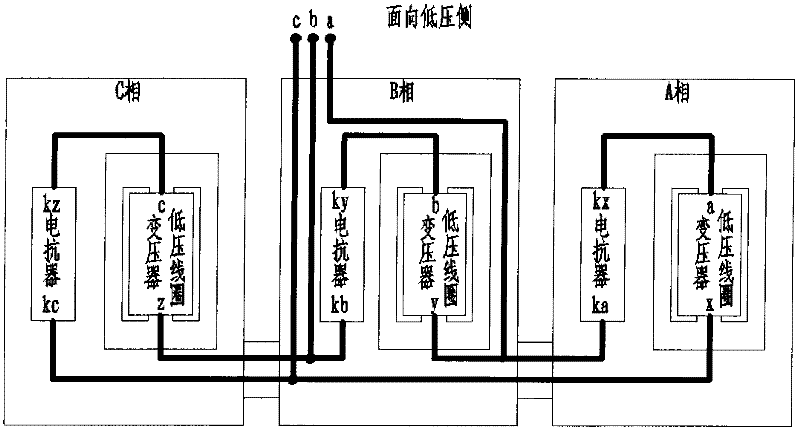

[0022] Such as image 3 As shown, in this embodiment, the high impedance combined transformer includes three single-phase transformers and three transformer tanks. The three single-phase transformers are respectively placed in three transformer tanks, and the three single-phase transformers are combined to form one Three-phase transformer. Wherein, the body structures of the three single-phase transformers are the same, and the oil tanks of the three transformers are connected to each other through corrugated pipes, so that the oil circuits in the oil tanks of the three transformers are connected.

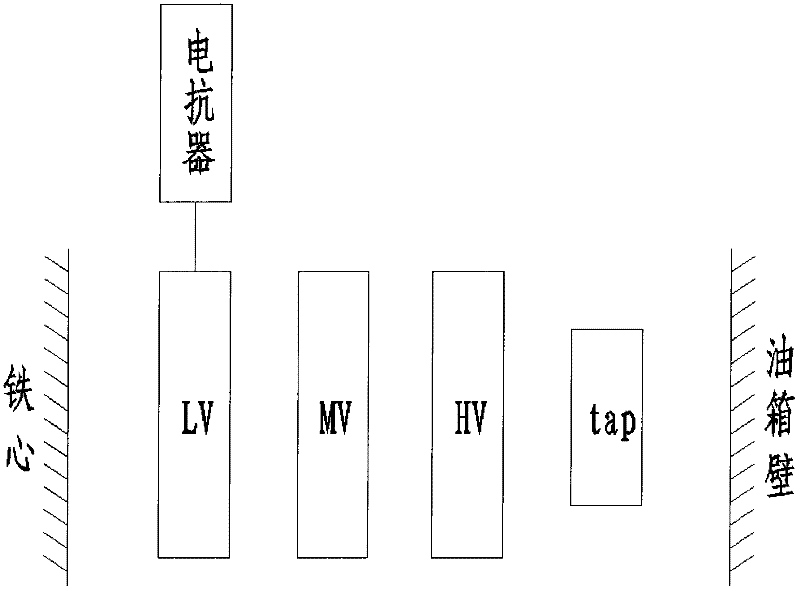

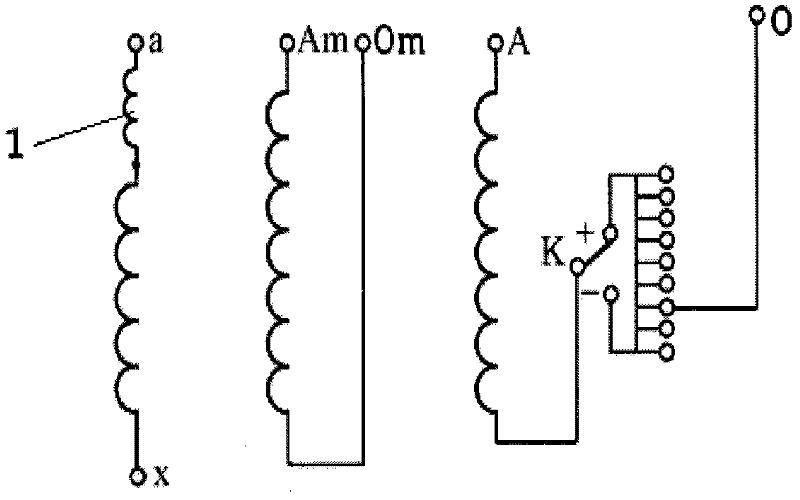

[0023] Such as figure 1 As shown, in the three-phase transformer, each phase transfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com