Bag type dust-collecting, energy-storing ash-removal method

A technology of bag dust removal and dust removal, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve the problems of shortening the service life of cloth bags, inability to be widely used, and high frequency of dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

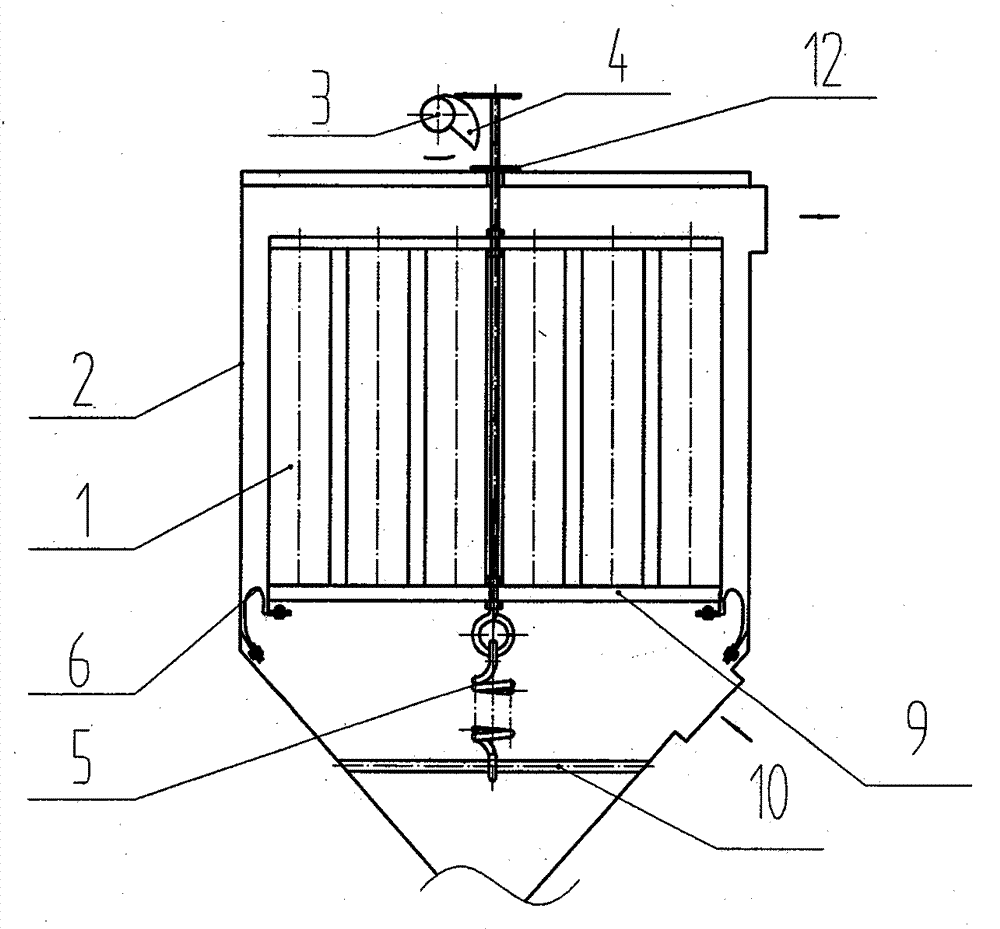

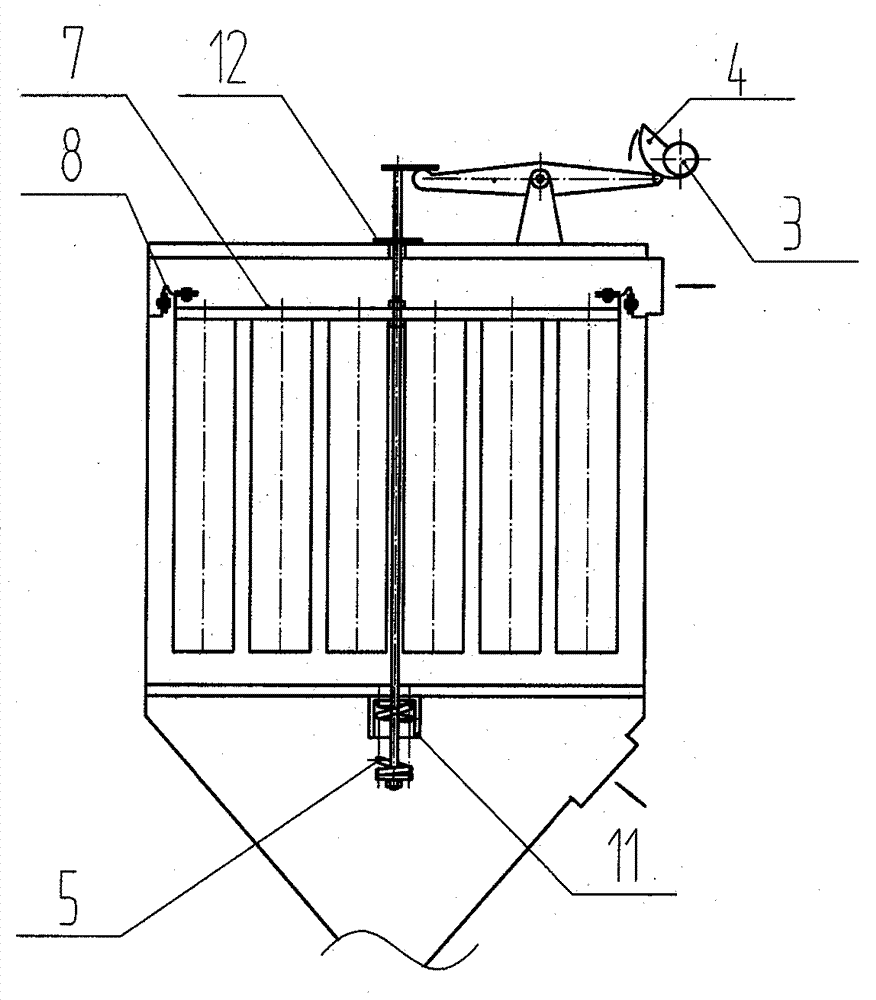

[0018] The bag dust removal and storage energy cleaning method includes the bag group 1 placed vertically in the dust collector box 2. The cleaning method is divided into two steps. The first step is to hang the bag group 1 on the top plate of the box body 2, and the lower part is equipped with The spring 5 with pre-tightening force, when the external force in the up and down direction is applied, the bag group 1 can move up and down; the second step is to design a mechanical mechanism that can gradually increase the external force to the bag group 1 and the lower spring starting from the pre-tightening force. The mechanism stores energy on the spring; when the external force is applied to a certain extent, the mechanism is suddenly released, and the bag group 1 obtains a sudden change in the energy generation speed to realize dust removal. refer to figure 1 , figure 2 .

[0019] The bag group 1 is divided into two types: the lower flower plate 9 and the bag group 1 are int...

specific Embodiment approach 1

[0025] refer to figure 1 . The bag group 1 is fixed together with the lower flower plate 9 to form a whole that can move up and down; at this time, the lower flower plate 9 is used, and the bag mouth is downward, which is an internal filter type; the lower flower plate 9 and the surrounding box 2 There is a lower cloth soft connection 6 that can separate the dusty gas from the clean gas; the bottom of the bag group 1 is provided with a lower tension spring fixed point 10 that is firmly connected to the lower part of the box body 2; The very slow main shaft 3 driven by the motor is fixedly connected with a cam 4 on the main shaft 3 . The method of use is to first apply a certain tension on the lower tension spring, which is called pre-tightening force. At this time, the bag group 1 has a tendency to move downward, but the limit plate 12 has restricted it; Rotate counterclockwise in the direction indicated by the arrow, and the cam 4 drives the whole bag group 1 to lift up slo...

specific Embodiment approach 2

[0027] refer to figure 2 . This scheme uses the upper flower plate 7, the bag mouth is upward, which is an external filter type; the upper flower plate 7 and the surrounding box 2 are equipped with an upper cloth soft connection 8 that can separate the dusty gas from the clean gas The bottom of the cloth bag group 1 is provided with a lower compression spring, and the upper part of the lower compression spring is equipped with a compression spring fixing cap 11 that is set on the spring and is fixed with the lower part of the box body. At this time, the bag group 1 has a tendency to move downward, but the limit plate 12 has restricted it; then start the deceleration motor to make the main shaft 3 rotate counterclockwise in the direction of the arrow shown in the figure, and the cam 4 presses the link Drive the whole bag group 1 to lift up slowly. At this time, the pressure on the lower compression spring gradually increases until it reaches the maximum and then suddenly rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com