Wet dedusting-desulfurization compound purification device

A compound purification and wet dedusting technology, which is applied in the direction of combined devices, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of unfavorable promotion of energy-saving and environmental protection equipment, difficulty in selecting manufacturers, and inability to meet environmental protection requirements. Improve the effect of dust removal and desulfurization, save equipment space, and strengthen the effect of dust removal and desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

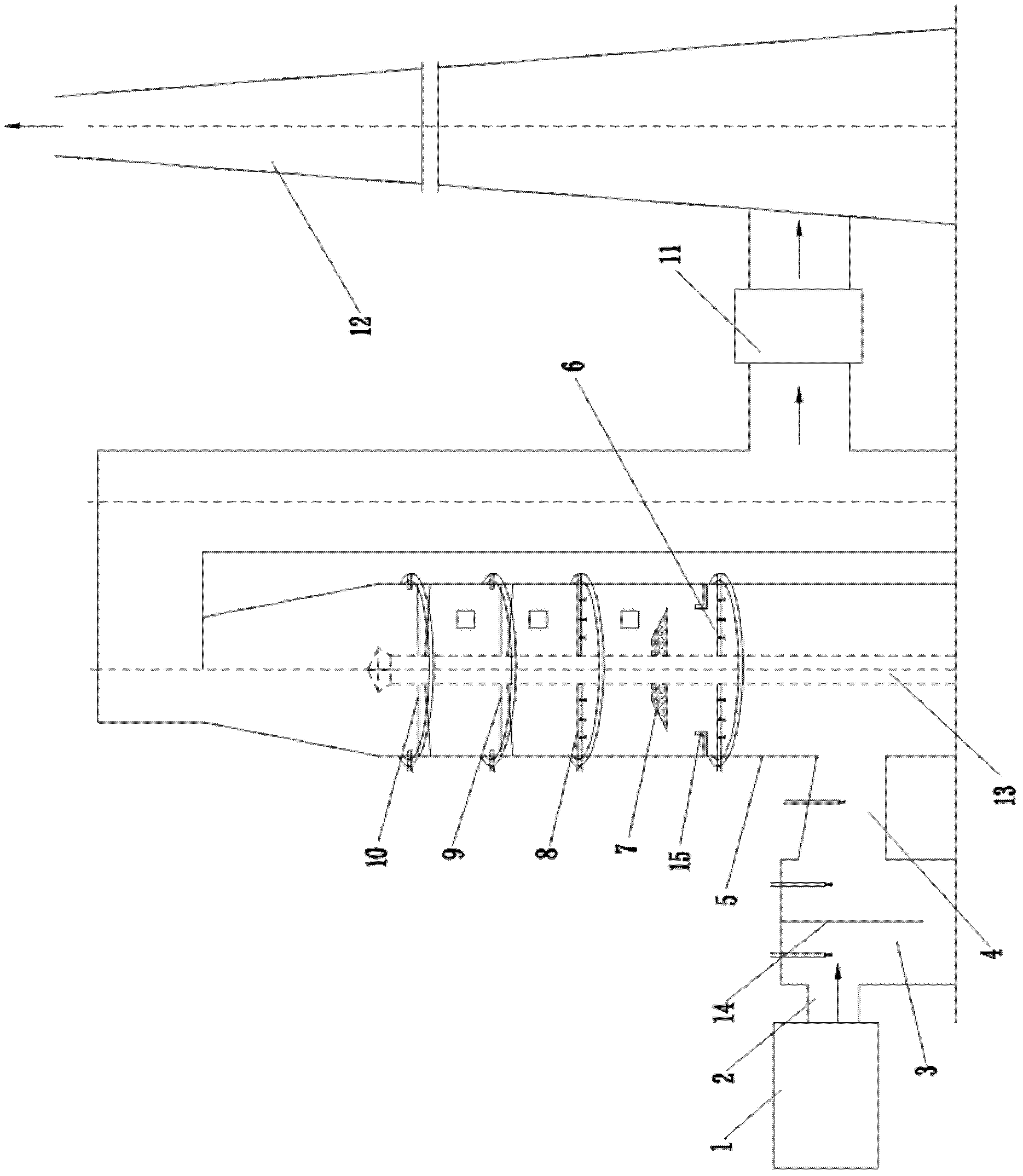

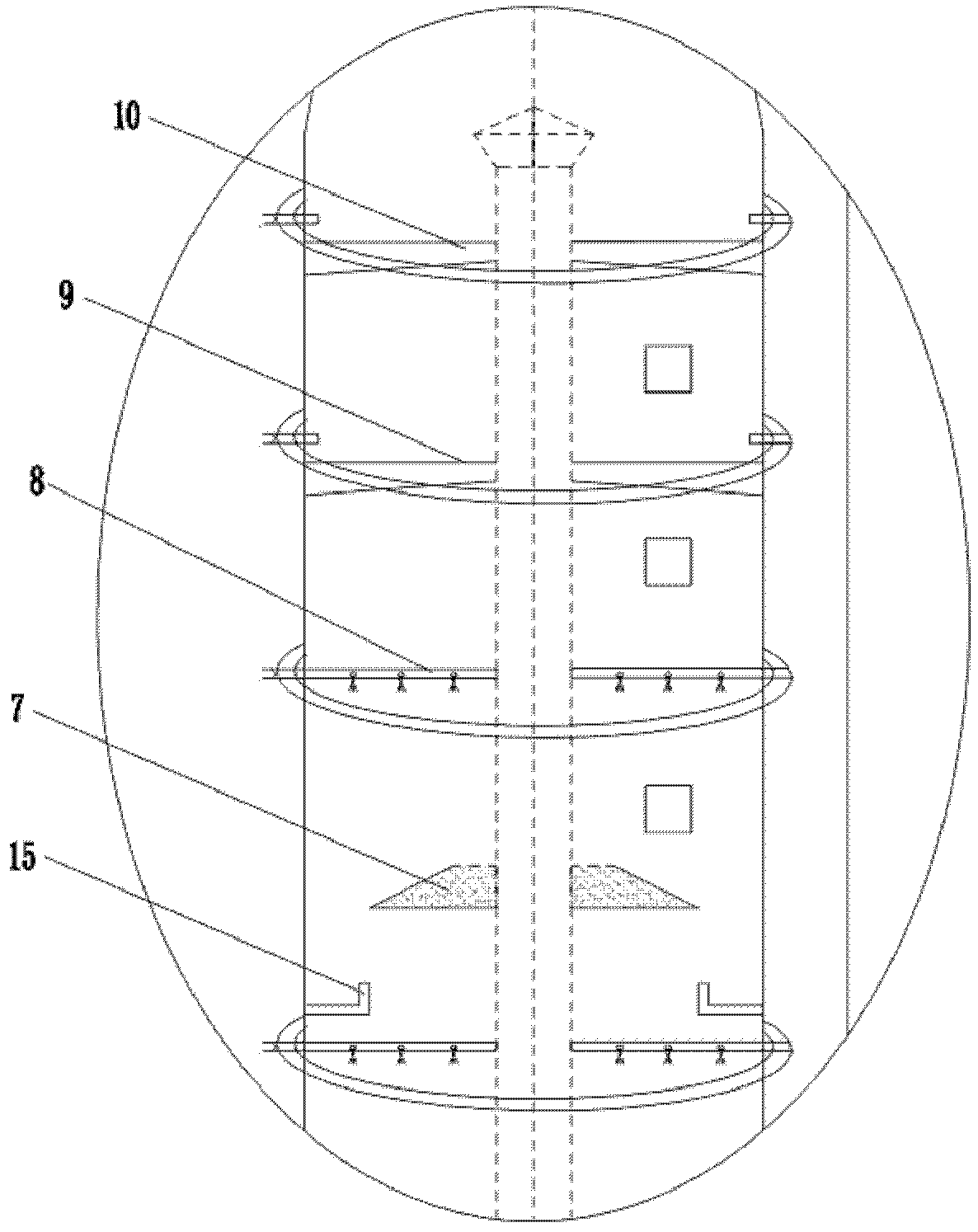

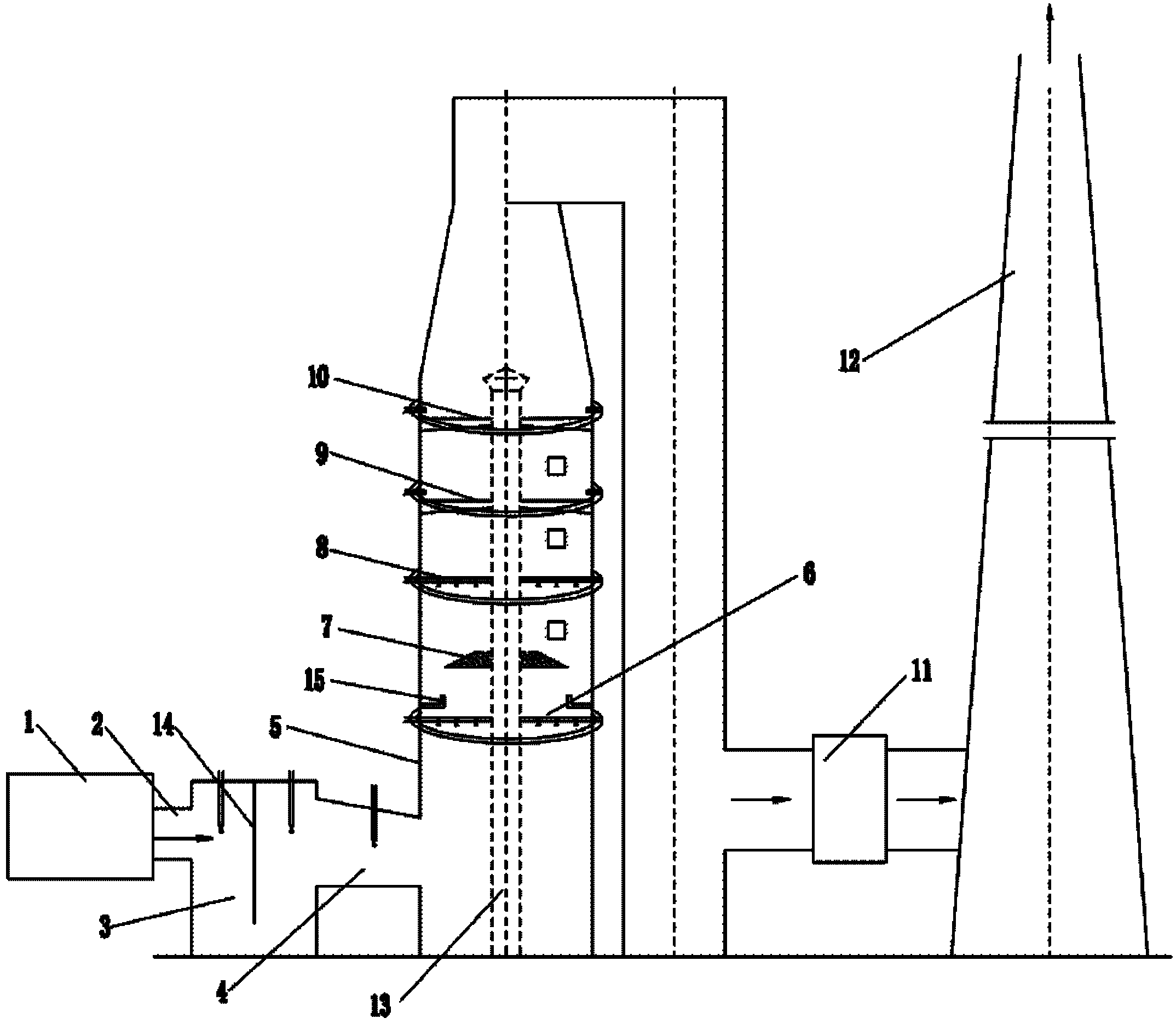

[0020] Example: see figure 1 , 2 , the wet dust removal and desulfurization compound purification device of this embodiment is to connect the flue 2, the impact type pre-dust removal desulfurizer 3, and the Venturi 4 in series at the outlet of the industrial boiler or industrial kiln 1, and connect the outlet of the Venturi to the dust removal and desulfurization composite tower The lower part of the main cylinder 5, the dust removal and desulfurization section at the lower part of the main cylinder, figure 2 As shown, a wet spray atomization layer 6, a water-avoiding separation cap 7, a spray atomization layer 8, a spray atomization swirl plate 9, a steam-water separation plate 10, and a main cylinder 5 are sequentially arranged from bottom to top in the main cylinder 5. The top of the pipe is connected with the induced draft fan 11 and the chimney 12 in turn;

[0021] In the specific setting, the wet spray atomization layer 6 includes water pipes and atomization nozzles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com