Ultrasound transducer with improved adhesion between layers

An ultrasonic transducer and adhesive technology, applied in ultrasonic/sonic/infrasonic diagnosis, instruments, sonic diagnosis, etc., can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

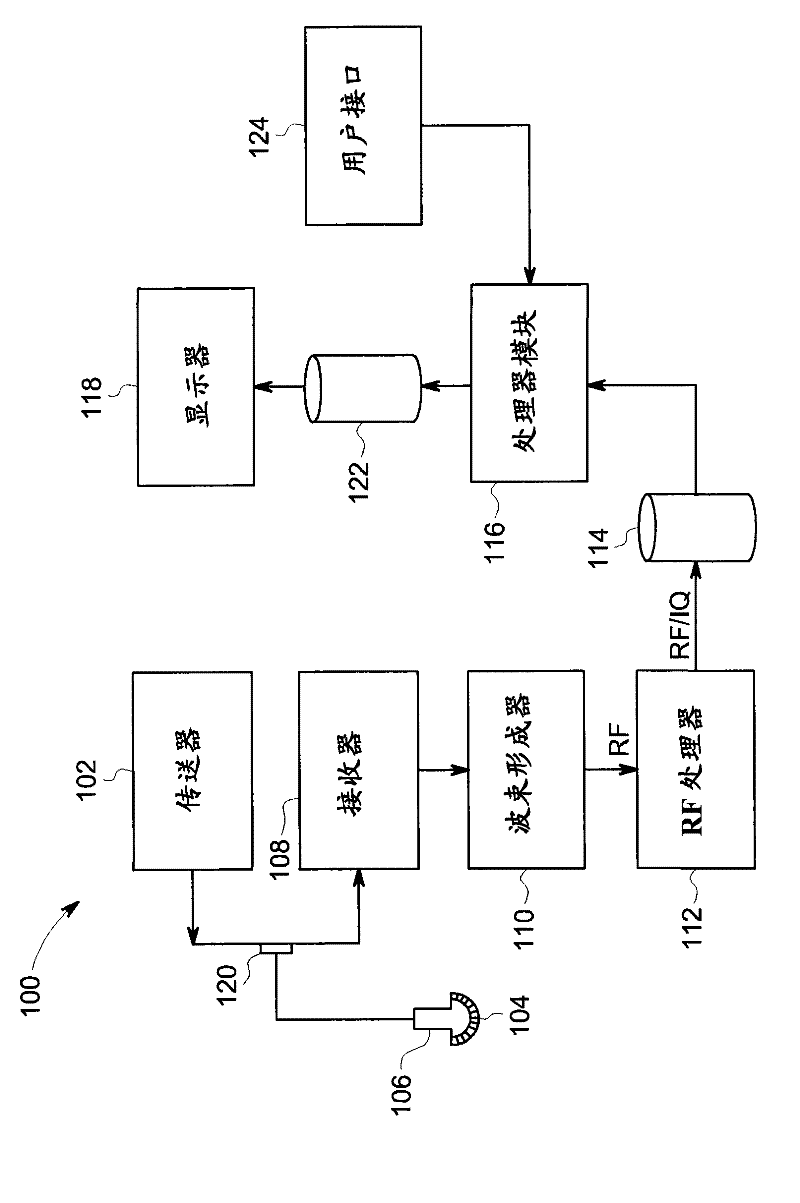

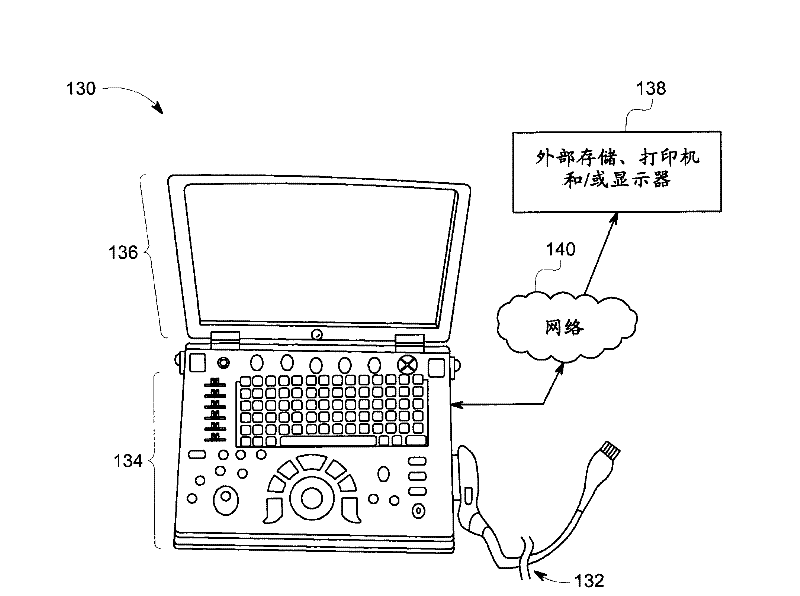

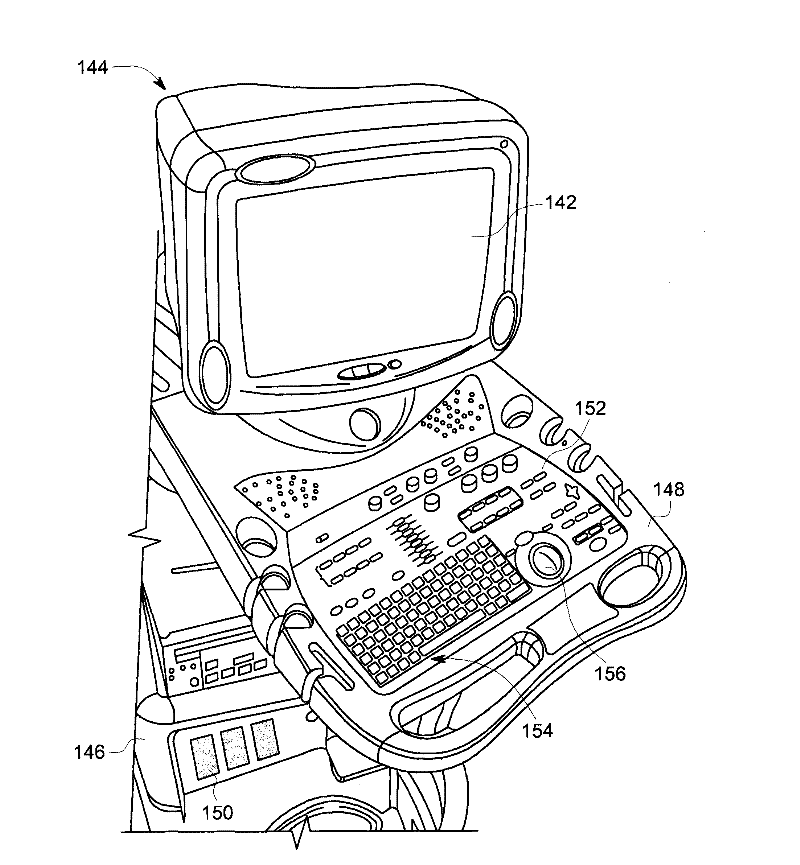

[0026] The foregoing summary, as well as the following detailed description of certain embodiments of the invention, will be better understood when read in conjunction with the accompanying drawings. In order to illustrate the invention, certain embodiments are shown in the figures. It should be understood, however, that the invention is not limited to the arrangements and instrumentalities shown in the drawings. To the extent that the figures illustrate diagrams of the functional blocks of various embodiments, the functional blocks are not necessarily indicative of the division between hardware circuitry. Thus, for example, one or more of the functional blocks (eg, a processor or memory) may be implemented in a single piece of hardware (eg, a general-purpose signal processor or random access memory, hard disk, etc.). Similarly, a program can be a stand-alone program, combined as a subroutine in an operating system, a function in an installed software package, and so on. It ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap