Bean curd machine

A tofu machine and soybean milk technology, which is applied in cheese substitutes, household utensils, food preparation, etc., can solve the problems of tofu pollution, and achieve the effects of saving time, simple structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

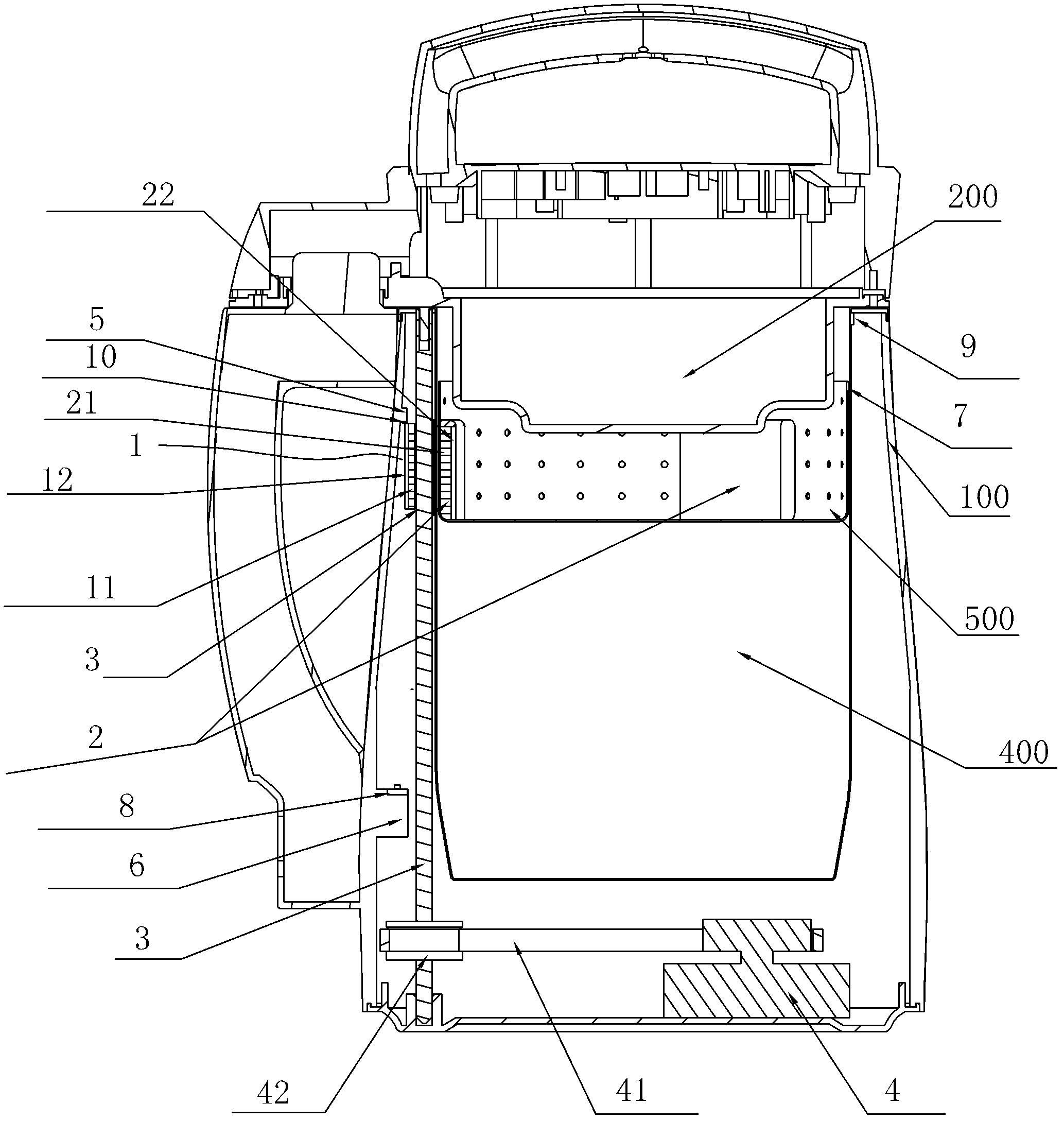

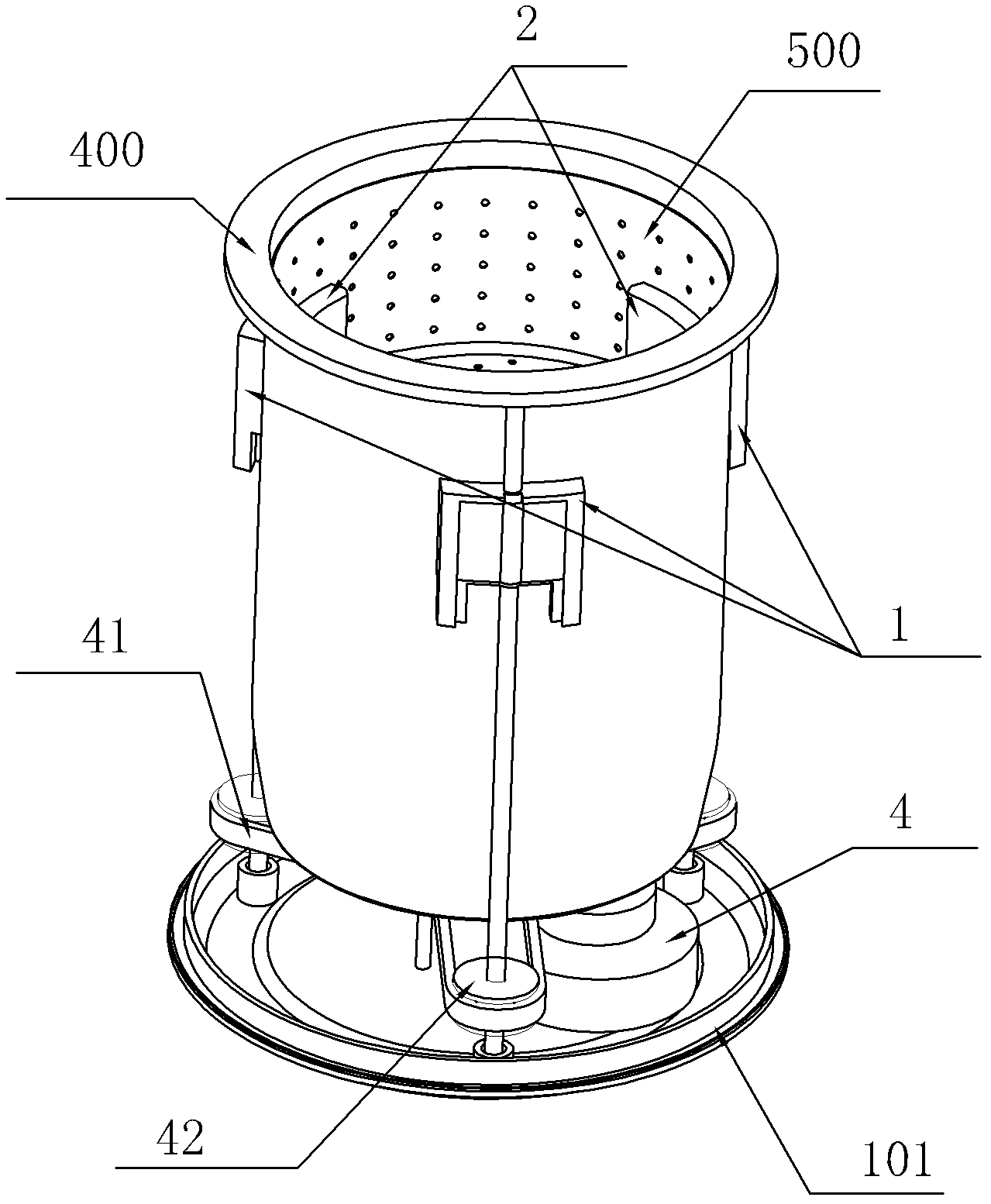

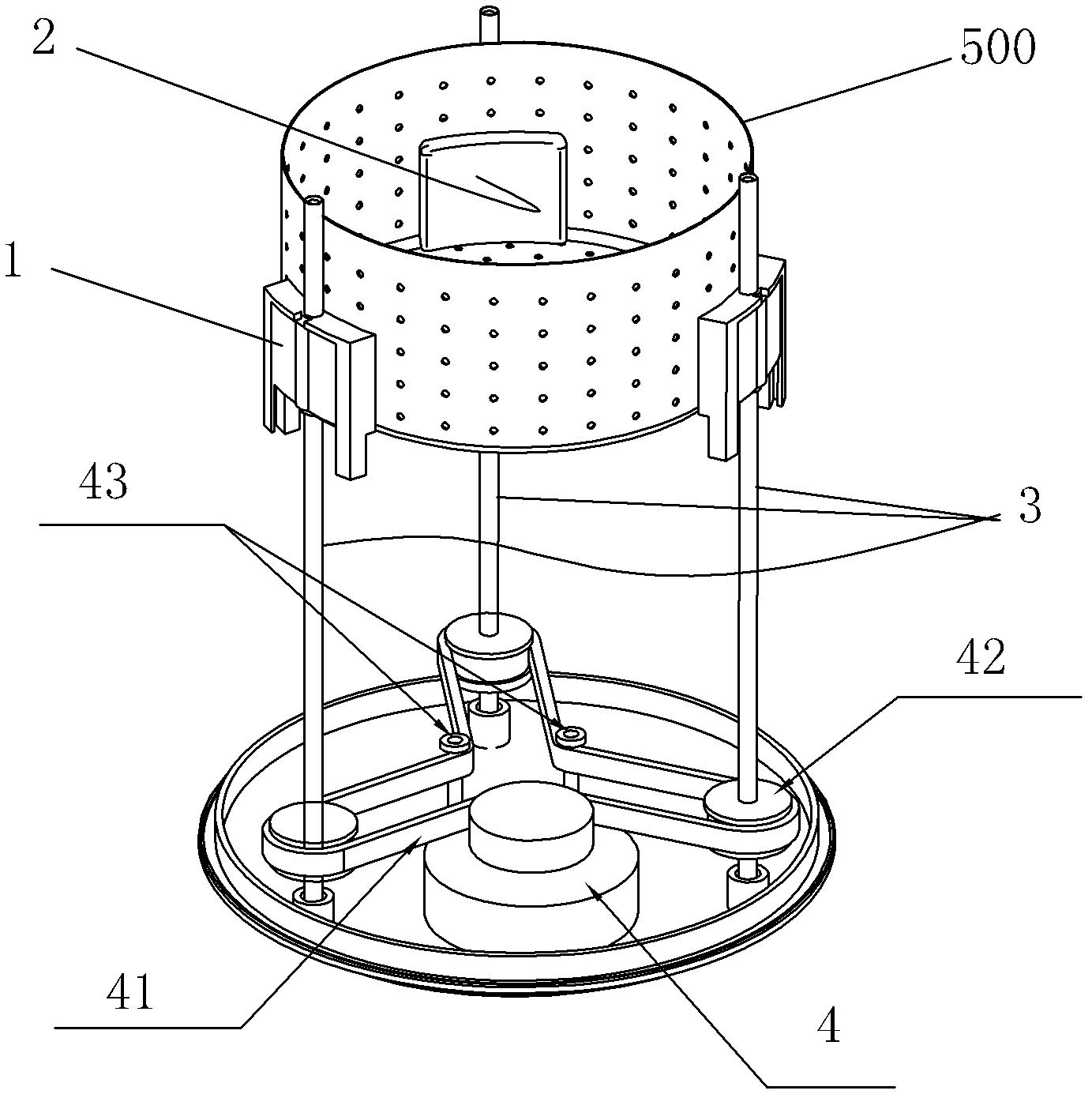

[0024] Such as figure 1 As shown, the bean curd machine of the present invention includes a head 200, a body 100, a soybean milk bucket 400 and a mesh screen 500, the screen 500 is arranged in the soybean milk bucket 400, a control circuit is arranged in the head 200, and the operation control buttons of the tofu machine Located on the top surface of the machine head 200, the coagulant box 300 for storing the coagulant for point pulp is arranged on the machine head 200, and the outlet of the coagulant box 300 is connected with the soybean milk bucket 400 which is arranged in the body 100 and is clamped on the machine head 200 In the same way, the mesh screen 500 is placed in the soybean milk bucket 400, and its upper end is socketed and adsorbed on the lower part of the machine head 200 through the elastic protrusions or magnets arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com