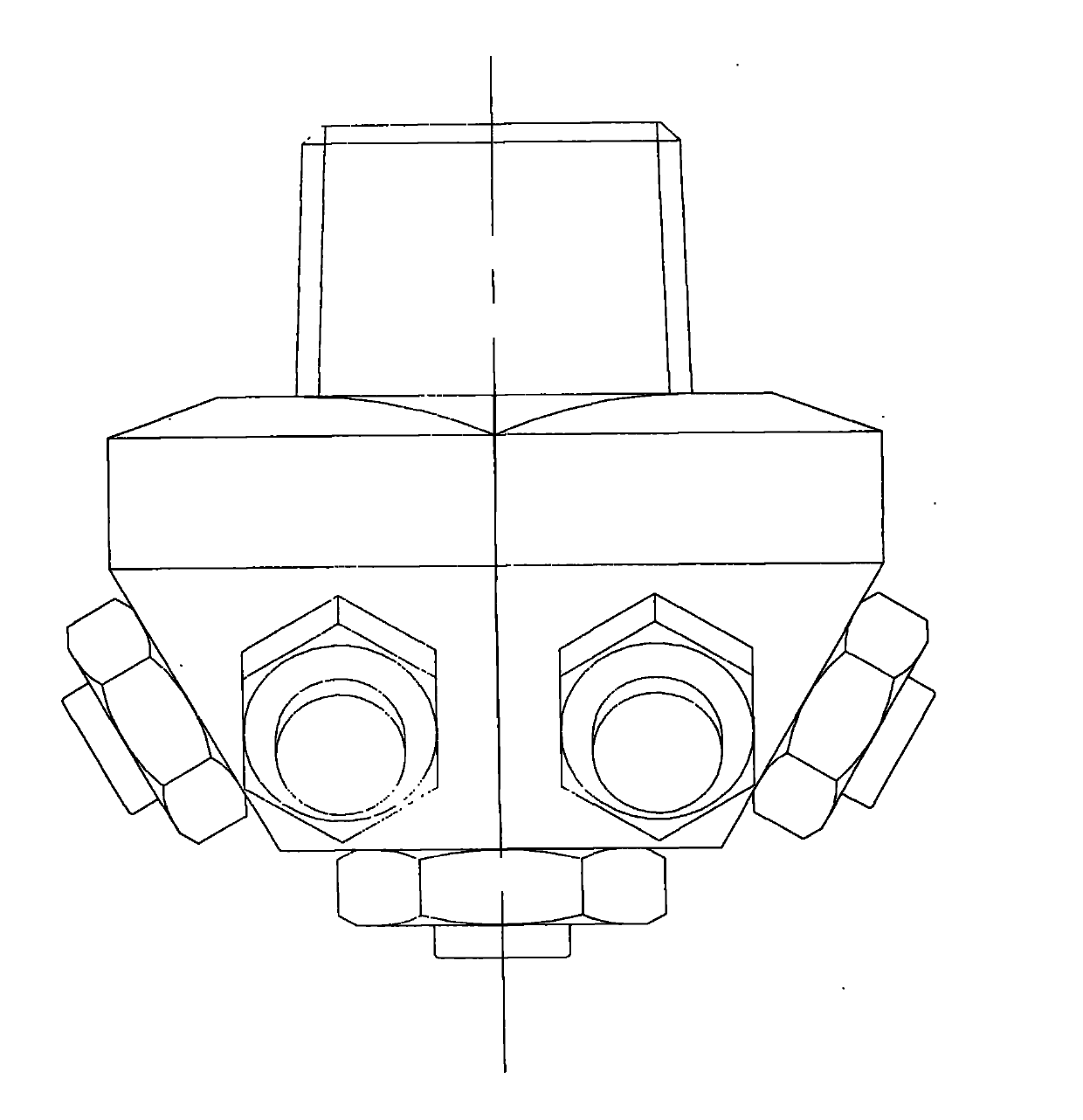

Anti-dripping fine water mist spray head

An anti-dripping and fine water mist technology, which is applied in the fields of fire fighting, fire control and fire prevention, can solve the problems of leakage, easy clogging of spray core and nozzle hole, etc., and achieve the effect of eliminating clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

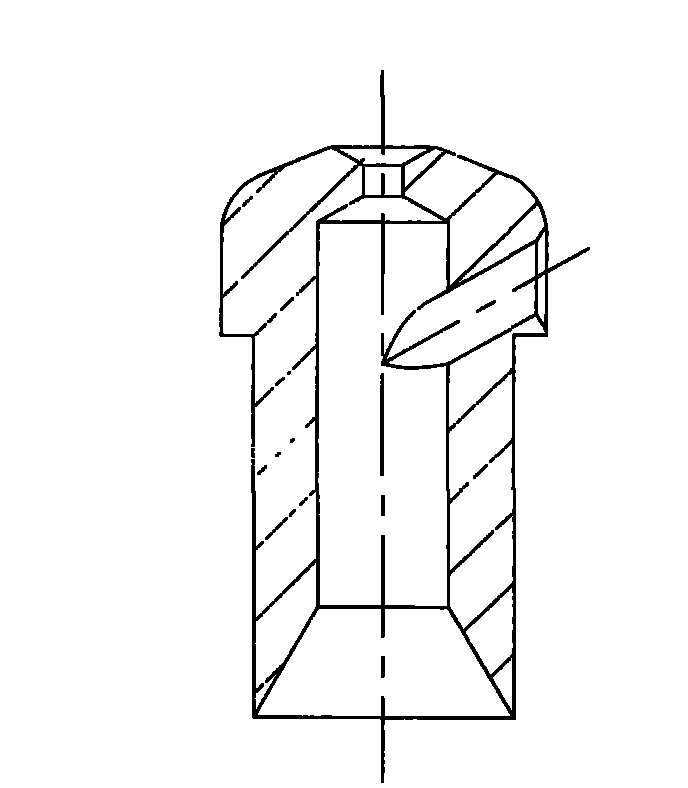

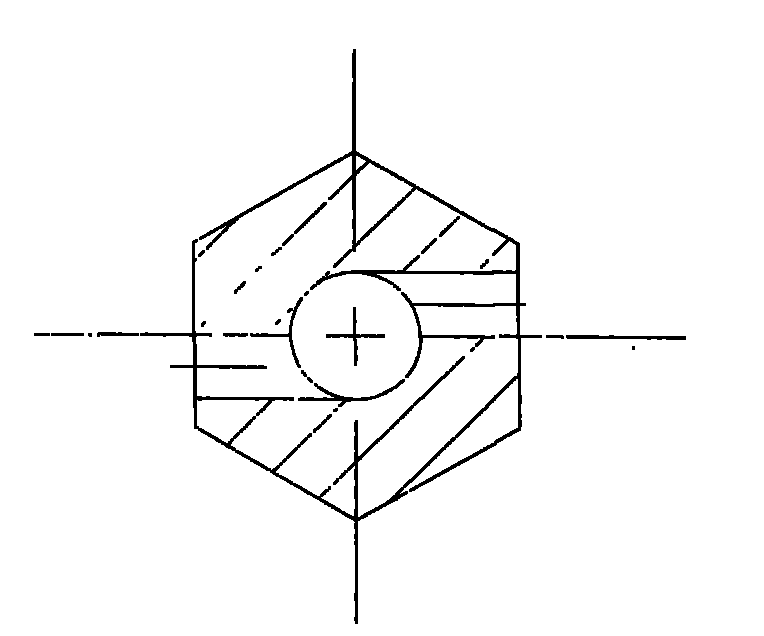

[0020] The spherical filter screen is fixed with the locking bolt in the inner passage on the water inlet side of the nozzle. One end of the spring is set on the rubber ball, and the other end is embedded in the recess of the middle nozzle; the rubber ball is pushed by the spring to move toward the water inlet, and is in circumferential contact with the conical sealing seat of the body to maintain a sealed state. The spray core is assembled in the inlet of each nozzle, and the dust cover is set on the outer circle of each nozzle. Usually, the rubber ball is in line contact with the conical sealing seat of the body under the thrust of the spring, so that the nozzle is kept in a closed and sealed state. When spraying starts, because the water pressure does not reach the predetermined pressure value, the nozzle is always in a closed and sealed state; when the water inlet pressure reaches the predetermined pressure value, the water flow pushes the spring and the rubber ball to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com