Electric appliance control box

An electrical control box and splint technology, applied in electrical components, electrical equipment shells/cabinets/drawers, cooling/ventilation/heating renovation, etc., can solve the problem of uneven heat dissipation of the box, and achieve the effect of uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

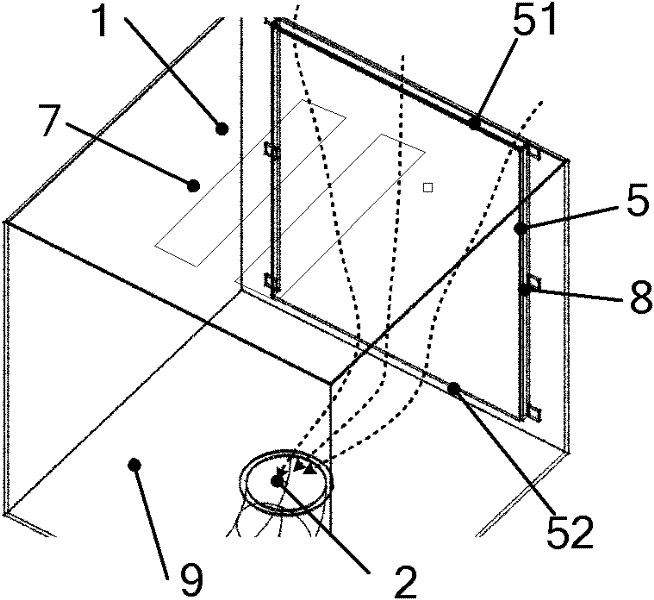

[0020] like figure 1 As shown, the electrical control box of the present invention includes a first air inlet 1 arranged on the first side wall 7, an air outlet 2 arranged on the second side wall 9, and the air outlet 2 is connected with a suction pipe 3 , the suction pipe 3 is connected with a suction device 4, and also includes a splint 5, the splint 5 is installed in parallel on one of the remaining side walls, and a gap 8 is left between the splint 5 and the remaining side wall One end of the slit 8 is provided with a second air inlet 51, the second air inlet 51 is close to the first air inlet 1, and the other end of the slit 8 is provided with an air guide 52 capable of flowing to the air outlet 2, the The air guiding port 52 is close to the air outlet 2 . Wherein the suction device 4 is a blower fan.

Embodiment 2

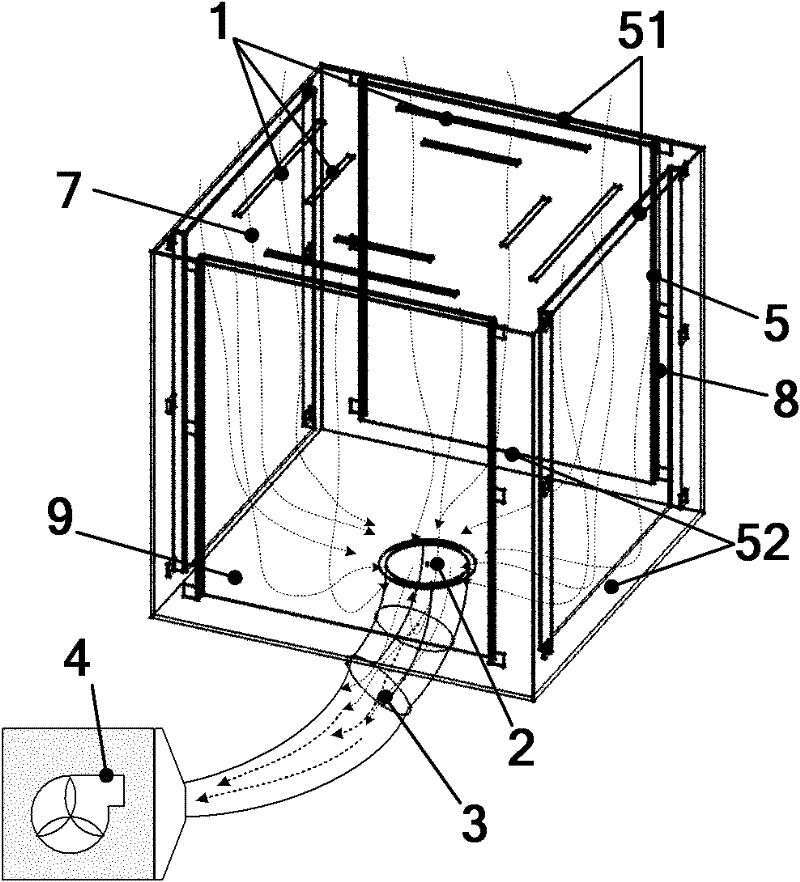

[0022] like figure 2 As shown, this embodiment 2 is improved on the basis of embodiment 1, and its distinguishing technical feature is that it includes a plurality of splints 5, and the splints 5 are installed in parallel on multiple surfaces of the remaining side walls. That is to say, the difference between Embodiment 2 and Embodiment 1 is the number of splints 5 installed.

[0023] In the above two embodiments, the second air inlet 51 , the slit 8 , the air guide 52 , and the air outlet 3 constitute the second heat dissipation air duct. During use, electrical components are installed on the side wall of the splint 5 of the electrical control box. Start the suction device 4, and the new constant temperature air is sucked from the second air inlet of the second heat dissipation air duct, and flows through the side wall of the splint 5 (that is, the splint with electrical components) of the heat generating part through the gap 8 and the air guide port 52 and the box. The si...

Embodiment 3

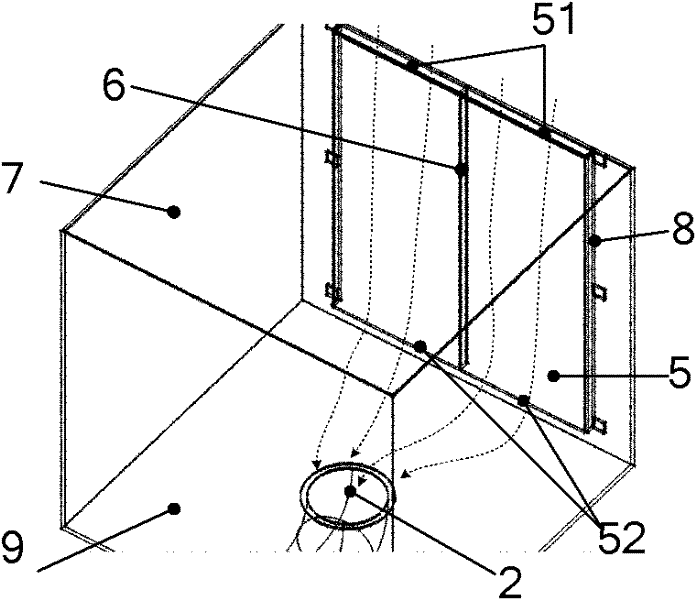

[0027] like image 3 As shown, Embodiment 3 is improved on the basis of Embodiment 1. Its heat dissipation principle is the same, and the difference lies in the structural change. Specifically, it is vertically arranged between the splint 5 and the remaining side wall of the electrical control box. There is a rib 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com