Rectangular wire spring filtering socket

A technology of rectangular wires and sockets, which is applied in the direction of electrical components, coupling devices, high-frequency structural connections, etc., can solve the problems of unsatisfactory use requirements, unstable contact resistance, and easy occurrence of transient breaks, etc., and achieve high practical value and electrical Excellent contact performance and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

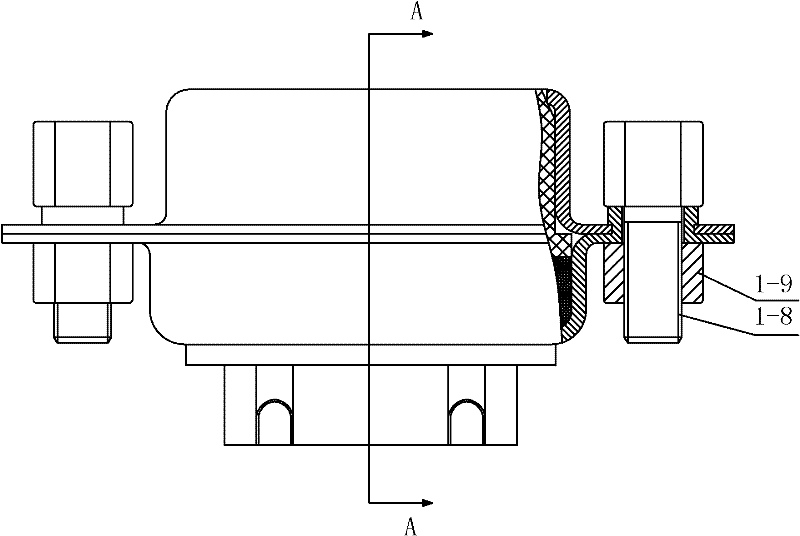

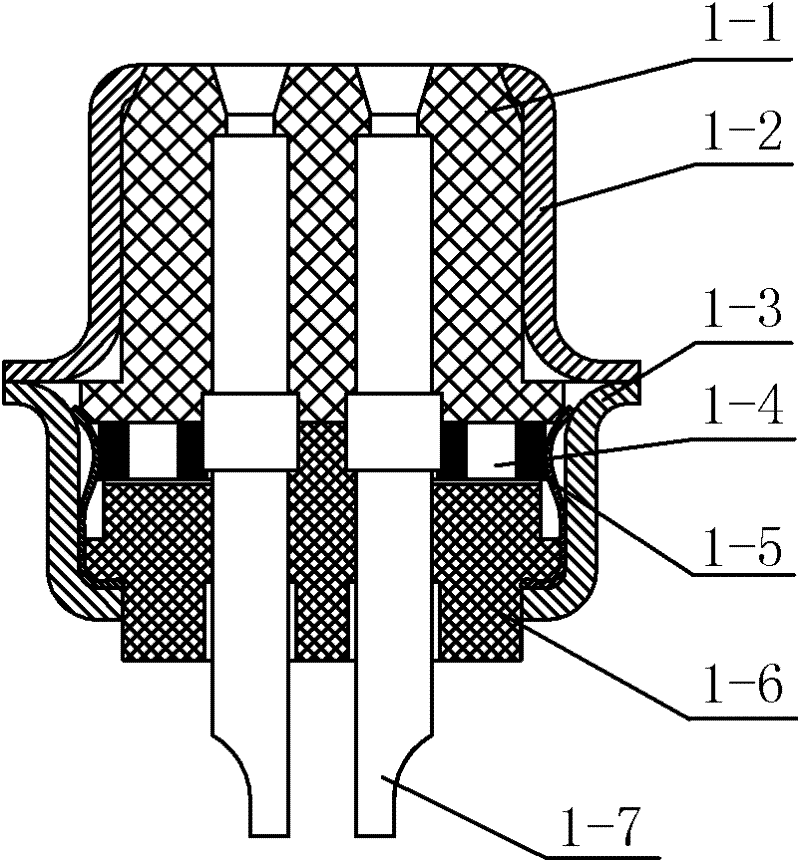

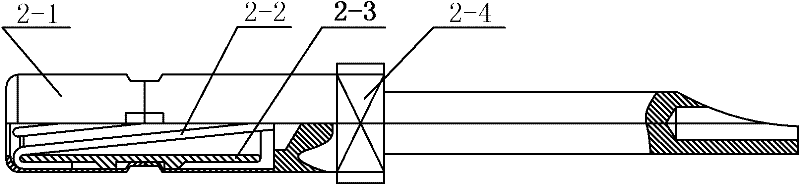

[0024] like figure 1 and 2 The shown rectangular wire spring filter socket includes an upper socket mounting plate 1-1 and a socket lower mounting plate 1-6 arranged below the socket upper mounting plate 1-1, and the socket upper mounting plate 1-1 has an outer buckle The socket upper shell 1-2 matched with it is installed, the socket lower mounting plate 1-6 is externally buckled with the socket lower shell 1-3 matched with it, the socket upper shell 1-2 and the socket Both ends of the lower housing 1-3 are fixedly connected, and a capacitor filter board 1-4 is embedded between the socket upper mounting plate 1-1 and the socket lower mounting plate 1-6, and the socket lower mounting plate 1-6 An elastic reed 1-5 is arranged between the socket lower housing 1-3, and a wire spring socket contact 1-7 is fixedly installed between the socket upper mounting plate 1-1 and the socket lower mounting plate 1-6, The wire spring socket contact 1-7 includes a front cover 2-1 and a rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com