Preparation method for instant release type cigarette mouth rod

A technology for cigarettes and mouthpieces, applied in the manufacture of paper cigarettes, etc., can solve the problems of inability to achieve instant release and inability to guarantee moisture preservation, and achieve the purpose of removing water-soluble harmful substances, increasing the overall moisturizing and aroma of cigarettes, and improving sensory comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Dissolve sodium alginate in deionized water at a ratio of 0.5:99.5 and stir to suspend evenly;

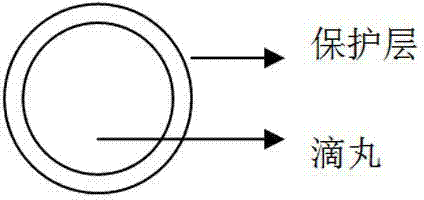

[0028] 2. Drop the suspension prepared in 1 into the cross-linking solution by drop method, so that the surface substance is rapidly calcified to form a protective film, which wraps the mixed solution of sodium alginate and water to obtain the drop pill;

[0029] 3. After the dripping pill is formed, take it out after 30 seconds, put it in pure water, and wash away the surface cross-linking liquid;

[0030] 4. One or both of solid paraffin, polycaprolactone, polylactic acid, and polyurethane are melted by hot-melt method, placed in the coating equipment and coated on the outer surface of the dripping pill obtained in 2 according to a specific process, so that After drying, it becomes one or several layers of uniformly thick and thin functional protective layer closely adhered to the surface;

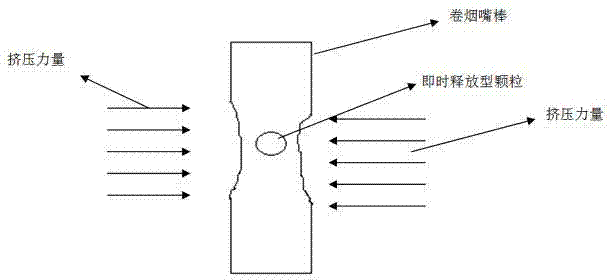

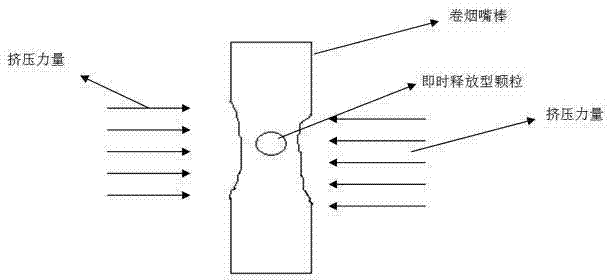

[0031] 5. Use cigarette tip forming equipment and special cigarette tip compo...

Embodiment 2

[0035] 1. Dissolve sodium alginate in deionized water at a ratio of 1:99 and stir to suspend evenly;

[0036] 2. Drop the suspension prepared in 1 into the cross-linking solution by drop method, so that the surface substance is rapidly calcified to form a protective film, which wraps the mixed solution of sodium alginate and water to obtain the drop pill;

[0037] 3. After the dripping pill is formed, take it out after 30 seconds, put it in pure water, and wash away the surface cross-linking liquid;

[0038] 4. One or both of solid paraffin, polycaprolactone, polylactic acid, and polyurethane are melted by hot-melt method, placed in the coating equipment and coated on the outer surface of the dripping pill obtained in 2 according to a specific process, so that After drying, it becomes one or several layers of uniformly thick and thin functional protective layer closely adhered to the surface;

[0039] 5. Use cigarette tip forming equipment and special cigarette tip composite...

Embodiment 3

[0043] 1. Mix ethanol and water at a ratio of 10:20;

[0044] 2. Take sodium alginate and the mixed solution obtained in 1 and suspend evenly, the ratio of sodium alginate and water is 0.5:99, stir, and suspend evenly;

[0045] 3. Drop the suspension prepared in 1 into the cross-linking solution by drop method, so that the surface substance is rapidly calcified to form a protective film, which wraps and mixes with the mixed solution of sodium alginate and water to obtain the drop pill;

[0046] 4. After the dripping pill is formed, take it out after 30 seconds, put it in pure water, and wash away the surface cross-linking liquid;

[0047] 5. Melt one or more of solid paraffin, polycaprolactone, polylactic acid, and polyurethane by hot-melt method, put it in the coating equipment and coat it on the outside of the dripping pill obtained in 3 according to a specific process Surface, make it dry to become one or several layers of evenly thick and thin functional protective layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com