Electrical motor for mixed power vehicles

A technology for hybrid electric vehicles and motor housings, which is applied in the manufacture of motor generators, electric components, electrical components, etc., and can solve the problems of reducing motor torque density, low cooling efficiency of rotors, and reducing motor circumferential force torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

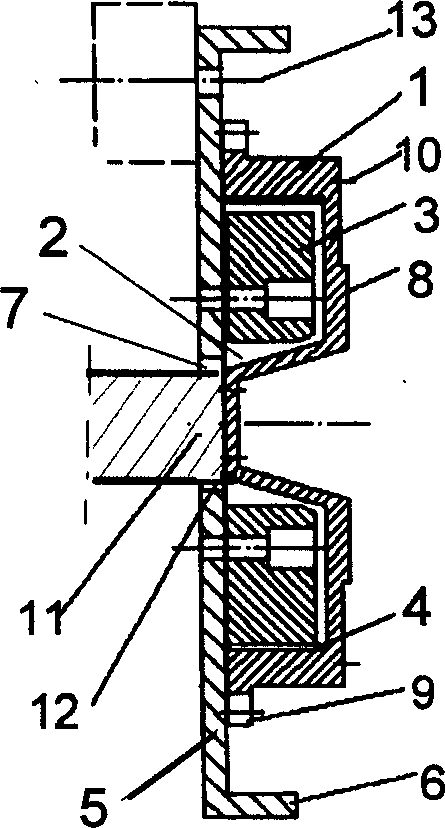

[0017] Such as figure 1 , figure 2 As shown, a motor for a hybrid electric vehicle includes a rotor 1 composed of a permanent magnet 4 and an iron core, and a stator 3 whose coils are Y-connected and connected to an inverter circuit. The rotor 1 has an E-shaped radial section, and the stator 3 is placed in the annular groove 2 of the rotor 1 , and a motor housing 5 connected with the rotor 1 is provided on one side of the notch of the rotor annular groove 2 . The motor housing 5 has a circular cylindrical body 6 protruding from the rotor 1 side along its radial end face, and a perforation 7 passing through the engine crankshaft 11 is provided at the axial position of the motor housing 5 . The engine crankshaft 11 is coupled to the rotor end face 12 via the bore 7 . The axial outer side of the ring groove 2 of the rotor 1 is provided with a friction surface 8, which is connected according to the structural type of the clutch, and its radial outer side is provided with a rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com