Differential pitch pole piece and power battery adopting same

A power battery and pole piece technology, which is applied in the direction of secondary batteries, battery pack parts, non-aqueous electrolyte battery electrodes, etc., can solve the problems of large volume of elliptical batteries, difficulty in product quality control, and reduction of current impedance, etc., to achieve internal resistance Effect of small size, volume reduction and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

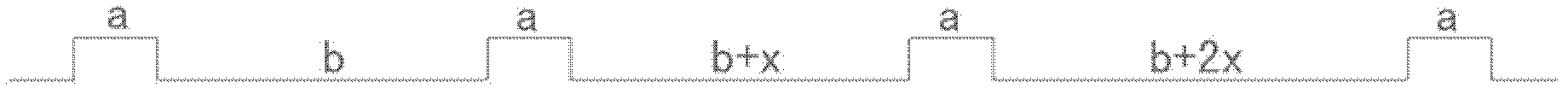

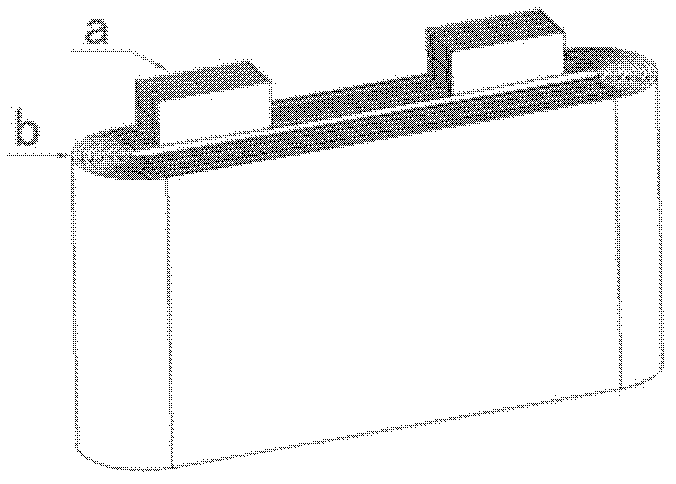

[0020] Such as figure 1 , 2 As shown, the differential pitch pole piece used for power batteries includes a coated part and an uncoated part above the coated part. The uncoated part is punched at intervals to form several protrusions. The widths are equal, and the distance between two adjacent protrusions increases from front to back to form a single-difference pitch structure, and the distance between two adjacent protrusions increases sequentially in an arithmetic sequence. The thicknesses of a diaphragm, the negative plate, and the second diaphragm are respectively r1, r2, r3, and r4, and the tolerance of the arithmetic sequence is 2kπ(r1+r2+r3+r4), wherein, k≥1, in a theoretical state, When fully fitting and winding, k should be equal to 1. In the actual winding process, due to the difference in tightness, k will be slightly greater than 1. Of course, in order to ensure the effect of winding, the range of adjustment coefficient k is generally 1≤k ≤1.2. After winding the...

Embodiment 2

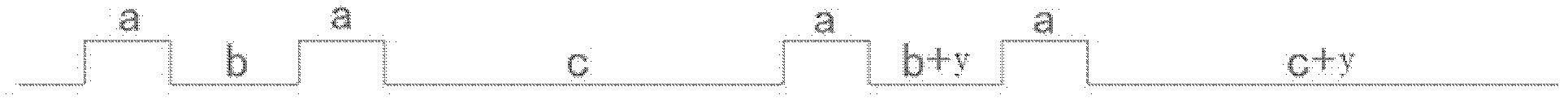

[0023] Such as image 3 , 4As shown, the pole pieces with different pitches for power batteries include coated parts and uncoated parts. The uncoated parts are punched at intervals to form several protrusions. The distance between the protruding parts increases sequentially from front to back to form a double-difference pitch structure, and the distance between the first group of spaced protruding parts increases sequentially in the first arithmetic sequence, and the distance between the second group of spaced protruding parts The spacing of the interval increases in turn into the second arithmetic sequence, and the thicknesses of the positive plate, the first diaphragm, the negative plate, and the second diaphragm are respectively r1, r2, r3, r4, and the first arithmetic sequence and the second arithmetic sequence The tolerances are all kπ(r1+r2+r3+r4), where k≥1, under theoretical conditions, k should be equal to 1 when fully fitted and wound. In the actual winding process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com