Modularized T-type microwave switch

A microwave switch and modular technology, which is applied to waveguide-type devices, electrical components, circuits, etc., can solve the problems of complicated assembly and debugging, reduced product reliability, and poor anti-shock and vibration resistance of long-piece compression springs. performance, improved vibration and shock resistance, and the effect of increasing batch production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

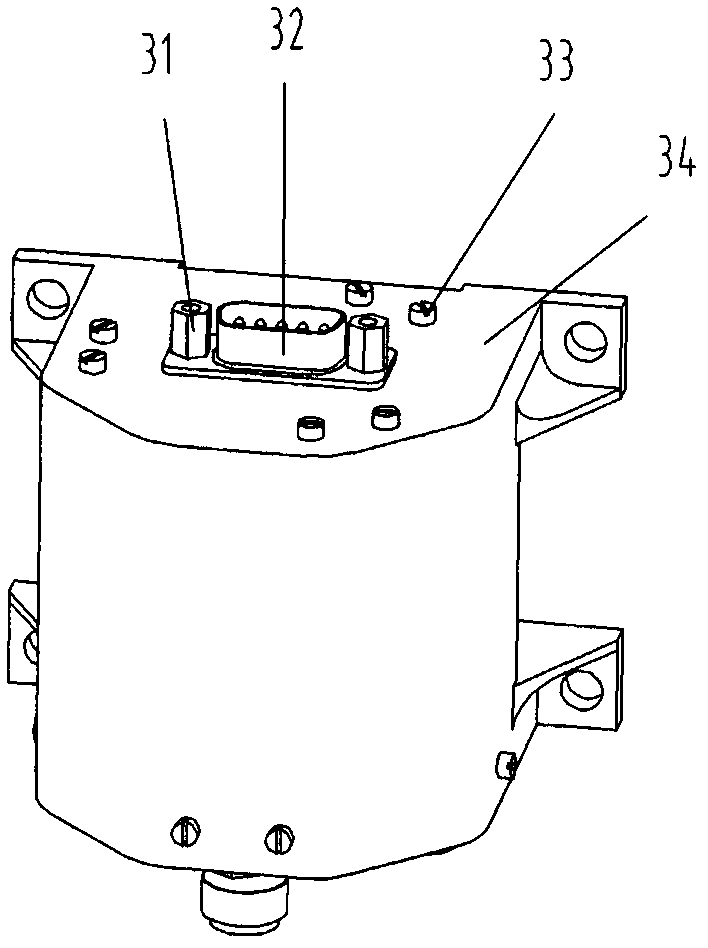

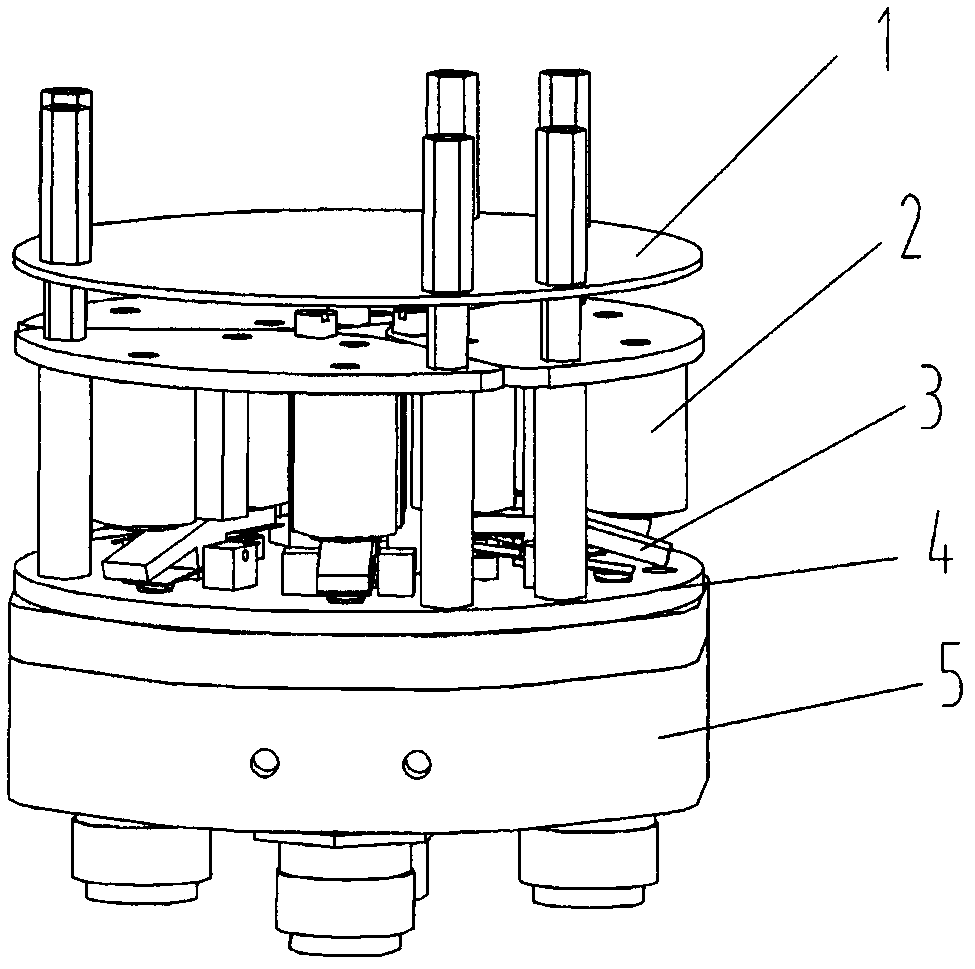

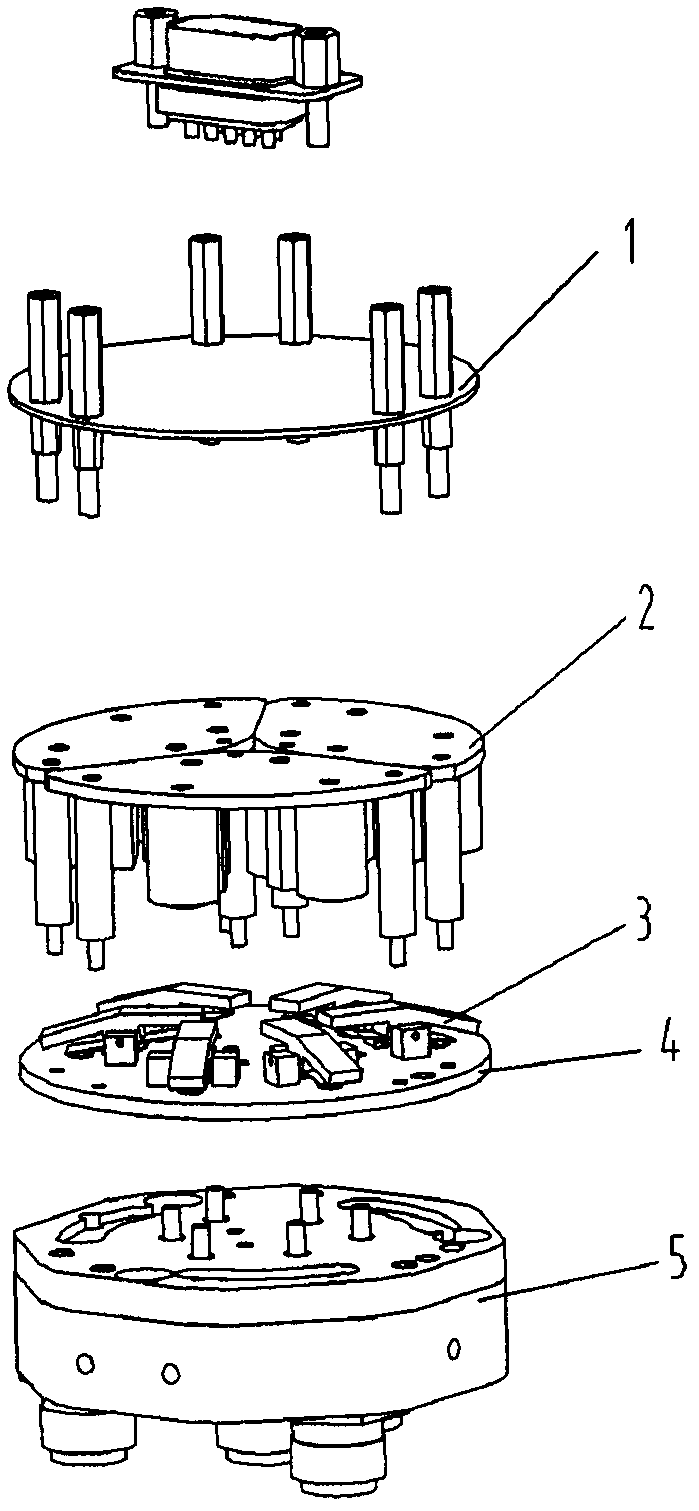

[0025] Such as figure 1 , 2 , 3, the modular T-type microwave switch of the present invention includes a circuit board group 1, an electromagnetic group 2, an armature group 3, an armature cover group 4, a guide system 5, a housing 34 and a d-sub connector 32. The circuit board group 1 is fixed above the electromagnetic group 2, the electromagnetic group 2 is fixed on the upper part of the armature cover plate group 4, the armature group 3 is fixed on the cover plate 16 through the installation shaft 18, and the armature cover plate group 4 is fixed on the guide system 5. The housing 34 is fastened to the base 29 of the guide system 5 by screws 33 , nuts 6 . The d-sub connector 32 is fastened to the housing 34 by mounting screws 31 .

[0026] Such as Figure 4 As shown, in the circuit board group 1, nuts 6 and first studs 8 are used to fix the circuit board 7 above the electromagnetic group 2, connected to the d-sub connector 32 through flying leads, and the control signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com